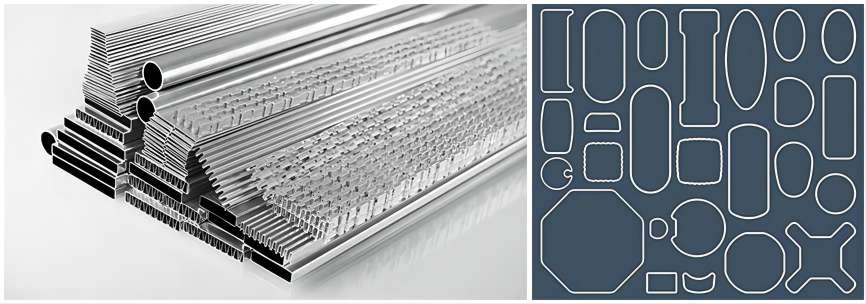

What Are the Aluminium for Cars?

Aluminium for cars, to put it simply, refers to aluminum and aluminum alloy materials used in the automobile manufacturing process. With the development of the modern automobile industry, higher requirements…

How to Ensure the Quality of Aluminium HFW Pipes

High-frequency welding is a widely used technique for producing aluminium welded tubes and HFW pipes. This process involves heating the edges of the tube with high-frequency current, followed by pressure…

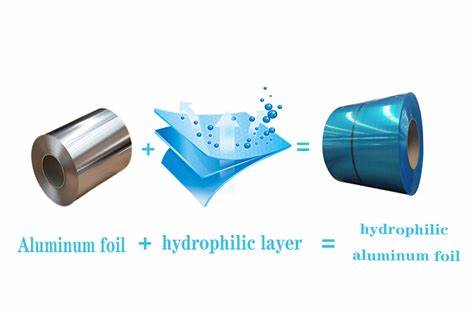

Hydrophilic Aluminum Foil: Enhancing Efficiency and Sustainability

Hydrophilic aluminum foil is a game-changing material widely used in industries such as air conditioning, refrigeration, and packaging. Known for its unique properties and versatility, it significantly improves efficiency, durability, and…

How to Paint on Aluminum Surfaces?

Painting on aluminum surfaces is a common surface treatment process, which can make aluminum products more beautiful, improve their corrosion resistance, and extend their service life. Whether it is aluminum doors…

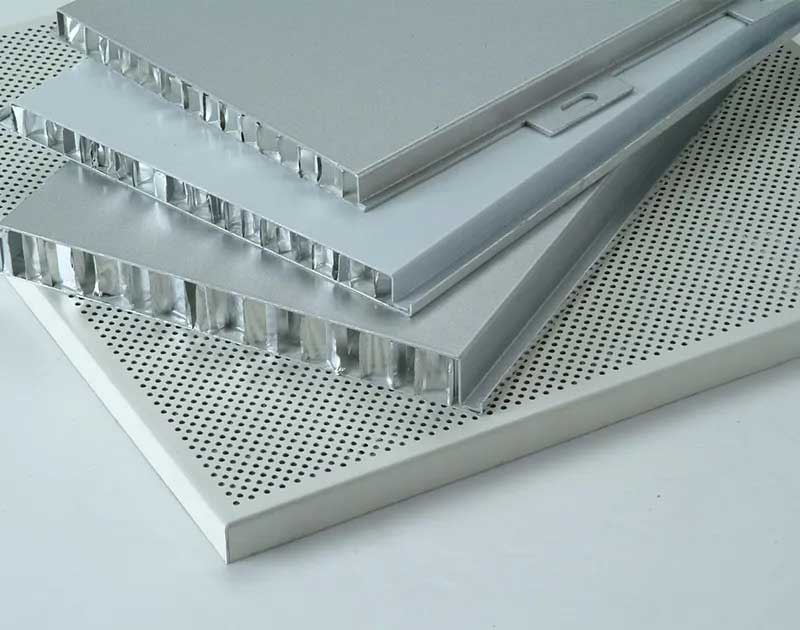

Aluminum Honeycomb Panel: Installation Methods and Key Considerations

Aluminum honeycomb panels are widely recognized for their lightweight, durable, and aesthetically pleasing properties. These panels are extensively used in construction, interior design, transportation, and other industries. Their strength-to-weight ratio, flatness,…

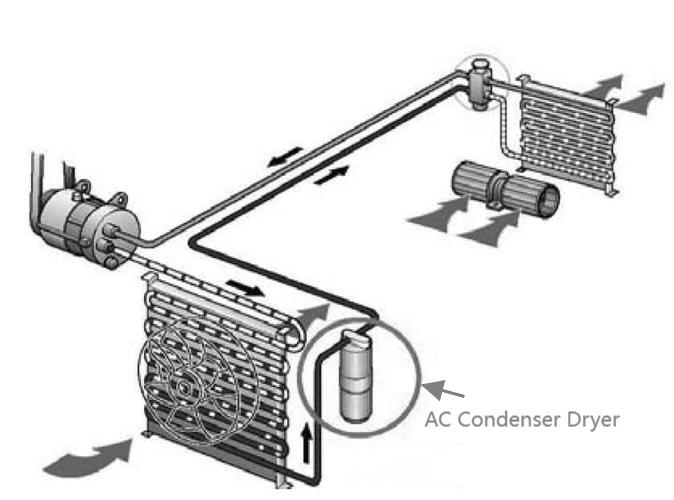

How to Spotting and Solve Condenser Dryer Issues in Your Car

The car air conditioning system plays a vital role in the comfort of the car, and the condensation dryer is an indispensable part of the car air conditioning system. It…

Aluminium Scaffold Tube: A Perfect Solution for Scaffolding Needs

Scaffolding has long been an essential component of construction, enabling workers to safely access elevated areas, transport materials, and carry out various tasks. Among the many types of scaffolding materials…

Are Aluminum High-Pressure Gas Cylinders Safe?

High-pressure gas cylinders are indispensable in various industries, ranging from medical and industrial applications to recreational activities like scuba diving. Among the many materials used for cylinder construction, aluminum has gained…

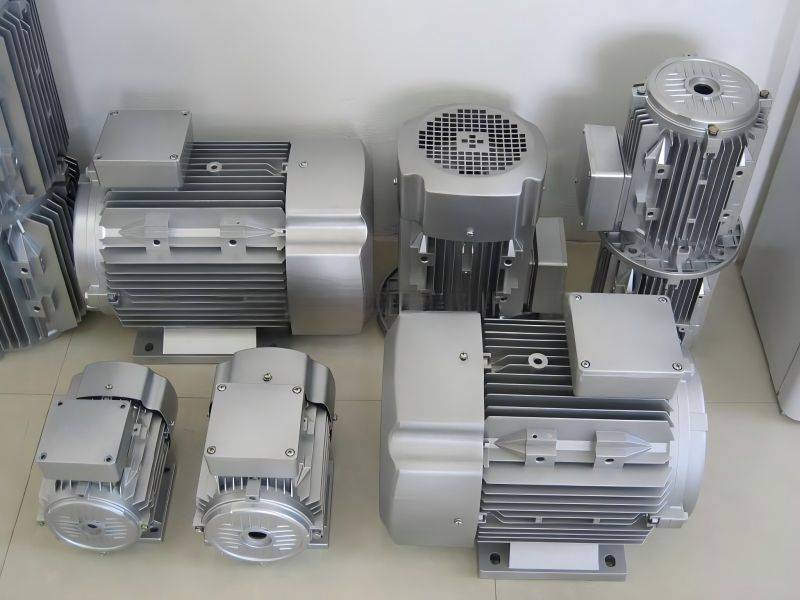

Aluminum Motor Housings: Application Fields and Manufacturing Processes

Aluminum motor housings have gained significant importance in various industries due to their excellent performance characteristics. The lightweight, corrosion-resistant, and thermally conductive properties of aluminum make it an ideal material for…

Comparing 7050 and 7075 Stamped Aluminum Parts in Aircraft Structure

Aluminum alloys play a crucial role in the aerospace industry, known for their high strength-to-weight ratios, durability, and adaptability. Among the most prominent choices for structural components in aircraft are…

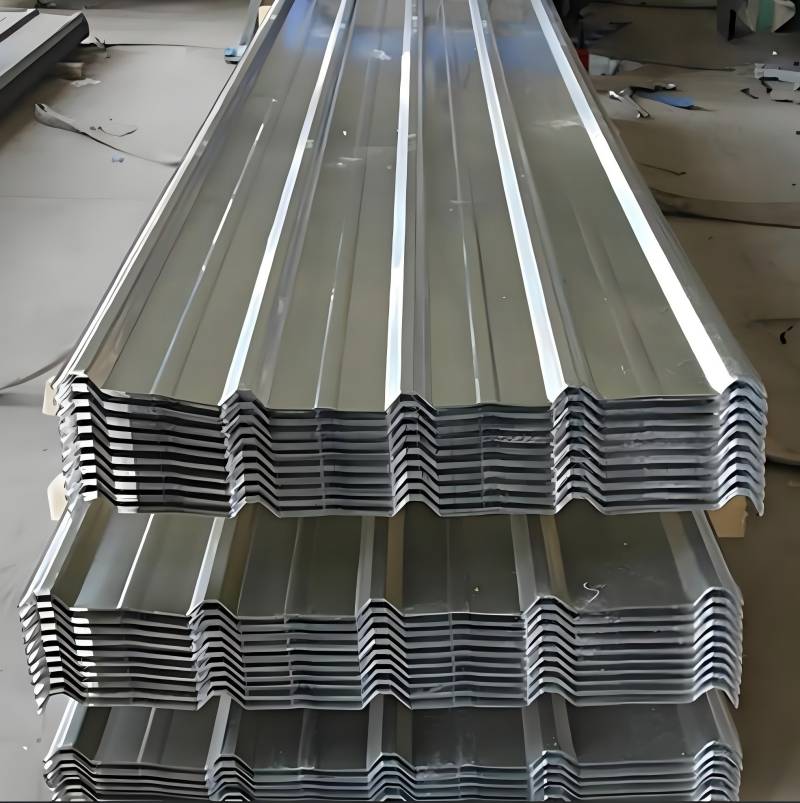

Top 10 Applications of Corrugated Aluminum Sheets in Construction

Corrugated aluminum sheets are versatile materials widely used in the construction industry. Known for their lightweight nature, durability, and corrosion resistance, aluminum sheets offer exceptional strength-to-weight ratios, making them a go-to choice…

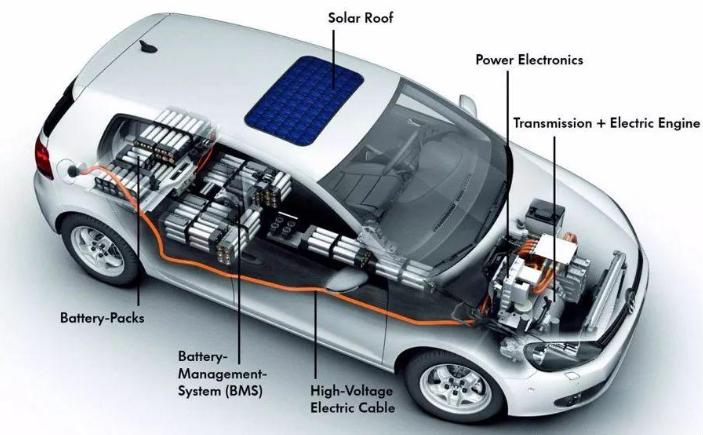

Do Electric Vehicles Have Radiators?

With the increasing popularity of electric vehicles, people are paying more and more attention to the various components of electric vehicles and their working principles. In traditional fuel vehicles, the…