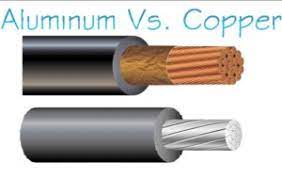

Each metal material has its characteristics. As the most commonly used metals in power systems, copper wire, and aluminum wire have their uses and their advantages, and disadvantages. As an electrician, we must understand the characteristics of these two metal wires, so that they can be used. Only by figuring out the advantages, disadvantages, and characteristics of both of them can we obtain appropriate materials and make the best use of them. Otherwise, it is easy to cause improper use, light line damage, and serious fire.

Comparison of advantages of copper wire and aluminum wire

(1) Low resistivity: The resistivity of aluminum wire cable is about 1.68 times higher than that of copper wire cable.

(2) Good ductility: the ductility of copper alloy is 20~40%, the ductility of electrical copper is more than 30%, and the ductility of aluminum alloy is only 18%.

(3) High strength: the allowable stress at room temperature, copper is 7~28% higher than that of aluminum. Especially the stress at high temperatures, the difference between the two is even greater.

(4) Anti-fatigue: aluminum is easy to break after repeated bending, but copper is not. In terms of elasticity index, copper is also about 1.7~1.8 times higher than that aluminum.

(5) Good stability and corrosion resistance: copper wire is anti-oxidation and corrosion-resistant, while the aluminum wire is easy to be oxidized and corroded.

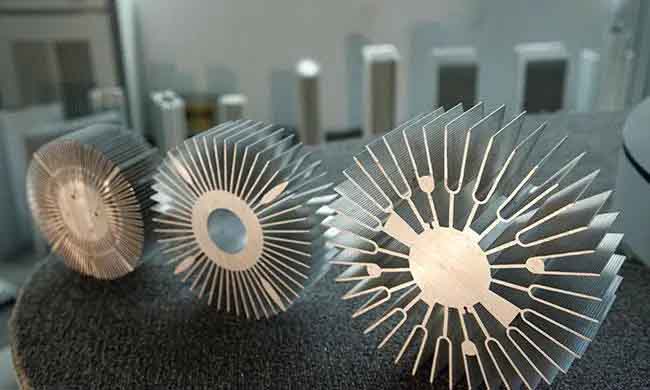

(6) Large current carrying capacity: Due to the low resistivity, the copper wire cable with the same cross-section is about 30%-50% higher than the allowable current carrying capacity (the maximum current that can pass through) of the aluminum wire cable, especially more and more household appliances. , Home improvement basic copper wire.

(7) Aluminum wire is cheaper and more economical.

(8) Aluminum wire and cable is very light, the weight of aluminum wire cable is 40% of that of copper wire cable, and the cost of construction and transportation is low.

(9) Anti-oxidation and corrosion resistance: aluminum reacts with oxygen in the air to quickly form an oxide film, which can prevent further oxidation, so aluminum wire is a must-have material for high-voltage, large-section, long-span overhead power transmission, but it is used for low-voltage lines. These advantages no longer exist.

Disadvantages of aluminum wire

The mechanical strength of the aluminum wire is poor, and the aluminum wire is very easy to oxidizes at the end of the connecting wire. After the end of the connecting wire is oxidized, the temperature will rise and the contact will be poor, which is a frequent point of failure (power failure or disconnection).

Aluminum wire has low electrical conductivity, large electrical loss, poor tensile strength, and low corrosion resistance, and joint parts are particularly prone to oxidation.

Disadvantages of copper wire

The high price of copper wire and the large proportion of copper wire determines the high cost of copper wire. There are many performance advantages as a cable, but the cost is high! Therefore, our common overhead wires do not use copper wires. It is good or too heavy, so overhead wires often use more aluminum wires, and copper wires are usually used for ground wires.

Can copper wire and aluminum wire be directly connected?

The chemical and physical properties of copper and aluminum are very different and should not be directly connected. When the connection is required, copper-aluminum transition clips, copper-aluminum transition joints, copper wire tinning, or aluminum wire lining are generally used for direct connection.

Because the electrochemical properties of copper and aluminum are different. A chemical battery is formed when it encounters an electrolyte formed by water, carbon dioxide, and other impurities.

This is because aluminum is easy to lose electrons to become a negative electrode, and copper is difficult to lose electrons to become a positive electrode, so an electromotive force of 1.69V is formed between the positive and negative electrodes, and a small current passes through, corroding the aluminum wire, the so-called electrochemical corrosion. This will cause poor contact between copper and aluminum and increase the contact resistance.

When a current passes through, the temperature of the joint will increase, and the temperature will increase and accelerate the corrosion of the joint, increase the contact resistance, and cause a vicious circle until it burns out and even causes a fire.

Summarize

Each metal material has its characteristics, copper wire and aluminum wire have their advantages and disadvantages, and their fields of use are also different. However, when using wires in family life, copper wires have obvious advantages over aluminum wires. Therefore, it is the correct choice to understand the characteristics of metal wires, adjust measures to local conditions, use appropriate materials, and make the best use of them.