When it comes to assembling structures with T-slot aluminum, there are some key considerations to keep in mind to ensure that your profile is structurally sound and meets your specific needs. Here are three important things to keep in mind when assembling T-slot aluminum structures.

Know the Types of T-slot Aluminum Accessories and Connectors

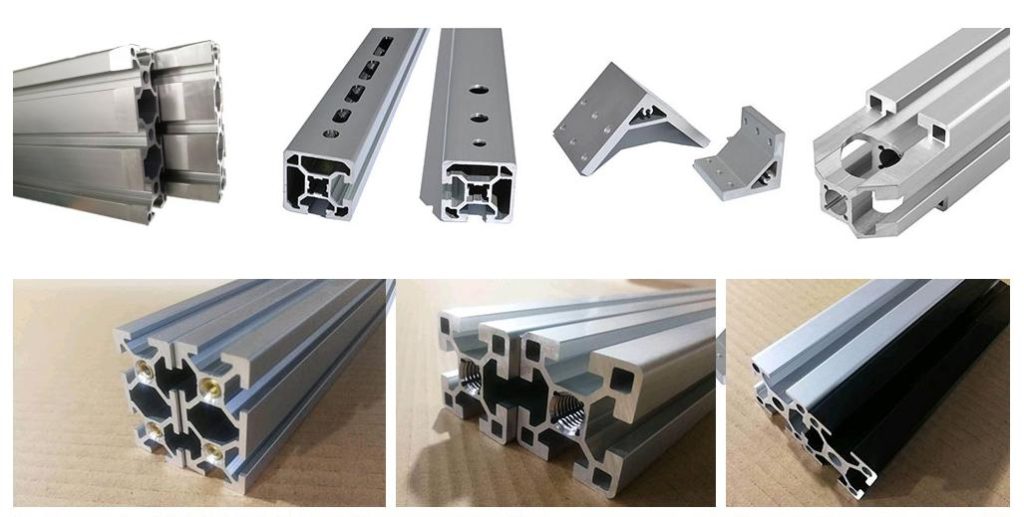

There are various types of T-slot aluminum accessories and connectors available in the market that are designed to fit with T-slot aluminum extrusions and facilitate easy construction of structures. Here are some common types of T-slot aluminum connectors and accessories:

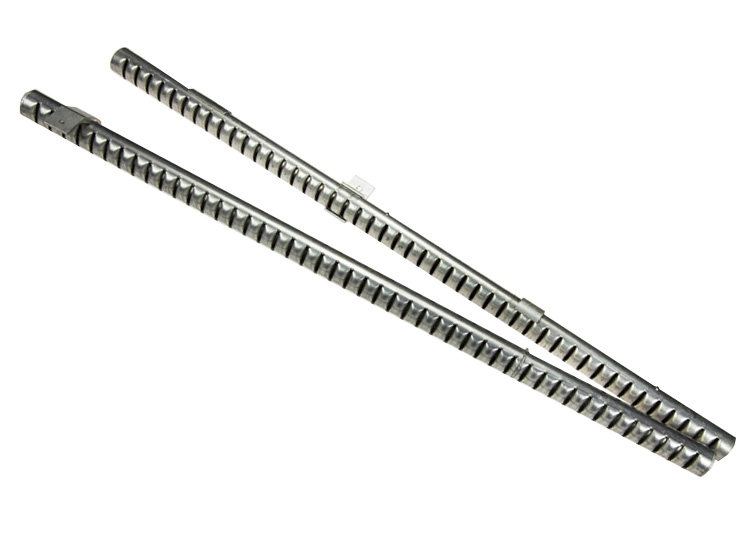

- T Nuts

T-nuts are one of the most common types of T-slot aluminum connectors. They are used to create connections between the extrusions and other components, such as brackets or panels.

- Corner connectors

Corner connectors are used to connect two or more T-slot aluminum extrusions at a corner angle. They come in various shapes and sizes to suit different applications.

- Joining plates

Joining plates are used to connect two or more T-slot aluminum extrusions end-to-end to create a longer section of the structure.

- Brackets

Brackets are used to connect T-slot aluminum extrusions to other components, such as panels or shelves.

- Hinges

Hinges are used to create moving sections in T-slot aluminum structures. They can be used to create doors or hinged panels.

- Handles and knobs

Handles and knobs can be used to enhance the functionality and convenience of T-slot aluminum structures, such as by making doors or drawers easier to open and close.

- Feet and casters

Feet and casters are used to provide stability and mobility to T-slot aluminum structures, such as workbenches or carts.

- End caps

End caps are used to cap off the ends of T-slot aluminum extrusions to provide a finished look and protect the ends from damage.

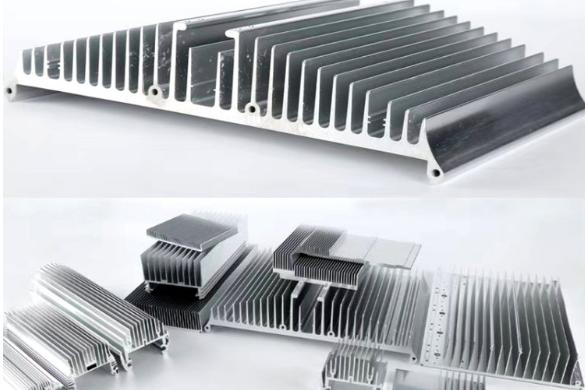

These are just some of the common types of T-slot aluminum connectors and accessories available in the market. There are many more options to choose from based on your specific needs and requirements.

Know How to Assembling T-slot Aluminum Structures

Assembling T-slot aluminum structures is a straightforward process that can be completed with basic hand tools. Here are the general steps involved in assembling T-slot aluminum structures:

- Gather materials

Before starting the assembly process, gather all necessary materials, including T-slot aluminum profiles, connectors, fasteners, and tools.

- Plan the design

Determine the design and layout of the structure, including the size and placement of each component. This will help ensure that all necessary materials are available and that the assembly process goes smoothly.

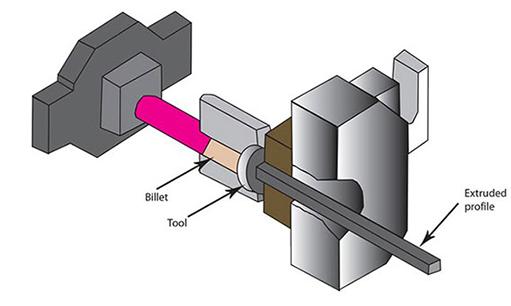

- Cut the profiles

Cut the T-slot aluminum profiles to the desired lengths using a saw or other cutting tool. Be sure to measure and mark the profiles carefully to ensure accurate cuts.

- Attach the connectors

Insert the connectors into the ends of the profiles, aligning the slots on the connector with the T-slot on the profile. Secure the connectors in place with screws or other fasteners.

- Assemble the structure

Connect the profiles and connectors together to create the desired structure. Use screws or other fasteners to secure the joints and ensure that the structure is stable and secure.

- Add accessories

Once the structure is assembled, add any necessary accessories such as panels, shelves, or brackets. These accessories can be attached to the T-slot using additional connectors and fasteners.

- Test the structure

Once the assembly is complete, test the structure to ensure that it is stable and secure. Make any necessary adjustments or modifications before using the structure for its intended purpose.

Overall, assembling T-slot aluminum structures is a relatively simple and straightforward process that can be completed with basic hand tools. With proper planning and attention to detail, T-slot aluminum structures can be designed and assembled to meet the specific needs of a wide range of applications.

Know Common Mistakes and Tips to Maintaining and Cleaning T-slot Aluminum Structures

Here are some common mistakes to avoid when maintaining and cleaning T-slot aluminum structures:

- Using harsh chemicals

Avoid using harsh chemicals, such as acids or alkalis, as they can damage the surface of the aluminum and reduce its lifespan. Use a mild detergent and water instead.

- Scrubbing with abrasive materials

Do not use abrasive materials, such as steel wool, to clean the aluminum, as they can scratch the surface and damage the finish. Instead, use a soft cloth or sponge.

- Neglecting to lubricate moving parts

Neglecting to lubricate moving parts, such as joints or hinges, can result in increased friction and wear, leading to damage or failure of the structure.

- Not inspecting the structure regularly

Failure to inspect the T-slot aluminum structure regularly can result in missed signs of wear or damage. Addressing issues early can prevent further damage or failure.

- Storing the structure improperly

Improper storage, such as exposing the structure to moisture or direct sunlight, can damage the aluminum and reduce its lifespan.

By avoiding these common mistakes, you can ensure that your T-slot aluminum structures remain in good condition and operate effectively for a long time. Regular maintenance and cleaning are essential for the longevity and optimal performance of T-slot aluminum structures.

In conclusion, assembling T-slot aluminum structures can be a simple and efficient process, as long as you keep in mind the key considerations discussed in this article. With a little planning and attention to detail, you can create custom structures that are perfectly tailored to your specific needs.

Related Products

Related Articles