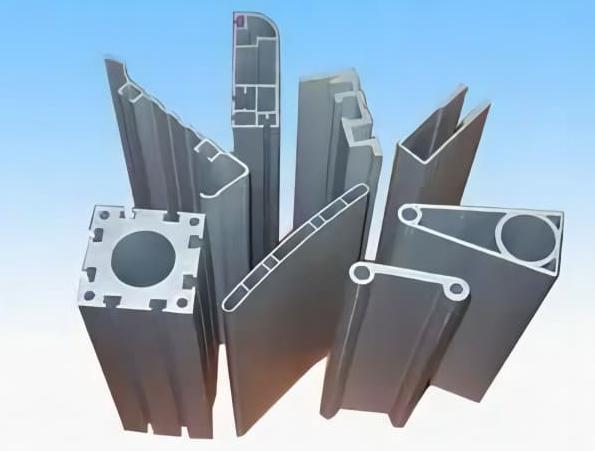

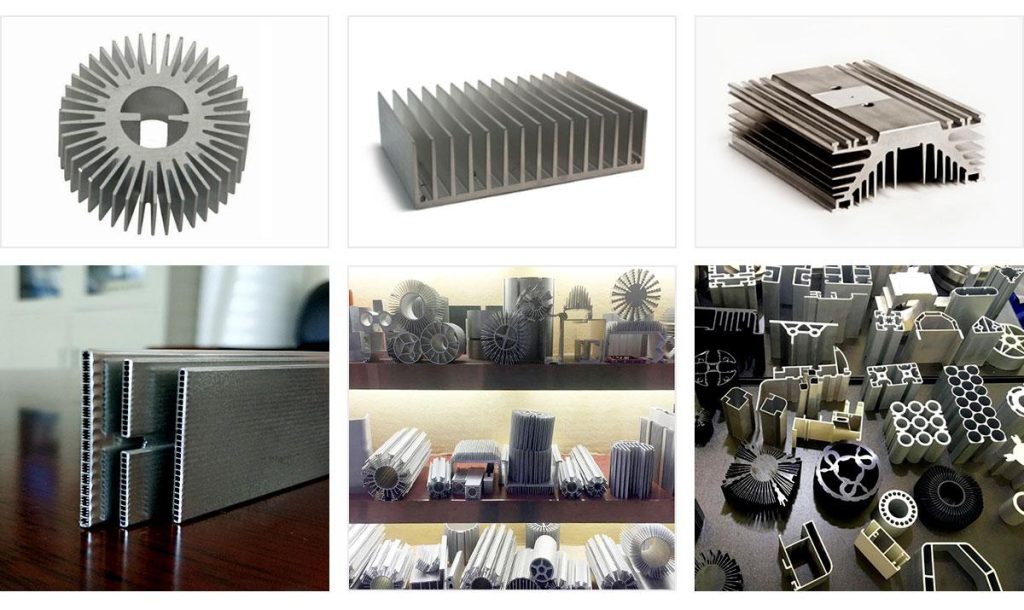

In the world of industrial and DIY projects, T-slot aluminum extrusions have gained significant popularity for their versatility, strength, and ease of use. T-slot aluminum profiles, characterized by their T-shaped slots, serve as a robust framework for a variety of applications. In this article, we will explore the advantages of using T-slot aluminum, the methods of T-slot aluminum connection, and how to effectively use T-slot aluminum connectors.

Advantages of T-Slot Aluminum

T-slot aluminum extrusions offer numerous advantages across a variety of applications, making them a popular choice for engineers, builders, and DIY enthusiasts. Here are some key advantages of T-slot aluminum:

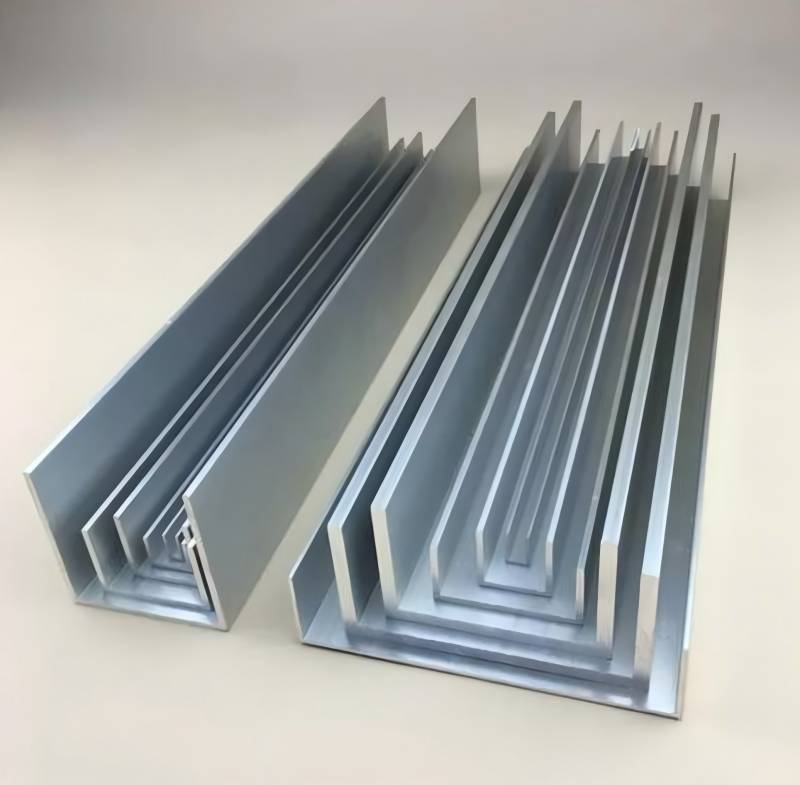

- Modularity and Flexibility: T-slot aluminum extrusions are designed with a modular structure, allowing for easy assembly and disassembly. This modularity enables flexibility in design, making it simple to modify or expand structures without the need for specialized tools.

- Strength and Durability: T-slot aluminum profiles are known for their high strength-to-weight ratio. The material is lightweight but incredibly durable, making it suitable for a wide range of applications, from industrial machinery to custom furniture.

- Versatility in Design: The T-shaped slots along the extrusions offer a convenient means of attaching accessories, components, and panels. This versatility allows users to create complex and customized structures tailored to their specific needs.

- Ease of Assembly: Unlike traditional welding or complex fastening methods, T-slot aluminum connection involves simple bolted joints. This ease of assembly not only reduces labor and time but also makes it accessible to individuals with varying levels of technical expertise.

Methods of T-Slot Aluminum Connection:

T-slot aluminum connections are versatile and can be achieved through various methods, providing flexibility in design and assembly. Here are some common methods of T-slot aluminum connection:

- Standard Fastening with Bolts and Nuts: This is the most straightforward and widely used method. T-slot aluminum profiles come with T-shaped slots that allow for the insertion of bolts. Nuts are then tightened onto the bolts, creating a secure connection. This method is simple, reliable, and easy to disassemble if needed.

- Slide-in T-Nuts: Many T-slot aluminum profiles are designed to accommodate T-nuts, which can slide along the T-shaped slots. The nuts have tabs that fit into the slots, allowing for easy positioning. After placing the T-nuts in the desired locations, bolts are inserted and tightened to secure the connection. This method is particularly efficient as it eliminates the need for precise nut placement.

- Angle Connectors: Angle connectors are specialized components designed to join T-slot aluminum profiles at different angles, typically 90 degrees. These connectors simplify the creation of corners, frames, or multi-dimensional structures. They often have built-in T-nuts, allowing for easy attachment using bolts.

- Anchor Fasteners: Anchor fasteners are similar to standard bolts but are designed with a flanged head that sits inside the T-slot. These anchor fasteners can be slid into the T-shaped slot and then turned to anchor themselves in place. This method provides a secure connection without requiring access to the end of the slot.

- Corner Brackets: Corner brackets are L-shaped connectors designed to join two T-slot aluminum profiles at a right angle. They usually have T-nuts or holes for bolts, making it easy to create corners in a structure. This method is ideal for constructing frames or enclosures.

- Drop-in T-Bolts: Some T-slot aluminum profiles have slots designed to accept T-bolts. These T-bolts have a head shaped like a T, allowing them to be dropped into the T-shaped slot. Once in place, the bolt is turned to secure it, providing a strong and adjustable connection.

- Panel Connectors: Panel connectors are specialized connectors designed for attaching panels, screens, or other flat components to T-slot aluminum structures. These connectors often have clips or brackets that can be inserted into the T-shaped slots, providing a secure attachment point for panels.

- End Fastening: In situations where access to the end of the T-slot is possible, fastening can be achieved using end connectors. These connectors are inserted into the end of the T-slot and secured with bolts, providing a strong connection point.

When choosing a method of T-slot aluminum connection, factors such as the specific application, load requirements, and ease of assembly/disassembly should be considered. The versatility of these connection methods allows for creative and efficient solutions in a wide range of projects.

How to Use T-Slot Aluminum Connectors?

Using T-slot aluminum connectors is a straightforward process, and it typically involves a few simple steps. The specific method may vary slightly depending on the type of connector you are using, but the following general guidelines should help you understand how to use T-slot aluminum connectors effectively:

Materials Needed:

- T-slot aluminum profiles

- T-slot aluminum connectors

- Bolts

- Nuts

- Wrench or Allen key (depending on the type of fastener)

Steps of Using T-Slot Aluminum Connectors

- Select the Right Profile: Choose T-slot aluminum profiles that match the specifications and dimensions required for your project. Profiles are available in various sizes and shapes, allowing for customization based on load-bearing requirements and design preferences.

- Prepare the Connection Points: Ensure that the T-shaped slots are clear of debris or obstructions. This step is crucial for the smooth insertion of T-nuts or other connectors. Proper preparation ensures a secure and reliable connection.

- Insert T-Nuts or Connectors: Depending on the chosen method of connection, insert T-nuts into the T-shaped slots or attach specialized connectors. Ensure that they are positioned according to the design requirements.

- Secure with Bolts and Nuts: Place bolts through the T-nuts or connectors and align them with the corresponding holes on the profiles. Tighten the nuts using the appropriate tools until the connection is secure. Take care not to overtighten, as this may damage the profiles.

- Check for Alignment and Stability: After securing the connection, check for proper alignment and stability. Ensure that the components are securely fastened and that the structure meets design specifications.

Conclusion:

In conclusion, the remarkable adaptability and structural prowess of T-slot aluminum extrusions underscore their pivotal role in shaping modern design and construction landscapes. As we unravel the advantages, diverse connection methods, and effective usage of T-slot aluminum, it is evident that these systems have become indispensable in a wide array of applications. The synergy of user-friendly assembly and robust design principles positions T-slot aluminum as a go-to solution for projects ranging from industrial frameworks to intricate DIY endeavors. Integral to this success are the T-slot aluminum extrusion manufacturers, whose commitment to quality and innovation ensures a steady supply of materials that empower engineers, builders, and creators to realize their visions with precision and reliability. Moving forward, the collaborative efforts between designers and T-slot aluminum extrusion manufacturers will continue to drive progress and set new benchmarks in the ever-evolving landscape of construction and fabrication.