The relentless march of technology brings with it ever-increasing processing power and functionality. This progress, however, generates a significant byproduct: heat. In the world of electronics and machinery, excessive heat buildup can lead to malfunctions, reduced lifespans, and even complete system failure. To combat this challenge, engineers rely on a crucial component – the heat sink.

Among various heat sink materials, aluminum stands out as a reliable and versatile workhorse. This article delves into the reasons behind aluminum’s dominance in heat dissipation applications across diverse industries.

The Power of Aluminum: A Winning Combination of Properties

Aluminum’s effectiveness in heat dissipation stems from a potent combination of physical properties. Here’s a closer look at the key factors:

- Thermal Conductivity: One of the most critical properties for heat sink materials is thermal conductivity. This metric indicates a material’s ability to transfer heat from a hot source to a cooler area. Aluminum, while not the absolute best conductor (copper boasts a higher rating), offers excellent thermal conductivity that efficiently carries heat away from electronic components. This efficient heat transfer prevents components from reaching critical temperatures, ensuring smooth operation.

- Lightweight Champion: Weight is a crucial consideration in many applications, particularly consumer electronics like laptops and mobile devices. Aluminum shines in this aspect due to its low density. Compared to other materials with similar thermal conductivity, aluminum heat sinks significantly reduce weight without sacrificing cooling performance. This translates to lighter, more portable devices that are easier to carry and use.

- Cost-Effectiveness: Economic factors play a vital role in real-world applications. Aluminum is a relatively inexpensive metal compared to other high thermal conductivity options like copper. This cost advantage makes aluminum heat sinks an attractive choice for manufacturers, allowing for the production of cost-effective yet efficient cooling solutions.

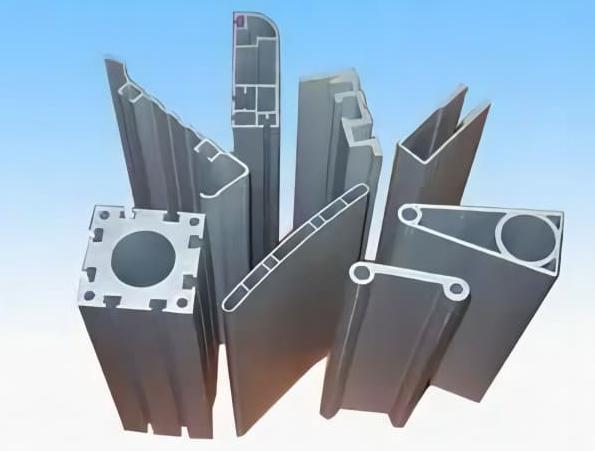

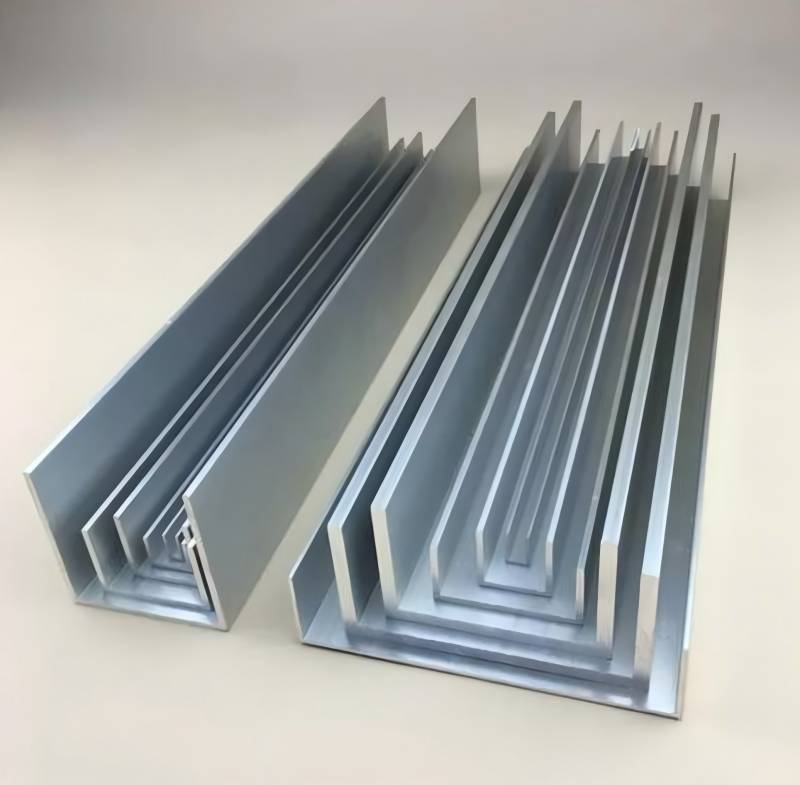

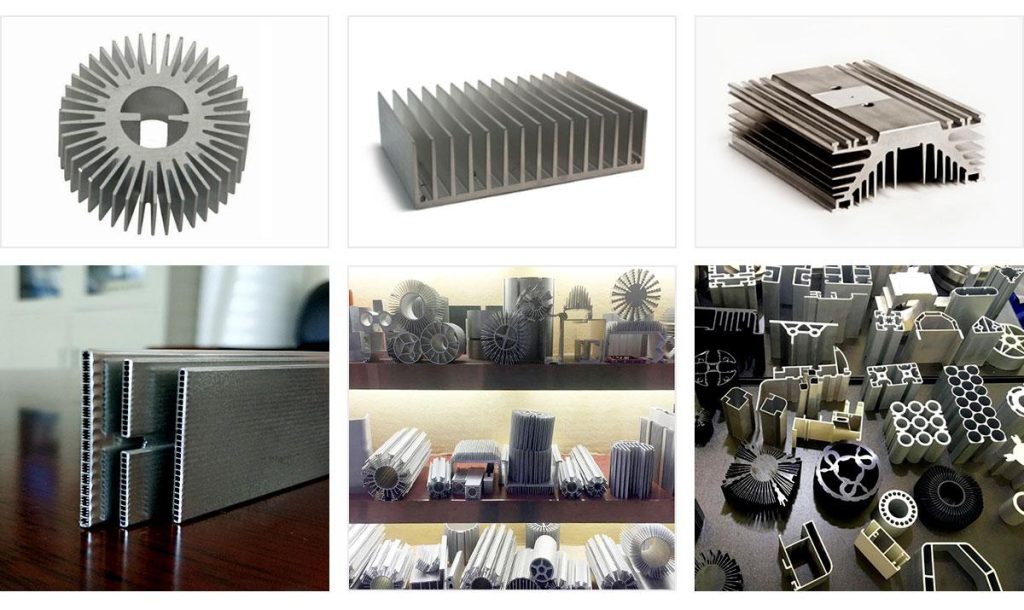

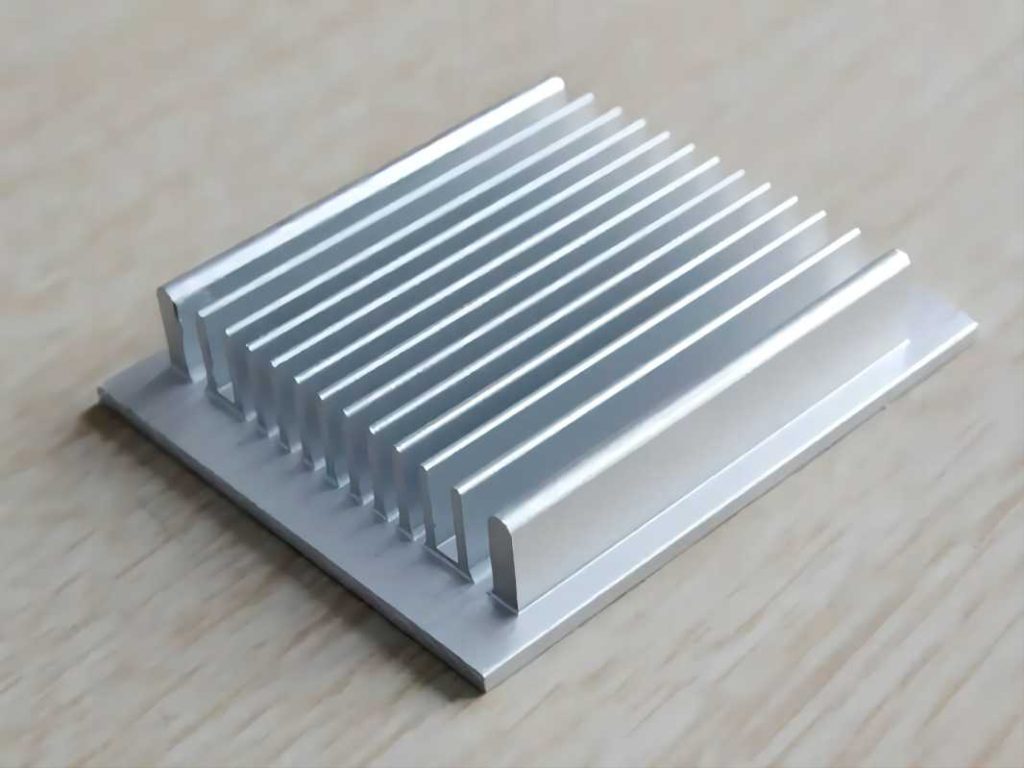

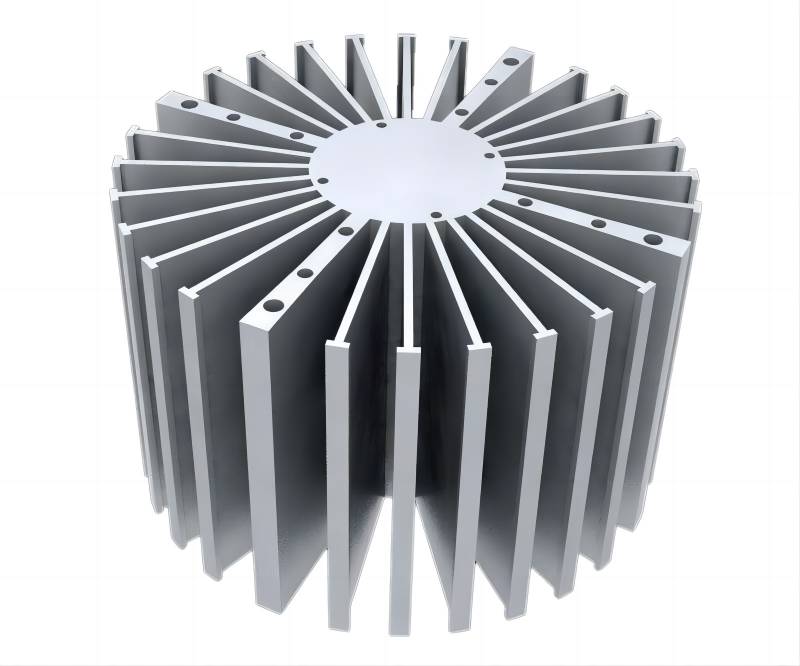

- Shaping Up for Success: Heat sinks come in various shapes and sizes depending on the application. Aluminum’s malleability makes it ideal for extrusion processes. This allows manufacturers to create heat sinks with intricate fin designs that maximize surface area for efficient heat transfer. The versatility of aluminum enables the creation of customized heat sinks perfectly suited for specific cooling requirements.

Aluminum Heat Sinks Across Industries: Keeping Everything Cool

The unique properties of aluminum make it a highly sought-after material for heat sinks across a wide range of industries. Let’s explore some specific applications:

- Consumer Electronics: The world of consumer electronics relies heavily on aluminum heat sinks to keep devices cool. Laptops, desktops, and gaming consoles all generate significant heat, particularly from their central processing units (CPUs) and graphics processing units (GPUs). Aluminum heat sinks are strategically placed over these components to absorb and disperse the heat, preventing overheating and ensuring optimal performance. Even within the realm of gaming consoles, where intense graphics processing generates substantial heat, aluminum heat sinks are employed to maintain system stability and prevent performance throttling.

- Automotive Industry: Heat management is crucial in vehicles to maintain optimal engine performance and reliability. Aluminum heat sinks find various applications within the automotive industry. One key area is in engine control units (ECUs), the electronic brains of modern cars. ECUs constantly process information and make critical decisions, and efficient heat dissipation is essential for their proper functioning. Aluminum heat sinks are also employed in power modules within vehicles, regulating and distributing electrical power. With the growing adoption of LED lighting systems in cars, aluminum heat sinks play a role here as well, ensuring the LEDs don’t overheat and maintain their brightness over time.

- Telecommunication Industry: The backbone of our digital world, telecommunication equipment like base stations and servers generate significant heat due to the constant processing and data transfer. Here, aluminum heat sinks step in to dissipate this heat and ensure smooth operation. Efficient heat management is vital for maintaining network stability and preventing outages. By keeping telecommunication equipment cool, aluminum heat sinks contribute to the seamless flow of information across the globe.

- Medical Devices: Modern medical devices, like MRI machines and lasers, often require precise temperature control for accurate functionality and patient safety. Aluminum heat sinks are incorporated into these devices to efficiently dissipate heat, ensuring they operate within safe temperature ranges. In MRI machines, for example, heat buildup can lead to image distortion, compromising diagnostic accuracy. Aluminum heat sinks help prevent this by efficiently transferring heat away from critical components.

- LED Lighting: While lauded for their energy efficiency, LED lights still generate heat during operation. This heat buildup can shorten the lifespan of the LEDs. To address this challenge, aluminum heat sinks are integrated into LED lighting fixtures. By absorbing and dispersing heat, aluminum heat sinks extend the lifespan of the LEDs, ensuring long-lasting, energy-efficient illumination.

- Industrial Applications: Industrial settings are filled with machinery and equipment that generate significant heat as a byproduct of their operation. Power electronics, motor drives, and industrial control systems all rely on efficient heat dissipation to function properly. Aluminum heat sinks are widely used in these applications to maintain optimal operating temperatures and prevent malfunctions. By keeping industrial equipment cool, aluminum heat sinks contribute to smooth production processes, minimize downtime for maintenance and repairs, and ultimately extend the lifespan of the equipment itself.

Conclusion

In conclusion, aluminum heat sinks offer a compelling combination of benefits: excellent thermal conductivity for efficient heat transfer, lightweight construction for portability, cost-effectiveness for widespread adoption, and remarkable versatility in design. These advantages make them the workhorse of heat dissipation across a vast array of industries, from the consumer electronics in our hands to the industrial giants powering our world. While some applications might require even higher thermal conductivity, necessitating alternative materials like copper, aluminum remains the dominant choice due to its well-rounded properties and affordability. As technology continues to evolve and generate even more heat, the role of aluminum heat sinks will undoubtedly remain crucial in ensuring the reliable and efficient operation of electronics and machinery for years to come.