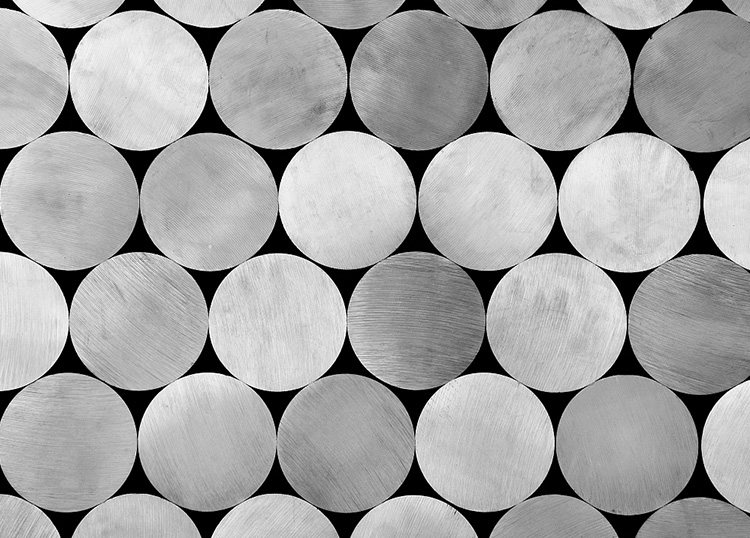

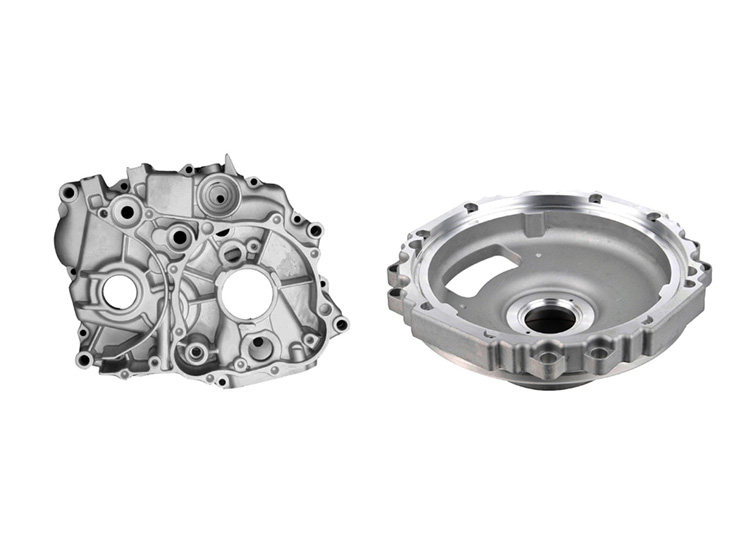

Aluminum machining is the process of shaping aluminum parts using cutting tools. It is a versatile process that can be used to produce a wide variety of parts, from simple shapes to complex geometries.

The tolerances and surface finishes achievable with aluminum machining depend on a number of factors, including the type of aluminum alloy, the machining process, the tooling used, and the skill of the operator.

Types of Aluminum Machining Processes

There are many different types of aluminum machining processes, each with its own advantages and disadvantages. Some of the most common aluminum machining processes include:

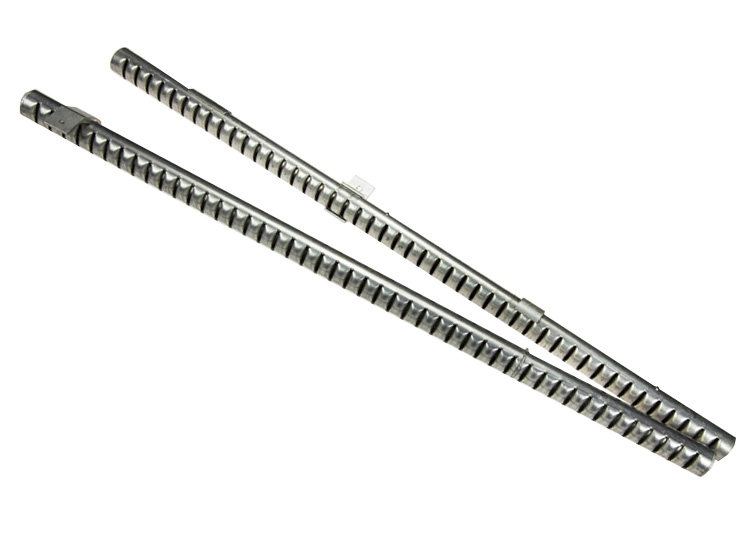

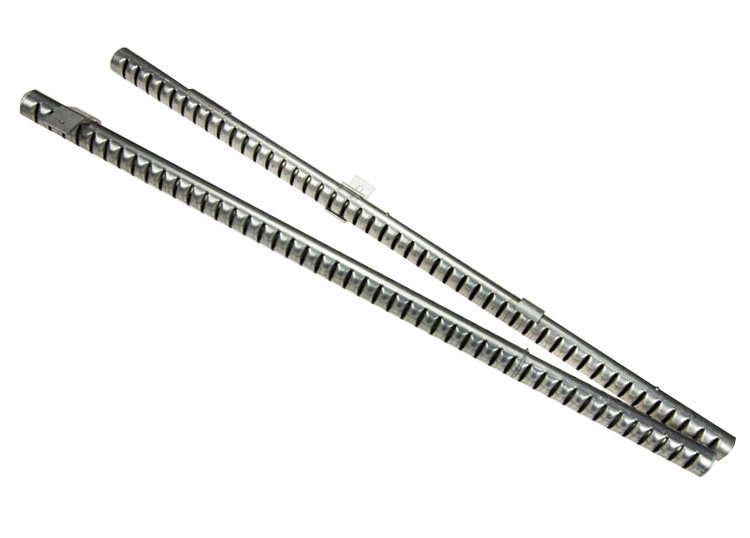

- Turning: Turning is a process in which a rotating tool is used to remove material from a rotating workpiece. Turning can be used to produce a variety of cylindrical shapes, such as shafts, tubes, and disks.

- Milling: Milling is a process in which a rotating cutter is used to remove material from a stationary workpiece. Milling can be used to produce a variety of shapes, including flat surfaces, slots, and holes.

- Drilling: Drilling is a process in which a rotating drill bit is used to create holes in a workpiece. Drilling can be used to create holes of various sizes and shapes.

- Grinding: Grinding is a process in which a rotating abrasive wheel is used to remove material from a workpiece. Grinding can be used to produce very smooth and accurate surfaces.

- Sawing: Sawing is a process in which a rotating saw blade is used to cut through a workpiece. Sawing can be used to cut a variety of shapes, including straight lines, curves, and holes.

Factors Affecting Tolerances and Surface Finishes

The tolerances and surface finishes achievable with aluminum machining depend on a number of factors, including:

- The type of aluminum alloy: Different aluminum alloys have different machinability characteristics. Some alloys are easier to machine than others, and will produce better tolerances and surface finishes.

- The machining process: Different machining processes produce different tolerances and surface finishes. For example, CNC machining can produce very tight tolerances and good surface finishes, while sawing can produce wider tolerances and rougher surface finishes.

- The tooling used: The tooling used also affects the tolerances and surface finishes achievable. High-quality tooling will produce better results than low-quality tooling.

- The skill of the operator: The skill of the operator also plays a role in the achievable tolerances and surface finishes. A skilled operator will be able to produce better results than an unskilled operator.

Tolerances Achievable with Aluminum Machining

The tolerances achievable with aluminum machining can be very tight. For example, CNC machining can achieve tolerances of ±0.001″ (0.025 mm). However, the achievable tolerances will also depend on the specific machining process and the tooling used.

In general, the tighter the tolerances, the more difficult they are to achieve. This is because tighter tolerances require more precise machining operations.

The cost of achieving tight tolerances can also be higher. This is because more precise tooling and machining operations are required.

The following table shows some typical tolerances for aluminum machining:

| Machining Process | Tolerance (in.) | Tolerance (mm) |

| Turning | ±0.001″ | ±0.025 mm |

| Milling | ±0.002″ | ±0.05 mm |

| Drilling | ±0.003″ | ±0.08 mm |

| Grinding | ±0.0005″ | ±0.0125 mm |

Surface Finishes Achievable with Aluminum Machining

The surface finishes achievable with aluminum machining can also be very good. For example, CNC machining can achieve surface finishes of Ra 0.4 μm (20 microinches). However, the achievable surface finish will also depend on the specific machining process and the tooling used.

In general, the smoother the surface finish, the more difficult it is to achieve. This is because smoother surface finishes require more precise machining operations.

The cost of achieving a smooth surface finish can also be higher. This is because more precise tooling and machining operations are required.

The following table shows some typical surface finishes for aluminum machining:

| Machining Process | Surface Finish (Ra) |

| Turning | Ra 3.2 μm |

| Milling | Ra 1.6 μm |

| Drilling | Ra 0.8 μm |

| Grinding | Ra 0.4 μm |

Conclusion

The tolerances and surface finishes achievable with aluminum machining are very good. This makes aluminum a versatile material that can be used to produce a wide variety of high-precision parts.

When choosing an aluminum machining process, it is important to consider the desired tolerances and surface finishes. The type of aluminum alloy, the tooling used, and the skill of the operator will also affect the achievable tolerances and surface finishes.