Aluminum vs Stainless Steel in Heat Exchangers: Which is the Better Choice?

Heat exchangers are critical components in various industries, playing a vital role in transferring heat between fluids or surfaces. From automotive and aerospace to chemical processing and HVAC systems, the…

Different Types of Aluminum Louvers for Various Applications

Aluminum louvers have become essential components in modern architecture and industrial systems. Their ability to provide ventilation, sun control, and aesthetic enhancement makes them incredibly versatile. In this article, we’ll explore…

Aluminum Round Tube vs Square Tube: How to Choose

Aluminum tubes come in a variety of shapes, each designed for specific purposes and applications. Round and square aluminum tubes are the most common profiles, but how do you know which one…

Is It Safe to Use Aluminum Foil in Microwave Oven?

Aluminum foil is one of the most versatile materials found in the modern kitchen. Whether it’s wrapping food for storage, covering dishes during baking, or even being used in creative crafts,…

The Versatile Application of 6061 T6 Aluminum Plate in Construction

Aluminum, a lightweight and durable metal, has found widespread application in various industries, including construction. Among the numerous aluminum alloys available, 6061 T6 stands out for its exceptional combination of…

Best Practices for Aluminum Compressed Air Piping Maintenance

Aluminum compressed air piping is commonly used in industrial settings due to its lightweight properties, corrosion resistance, and durability. However, proper maintenance is essential to ensure the system operates efficiently, prolongs…

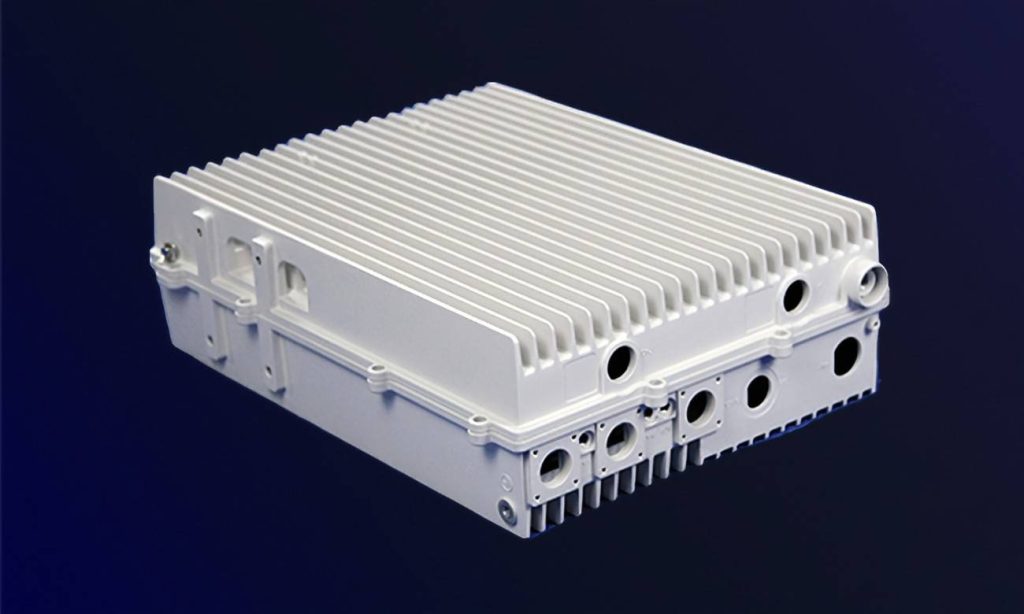

Aluminum Heat Sinks: Material Types and Production Methods

Aluminum heat sinks are pivotal in thermal management across various industries, from consumer electronics to high-performance machinery. The primary function of a heat sink is to dissipate heat generated by electronic…

5356 vs 4043 Aluminum Welding Wire: The Key Differences You Need to Know

When it comes to welding aluminum, the choice of filler metal is crucial to achieving a strong and durable joint. Two of the most common aluminum welding wires are 5356 and 4043. While…

Aluminum Corner Extrusions: The Key to Perfect Angles and Edges

Whether in construction, architecture, or manufacturing, achieving perfect angles and edges is a critical goal. Aluminum corner extrusions offer an effective solution for these requirements, providing clean, seamless connections and enhancing…

7 Common Aluminium Pipe Welding Methods

Aluminium is a lightweight, corrosion-resistant material that has become widely used in various industries, from automotive to aerospace, construction, and even the production of consumer goods. However, aluminium presents unique…

Common Problems and Solutions for Aluminium HFW Pipes Manufacturing

Aluminum High-Frequency Welding (HFW) pipes are widely used in industries such as oil and gas, construction, and automotive due to their lightweight, corrosion resistance, and durability. However, manufacturing these pipes is…

Differences Between Painted and Color Coated Aluminum Coil

Aluminum coils are fundamental materials in many industries, offering a combination of strength, durability, and versatility. Among the various types of aluminum coils, painted aluminum coils and color coated aluminum coils…