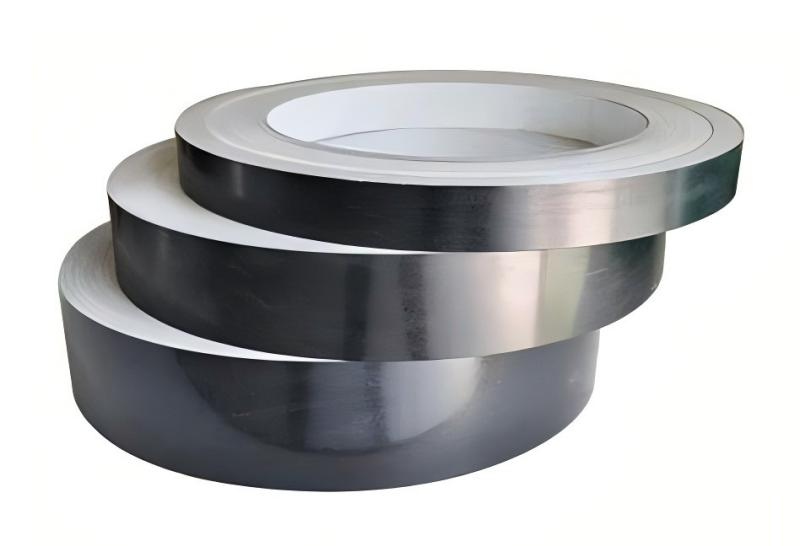

Types and Characteristics of Aluminum Strips

Aluminum strips are widely used across sectors such as construction, automotive, aerospace, and electronics. These strips come in various alloys, shapes, and finishes to suit specific functions and environments. Aluminum…

Understanding Aluminum-Based Products: From Pigment to Paste

Aluminum pigments are among the most valued ingredients in creating metallic effects in a wide range of products. From automotive coatings to decorative packaging, these pigments enhance both visual appeal and…

How to Identify the Quality of Aluminum Profiles?

Aluminum profiles, versatile and durable, are widely used in various industries, from construction and automotive to aerospace and electronics. To ensure optimal performance and longevity of your projects, it’s crucial to…

Avoiding Common Mistakes with Aluminum Filler Metals in Welding

Aluminum welding, widely used in industries like automotive, aerospace, and construction, demands precision and expertise. However, it presents unique challenges compared to other metals, particularly due to its high thermal…

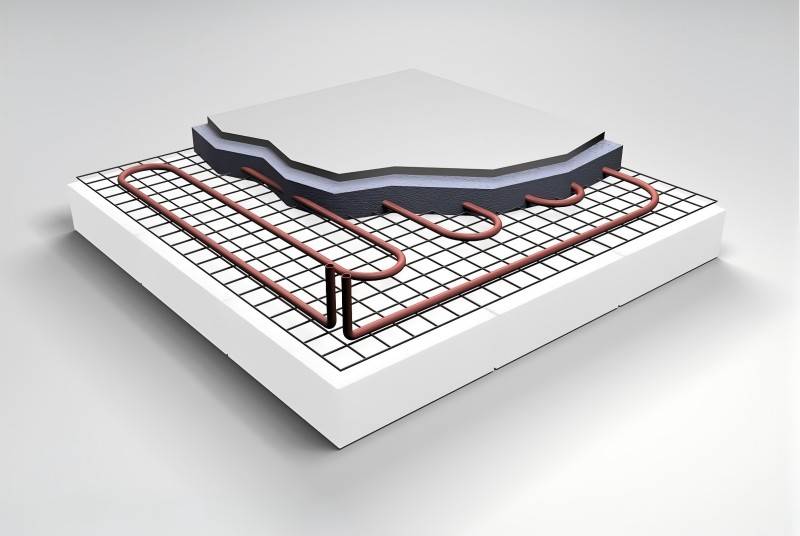

Why Aluminum Plates Are Ideal for Radiant Floor Heating?

Radiant floor heating has become increasingly popular as an efficient and comfortable way to heat homes. This system involves heating a fluid, typically water, and circulating it through tubes embedded…

Medical-Grade Aluminum Alloys: Properties and Applications

Aluminum is one of the most versatile metals used in a variety of industries, and its applications in healthcare have grown significantly in recent years. In the medical field, aluminum…

Aluminum Paste Preparation and Their Uses on Electronics

Aluminum paste, a crucial material in the electronics industry, has garnered significant attention due to its excellent conductivity, heat resistance, and cost-effectiveness. As a versatile conductive material, aluminum paste is…

Aluminum Tube vs. Plastic Tube: Which Is Better for Pharmaceutical Products?

When it comes to pharmaceutical packaging, the choice of material is critical to ensure the safety, efficacy, and longevity of the product. Packaging must protect contents from contamination, preserve quality, and…

How to Install, Maintain, and Repair Aluminium Louvre Windows

Aluminium louvre windows are becoming increasingly popular in modern architecture due to their aesthetic appeal and functionality. They allow for excellent ventilation, offer an unobstructed view, and can enhance the energy…

Small or Large? How Aluminum Wire Size Impacts Performance

In electrical and power transmission applications, aluminum wire is widely used due to its cost-effectiveness, lightweight nature, and reasonable conductivity. However, the performance of aluminum wire isn’t solely dependent on its…

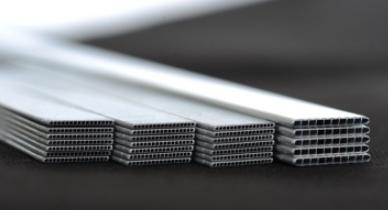

Aluminum Microchannel Tubes: Factors of Heat Exchange Efficiency and its Calculation

Aluminum microchannel tubes are increasingly valued in applications demanding compact, efficient heat exchangers, including HVAC systems, automotive radiators, and electronics cooling. These tubes feature multiple microscopic channels that allow fluids to…

Aluminum Frame for Glass Panel: Where Function Meets Form

Aluminum, known for its strength, durability, and lightweight nature, offers the perfect balance of structural integrity and design flexibility. Aluminum frames have become a popular choice for glass panels due to their…