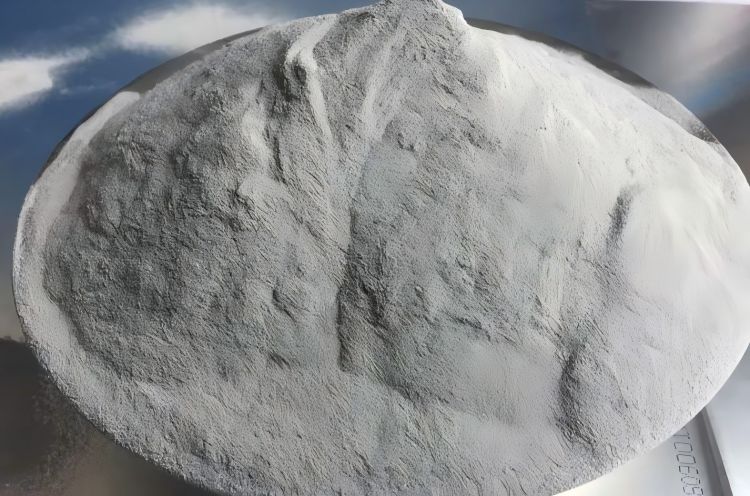

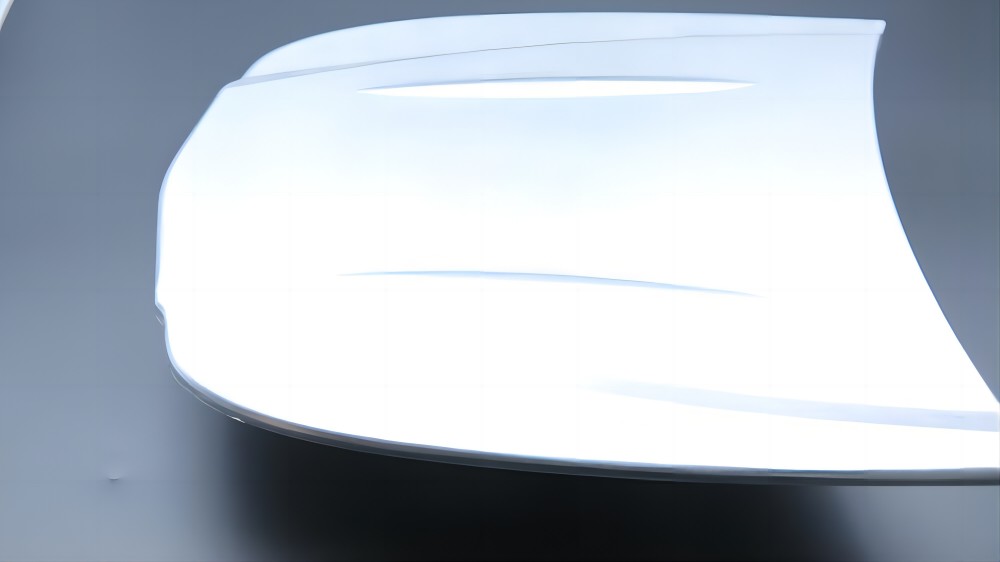

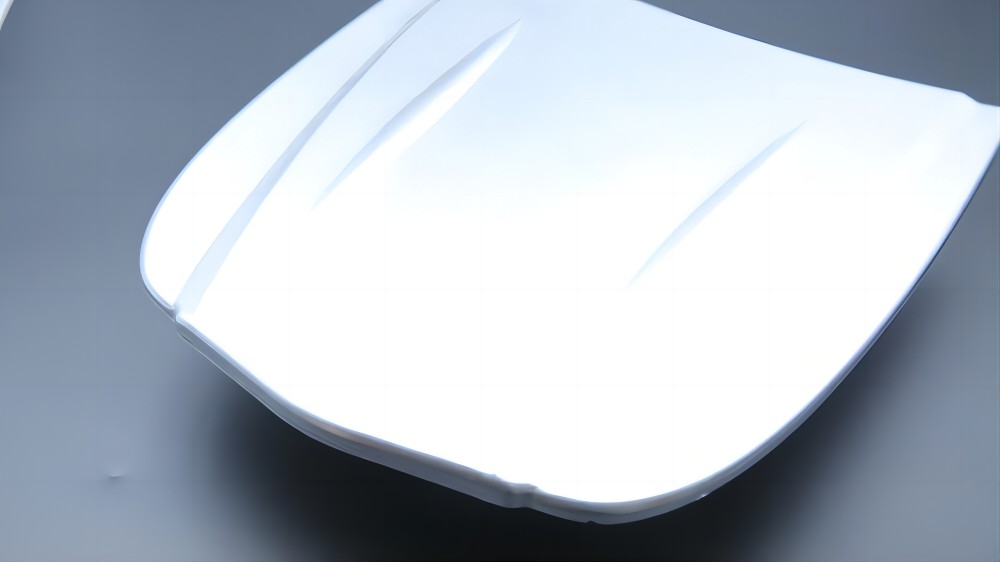

In the realm of automotive customization, achieving a show-stopping metallic finish can elevate your vehicle from ordinary to extraordinary. Among the secret weapons in this pursuit lies aluminum paste, a potent pigment capable of imbuing car bodies with dazzling reflections and mesmerizing depth. However, navigating the diverse landscape of aluminum pastes can be daunting, fraught with considerations that determine the success or failure of your metallic masterpiece. Fear not, intrepid detailers and paint enthusiasts, for this guide delves deep into the technicalities of choosing the perfect aluminum paste for your automotive artistry.

Key Factors to Consider When Choosing Aluminum Paste for Automotive Paint

1. Aluminum Flake Properties

Flake Size

- Large Flakes (15-40 µm): Generate a high degree of light scattering, resulting in bold metallic effects with high brightness and intense color. However, they can lead to increased application thickness, potential settling within the paint, and a more pronounced “flop” effect (significant change in color or intensity from different viewing angles).

- Medium Flakes (5-15 µm): Offer a balance between metallic intensity and application ease. They provide a vibrant metallic sheen with minimal application challenges and less pronounced flop compared to large flakes.

- Small Flakes (1-5 µm): Produce a subtle, pearlescent shimmer with deeper color tones and minimal flop. They are ideal for achieving elegant, understated metallic effects but may not be suitable for applications requiring high brightness.

Flake Shape

- Elongated Flakes: Possess a high aspect ratio, causing significant light scattering and color shift depending on the viewing angle. This results in a pronounced “flop” effect, where the color and intensity of the metallic finish dramatically change as you move around the vehicle.

- Spherical Flakes: Have a more isotropic light scattering profile, leading to smoother, more even metallic coverage with minimal flop. They provide a consistent, mirror-like finish and are preferred for applications where a uniform metallic sheen is desired.

2. Pigment Concentration

- Higher pigment concentration (e.g., 20-30%) delivers a stronger metallic effect with greater light scattering and color saturation. However, it can lead to thicker application, potential drying issues, and increased settling of larger flakes.

- Lower pigment concentration (e.g., 5-10%) results in a less intense metallic effect but offers easier application, faster drying times, and reduced risk of settling. The choice depends on the desired level of metallic intensity and application constraints.

3. Binder Type

- Solvent-Based Binders: Offer excellent durability and compatibility with a wide range of traditional paints, including alkyd and polyurethane systems. However, they typically emit strong solvent fumes, requiring proper ventilation during application and posing potential health hazards.

- Water-Based Binders: These are environmentally friendly and user-friendly, emitting minimal fumes and being easier to clean up. However, they may require specific primers or paints for optimal adhesion and compatibility with certain base coats.

4. Additional Considerations

- Heat Resistance: For applications on components like engine bays or exhaust manifolds, choose heat-resistant aluminum pastes formulated to withstand high temperatures without compromising color or adhesion.

- Chemical Resistance: If the painted surface is likely to encounter fuel spills or harsh cleaning chemicals, select a paste with chemical resistance properties to prevent color fading or degradation.

- UV Protection: Opt for aluminum pastes with built-in UV protection to prevent color fading and ensure long-term color stability, especially for exterior automotive applications exposed to sunlight.

Matching Aluminum Paste to Your Project

1. Desired Finish

- Metallic Intensity: Define the desired level of metallic effect. Do you want a bold, in-your-face chrome-like finish or a subtle, pearlescent shimmer? Large flakes and high pigment concentrations deliver high intensity, while smaller flakes and lower concentrations offer a more subdued effect.

- Color Hue: Aluminum paste acts as a reflective pigment, influencing the final color by interacting with the underlying base coat. Choose a paste with a compatible color profile to achieve the desired hue. For example, a silver paste over a black base coat will result in a cool, dark metallic finish, while a gold paste over a red base coat will produce a warm, fiery metallic effect.

- Flop Effect: Consider the desired level of color shift with the viewing angle. Elongated flakes and high pigment concentrations create a pronounced flop effect, while spherical flakes and lower concentrations minimize it. Determine if a dynamic, shifting color is desired or if a consistent, uniform finish is preferred.

2. Application Type

- Spray Guns: Choose pastes with lower viscosity and good atomization properties for optimal sprayability and even application over large areas. Consider using a dedicated metallic paint thinner for optimal flow and finish.

- Airbrushes: Opt for pastes with slightly higher viscosity for better control and detail work. Experiment with different thinning ratios to achieve the desired flow and coverage for intricate designs and accents.

- Brush Application: Select pastes with a thicker consistency for ease of control and brushwork. This method is suitable for small areas, touch-ups, or achieving textured effects, but may require multiple coats for consistent coverage.

3. Paint Compatibility

- Primer: Ensure the aluminum paste is compatible with your chosen primer. Some primers may contain additives that can affect the adhesion or color of the paste. Consult the technical data sheets of both products for compatibility information and recommended application procedures.

- Topcoat: Choose a topcoat compatible with both the aluminum paste and primer. Consider using a clear coat specifically formulated for metallic finishes to provide additional protection and enhance the brilliance of the metallic effect.

4. Safety and Environmental Concerns

- Volatile Organic Compounds (VOCs): Opt for low-VOC or water-based aluminum pastes to minimize harmful emissions and environmental impact. These options are also generally safer for user health during application, especially in enclosed spaces.

- Personal Protective Equipment (PPE): Regardless of paste type, always wear appropriate PPE, including gloves, respirators, and eye protection, to minimize exposure to chemicals and prevent potential injuries during application.

- Ventilation: Ensure adequate ventilation in your workspace, especially when using solvent-based products. This helps to prevent the buildup of harmful fumes and improve air quality.

Conclusion

Choosing the right aluminum paste is not merely a technical exercise; it’s an artistic endeavor. By understanding the intricate interplay of flake size, shape, binder type, and application method, you can unlock a world of metallic possibilities. So, embrace your inner alchemist, wield the potent power of aluminum paste, and transform your ordinary vehicle into a shimmering, show-stopping masterpiece that reflects your unique automotive vision. Remember, the road to metallic mastery is paved with knowledge, experimentation, and a healthy dose of metallic passion. Now, go forth and unleash your inner dazzle!