In the ever-evolving world of automotive design and manufacturing, achieving the perfect balance between aesthetics and durability is a perpetual pursuit. One innovation that has significantly impacted the automotive industry in recent years is the use of aluminum paste in the enhancement of automotive surfaces. This unassuming yet powerful material has revolutionized the way cars look and perform on the road.

Why it is Shimmering?

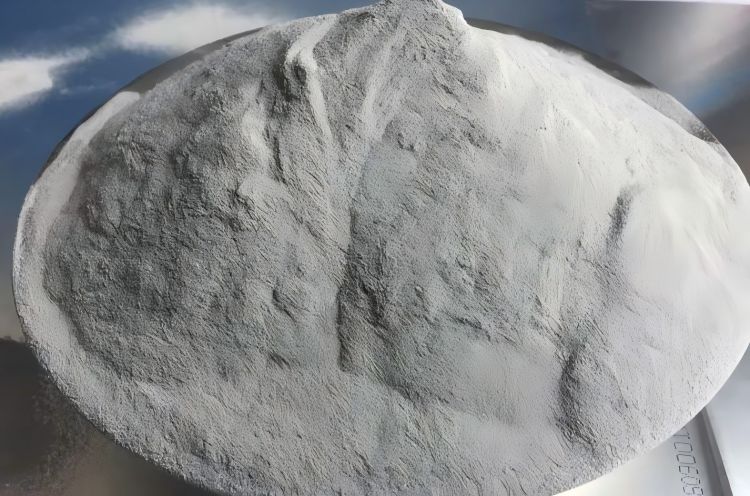

At the heart of the automotive surface enhancement revolution is aluminum paste, a finely powdered form of aluminum that is incorporated into paint formulations. What sets aluminum paste apart is its ability to impart a brilliant metallic finish to the paint, creating a sleek and sophisticated appearance that catches the eye.

Why Use Aluminum Paste in Automotive Surface?

The use of aluminum paste in automotive surface applications offers a range of benefits, contributing to both the aesthetic appeal and functional performance of the vehicle. Here are several reasons why aluminum paste is commonly incorporated into automotive paint formulations:

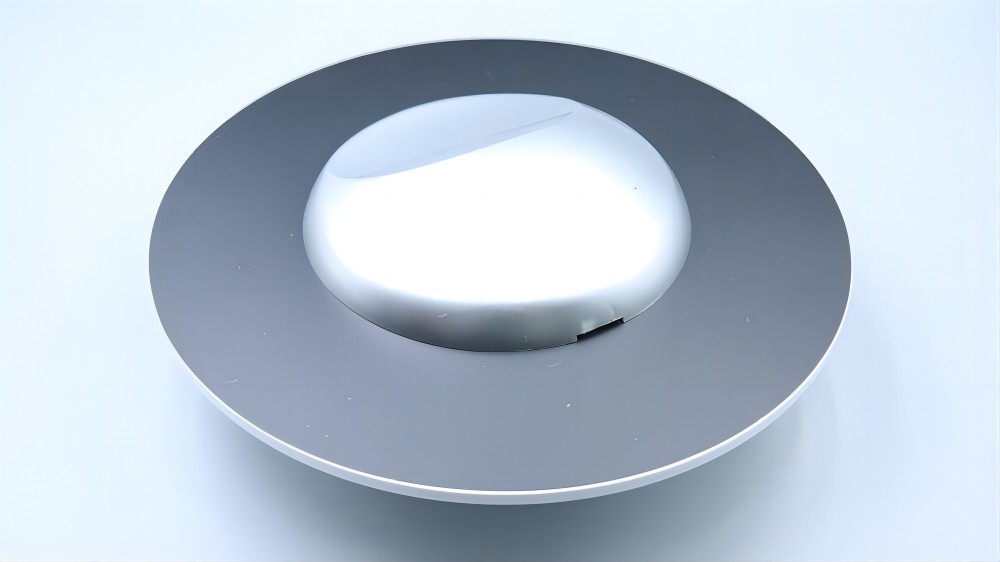

- Metallic Aesthetics: One of the primary reasons for using the aluminum paste is to achieve a metallic finish on the vehicle’s surface. The reflective properties of aluminum particles create a sleek and modern appearance, enhancing the overall visual appeal of the car.

- Dimension and Depth: Aluminum paste adds depth and dimension to the paint, highlighting the contours and lines of the vehicle. This creates a dynamic and visually interesting surface, making the car stand out among others on the road.

- Customization Options: Aluminum paste allows for a wide range of customization options in terms of color and finish. Manufacturers can experiment with different formulations to create unique and eye-catching paint effects, offering consumers a variety of choices to suit their preferences.

- UV Protection: The protective layer formed by aluminum particles in the paint provides effective UV protection. This helps prevent the paint from fading or deteriorating over time due to exposure to sunlight, ensuring that the vehicle retains its vibrant appearance for an extended period.

- Corrosion Resistance: Aluminum is inherently corrosion-resistant. By incorporating aluminum paste into paint formulations, manufacturers enhance the paint’s ability to withstand environmental factors such as rain, snow, and road salt, thereby reducing the risk of rust and corrosion on the vehicle’s surface.

- Durability: Aluminum paste contributes to the overall durability of the automotive paint. The protective barrier formed by the aluminum particles helps shield the underlying layers from scratches, chips, and abrasions, extending the lifespan of the paint job.

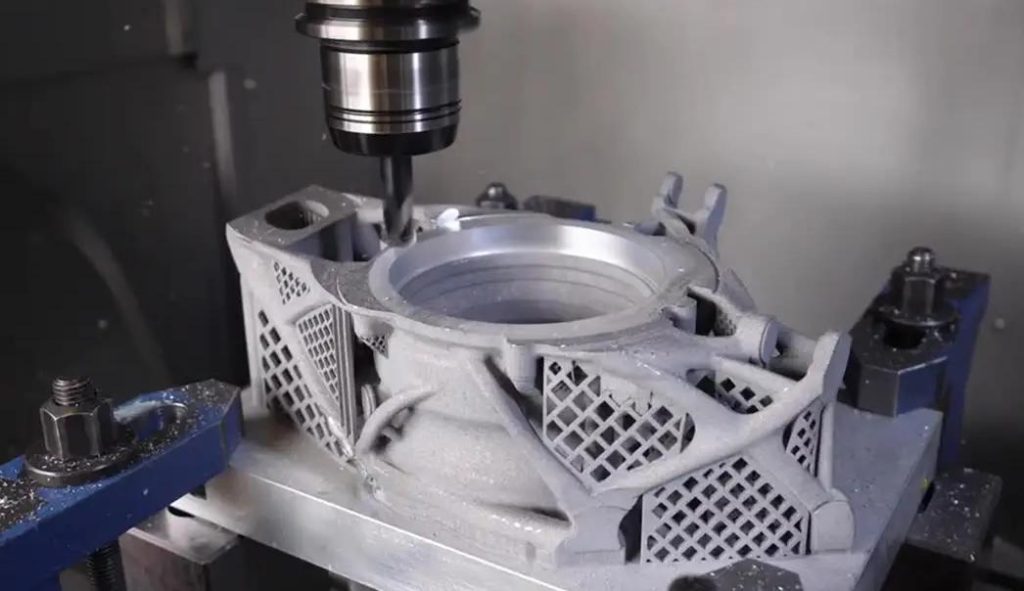

- Technological Advancements: Advances in manufacturing processes enable the precise integration of aluminum particles into paint formulations. This ensures uniform distribution and optimal performance, resulting in a consistent and high-quality finish on each vehicle.

- Lightweight Properties: Aluminum is a lightweight material, and incorporating it into automotive paint does not significantly add to the overall weight of the vehicle. This is especially important in the automotive industry, where reducing weight can contribute to improved fuel efficiency.

- Environmental Sustainability: Aluminum is a recyclable material, and the use of recycled aluminum in paste formulations aligns with environmental sustainability goals in the automotive industry. This helps reduce the environmental impact of manufacturing processes.

- Consumer Expectations: As consumer expectations for visually appealing and durable vehicles continue to rise, automakers seek innovative solutions to meet these demands. Aluminum paste provides a solution that satisfies both the aesthetic preferences of consumers and the durability requirements of modern vehicles.

Conclusion

As we navigate the ever-changing landscape of automotive design, the integration of aluminum paste into paint formulations emerges as a pivotal force. Driven by a relentless pursuit of innovation, manufacturers not only elevate the visual appeal of vehicles but also fortify them against the rigors of daily life on the road. The careful amalgamation of aluminum paste has become a signature move, a stroke of brilliance that adds not only metallic luster but also a layer of protection against the elements.

As we marvel at the sleek finishes and durable exteriors of today’s automobiles, it’s crucial to acknowledge the unsung heroes behind the scenes—the aluminum paste suppliers. Their expertise and commitment to excellence are the driving forces behind the success of this revolutionary enhancement in automotive surface technology. Together with manufacturers, they are charting new territories, proving that the road to automotive excellence is paved with the brilliance of aluminum paste. In the intersection of style, durability, and sustainability, the collaboration between automakers and aluminum paste suppliers stands as a testament to the transformative power of innovation in shaping the future of automotive design.