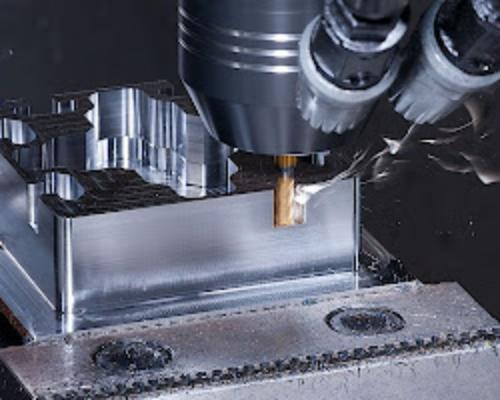

Aluminum machining is a versatile process that can be used to produce a wide variety of parts. The specific type of aluminum machining part that is used will depend on the specific application and the requirements of the part. This article will discuss the different types and applications of aluminum machining parts. It will also discuss the factors to consider when choosing an aluminum machining part.

What are the Different Types of Aluminum Machining Parts?

There are many different types of aluminum machining parts, each with its own unique properties and applications. Some of the most common types of aluminum machining parts include:

- Structural parts: These parts are used to support other components or assemblies. They are typically made from high-strength aluminum alloys and are often used in the aerospace, automotive, and construction industries.

- Machined components: These parts are used in a variety of machines and appliances. They are typically made from high-precision aluminum alloys and are often used in the medical, electronics, and manufacturing industries.

- Precision parts: These parts are used in applications where high accuracy and precision are required. They are typically made from high-grade aluminum alloys and are often used in the aerospace, medical, and defense industries.

- Formed parts: These parts are made by shaping aluminum sheet metal or plate. They are typically used in a variety of applications, such as automotive, appliance, and furniture manufacturing.

- Cast parts: These parts are made by pouring molten aluminum into a mold. They are typically used in applications where high strength and durability are required.

- Extruded parts: These parts are made by forcing molten aluminum through a die. They are typically used in applications where long, straight sections are required.

The specific type of aluminum machining part that is used will depend on the specific application and the requirements of the part.

What are the Applications of Aluminum Machining Parts?

Aluminum machining parts are used in a wide variety of applications, including:

- Aerospace: Aluminum machining parts are used in a variety of aircraft components, such as landing gear, airframes, and engines.

- Automotive: Aluminum machining parts are used in a variety of automotive components, such as engine blocks, transmissions, and suspension components.

- Medical: Aluminum machining parts are used in a variety of medical devices, such as implants, prostheses, and surgical instruments.

- Electronics: Aluminum machining parts are used in a variety of electronic devices, such as computers, cell phones, and TVs.

- Manufacturing: Aluminum machining parts are used in a variety of manufacturing machines and tools.

- Construction: Aluminum machining parts are used in a variety of construction materials, such as windows, doors, and siding.

- Consumer products: Aluminum machining parts are used in a variety of consumer products, such as appliances, furniture, and sporting goods.

The specific use of an aluminum machining part will depend on the specific application and the requirements of the part.

How to Choose the Type of Aluminum Machining Parts?

Here are some of the factors that will be considered when choosing the type of aluminum machining part to use:

- The strength and durability requirements of the part: Some parts need to be strong and durable, while others do not.

- The accuracy and precision requirements of the part: Some parts need to be very accurate and precise, while others do not.

- The cost of the part: The cost of the part will vary depending on the type of part and the complexity of the manufacturing process.

- The availability of the part: Some types of parts may not be available in all areas.

Conclusion

Aluminum machining parts are used in a wide variety of applications, including aerospace, automotive, medical, electronics, manufacturing, construction, and consumer products. The versatility of aluminum makes it a valuable material for a wide range of applications. By considering the factors above, you can choose the type of aluminum machining part that is best suited for your application.