Introduction

7075 aluminum pipe is the hardest and strongest among ordinary civilian aluminum alloy pipes and has good machining performance. It is widely used in various mechanical parts, pressure pipes, outdoor products, sporting goods, fixtures, hardware products, electronics, electrical appliances, etc. But what elements should be considered during the process of 7075 aluminum pipe?

What is 7075 Aluminum Alloy?

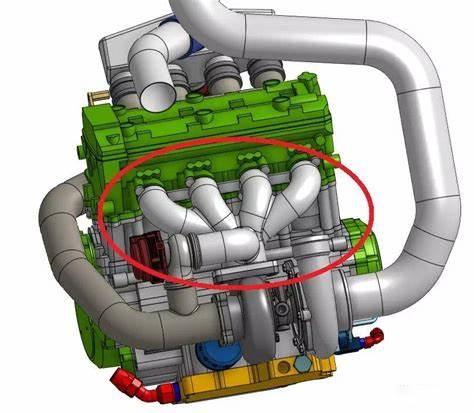

7075 aluminum alloy is a cold-treated forged alloy with high strength, far superior to mild steel. 7075 Aluminum is one of the strongest alloys on the market. General corrosion resistance, high mechanical properties, and anodic reaction. Smaller grains enable deeper drilling performance, higher tool wears resistance, and excellent thread rolling. Zinc is the main alloying element in 7075. Adding magnesium to the alloy containing 3%-7.5% zinc can form MgZn2 with a significant strengthening effect so that the heat treatment effect of the alloy is much better than that of the aluminum-zinc binary alloy. With the increase of zinc and magnesium content, the tensile strength of the alloy will further increase, but the resistance to stress corrosion and exfoliation corrosion will decrease. Under heat treatment, high strength properties can be achieved.

The 7075 material is generally added with a small amount of copper, chromium, and other alloys. Among them, the 7075-T651 aluminum alloy is of particularly high quality, known as the best aluminum alloy product, with high strength, far better than any mild steel as well as good mechanical properties and anodic reaction.

It is commonly used in aerospace, mold processing, mechanical equipment, and fixtures. It is especially suitable for high-stress structures that require high strength and corrosion resistance such as aircraft structures.

Process of 7075 Aluminum Tube

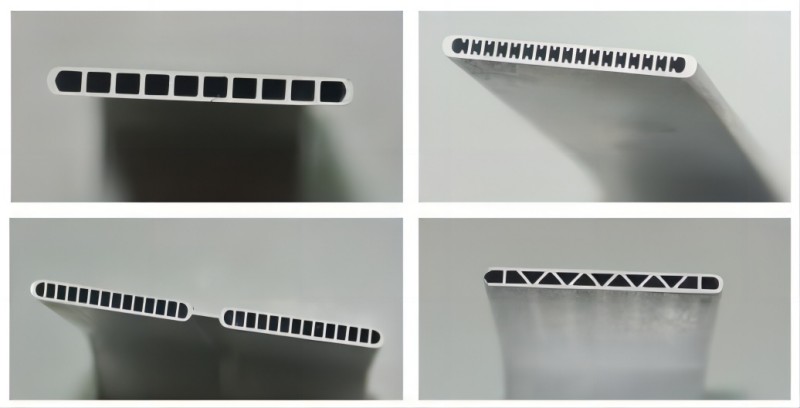

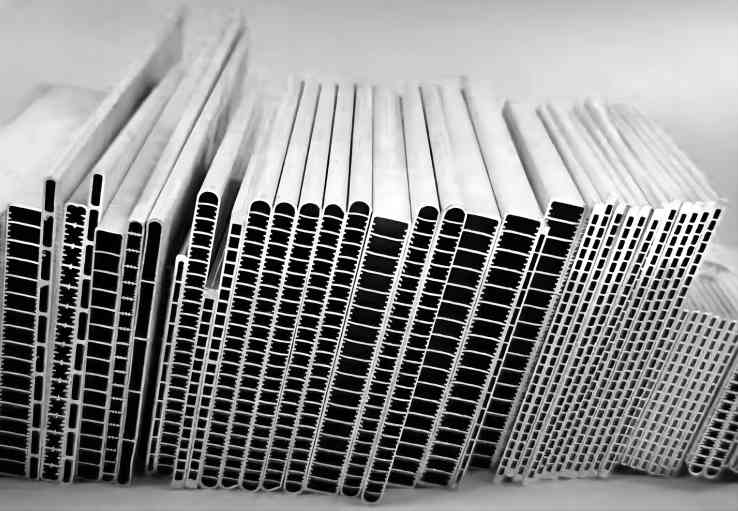

7075 aluminum tube is a smooth aluminum tube, which generally adopts the perforation extrusion method, because the smooth aluminum tube has a small specific gravity, is easy to process, and has high mechanical strength. The production process of the smooth aluminum tube is relatively strict and meticulous. However, several issues should be paid attention to during production to produce smooth aluminum tubes with high quality.

Large seamless aluminum tubes are generally formed by hot extrusion and then undergo subsequent failure treatment. Small seamless aluminum tubes can be subjected to subsequent failure treatment after hot pressing or cold drawing. The alumina hydrate produced in the production process of the smooth aluminum tube requires continuous extrusion, which is severely dehydrated during the extrusion process, resulting in the formation of trachoma. To prevent the trachoma of the smooth aluminum pipe, the round aluminum pipe for extrusion should not be cracked. It cannot be stored in a humid environment, the sodium hydroxide content in the cleaning solution is about 30%, and the aluminum ion content in the cleaning solution should be strictly controlled.

What is the price of a 7075 Aluminum Tube?

7075 aluminum tube is a widely used ultra-high strength aviation aluminum tube material. The specification range of 7075 aluminum tubes is generally 4 mm to 500 mm. It can be divided into 7075-T6 aluminum tube, 7075-T6511 aluminum tube, 7075-O aluminum tube, 7075 aluminum tube -t655 meters, according to different processing techniques, generally extruded 7075-t655 meters The prices of 7075 aluminum tubes currently on the market are basically different. The following five factors mainly determine its price.

- The price of 7075 aluminum rods varies according to the specification. Generally, the price of 7075 aluminum rods with a diameter between 10 and 150 mm is lower, and the price of smaller or larger than this range is slightly higher. In particular, the smaller the diameter, the higher the price.

- The price of ordinary 7075 aluminum rods is lower than the price of precision drawn 7075 aluminum rods.

- The price of aluminum rods in the 7075-T6 condition is lower than that of the 7075 aluminum rods in the 7075-T6511 condition.

- Due to different transportation distances, the transportation cost of aluminum rods is different, and the price is also different.

- Due to the different origins of 7075 aluminum rods, the price of imported 7075 aluminum rods is higher than that of domestic 7075 aluminum rods. The price of 7075 aluminum rods of Dongbeiguang and Southwest Aluminum is also higher than that of other enterprises. Generally speaking, the higher the processing, the higher the quality and the stable quality, and most of them are used in stricter cases.

Conclusion

CHAL is a supplier of aluminum foils, aluminum sheets, and other products of aluminum alloy. We offer individualized services for aluminum processing materials to meet the needs of each client and to offer the highest assurance for the creation of your products. Please contact us freely if you require high-quality and reasonably priced aluminum sheets, foils, tubes, etc.; we’ll be your best choice.