Urbanisation, new infrastructure, and further advances in coating technology galvanise global markets and heighten consumer interest in versatile, durable, and lightweight materials. The global market for color coated aluminium coils is projected to grow significantly as the lightweight and durable aluminium product is adaptable to construction, decorative, home appliance, transportation, and other industries. Because of the anticipated long-term growth across numerous industries, many are now investing in aluminium coils over competitors. Industry analytics currently forecast the coil coating market to grow from $46-47 billion in 2024 to upwards of $55-70 billion by 2030-2033. As the market expands, coated aluminium coils will be the top choice to withstand corrosion, appear aesthetically pleasing, and last significantly longer than competitors.

Global Market Size and Growth Outlook

On a regional level, demand for coil-coated aluminium is greater in Asia-Pacific, the Middle East, and Europe. Asia-Pacific, led by China, is also the largest producer and exporter of coil aluminium. The region is characterised by significant ongoing construction, rapid urbanisation, and an increasing emphasis on green materials, which are a combination of the primary drivers for growth in the region.

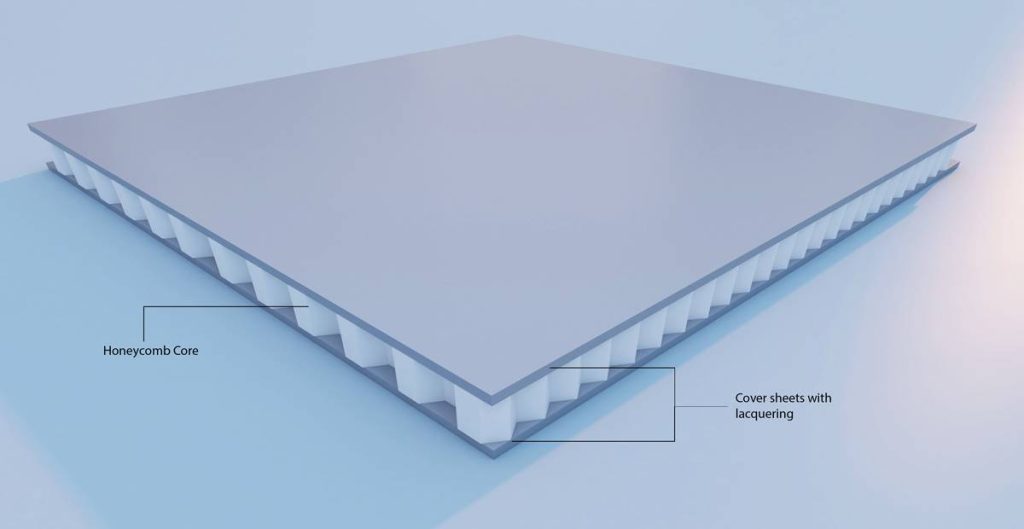

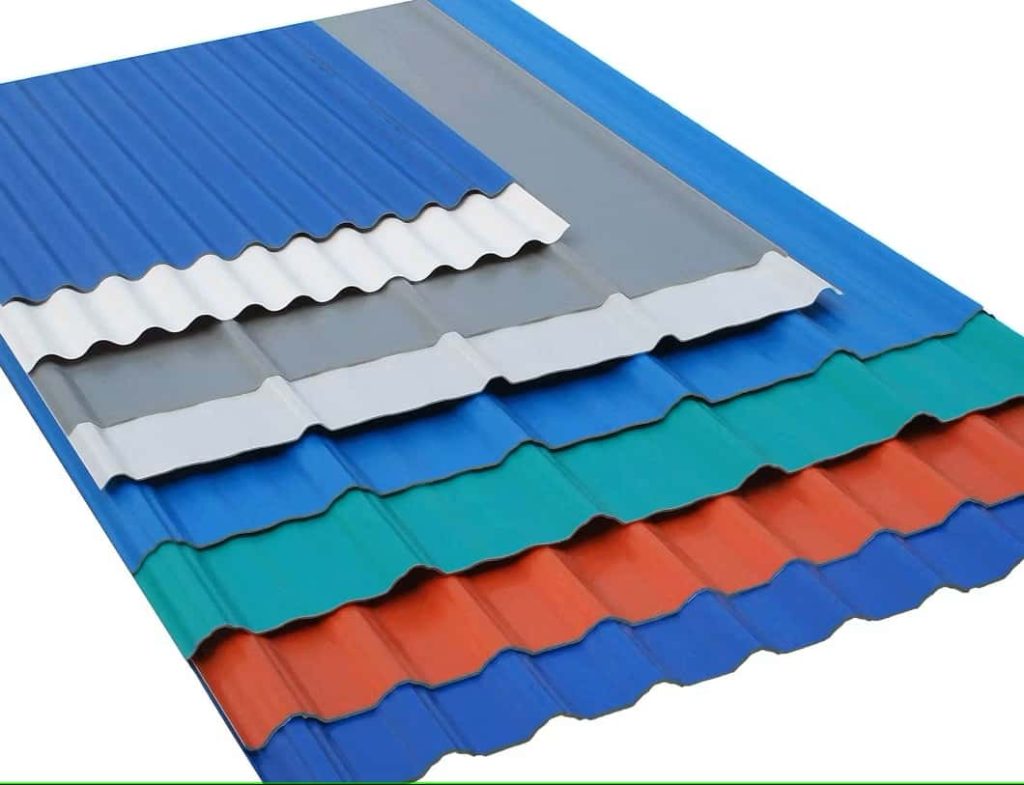

From a global perspective, there is a shift in the market from the use of galvanised steel panels, which are the traditional materials in construction, to aluminium, which has a better density, higher corrosion resistance, a longer service life, and a lighter weight. This shift is most prominent in large facade systems and roofing panels, the manufacturing of composite panels, and there are external applications in architectural design. For this reason, there have been numerous significant searches in the 2025 global coil coatings market forecast, which has led to numerous queries for alloy 1100, 3003, 5005 coated aluminium coil suppliers in China, especially in the last year.

Why Color Coated Aluminum Coil Is Gaining Market Share?

1. Material and Performance Advantages

Color-coated aluminium coils can be very beneficial compared to other materials. Aluminium is very lightweight and eco-conscious as it can be maintained and processed easily. In modern architecture, aluminium is highly sought after compared to other metals. Aluminium is very resistant to corrosion, and with the addition of PE or PVDF coated systems, the lifespan of the aluminium roofing, façade, and cladding installations can be extremely long.

Technical researchers increasingly publish color-coated aluminum coil corrosion resistance test data demonstrating long-term stability even in coastal or industrial environments. With PVDF and FEVE coatings, the surface can maintain color gloss for over 20–30 years, far exceeding standard enamel coatings.

2. Technological Improvements in Coating Formulations

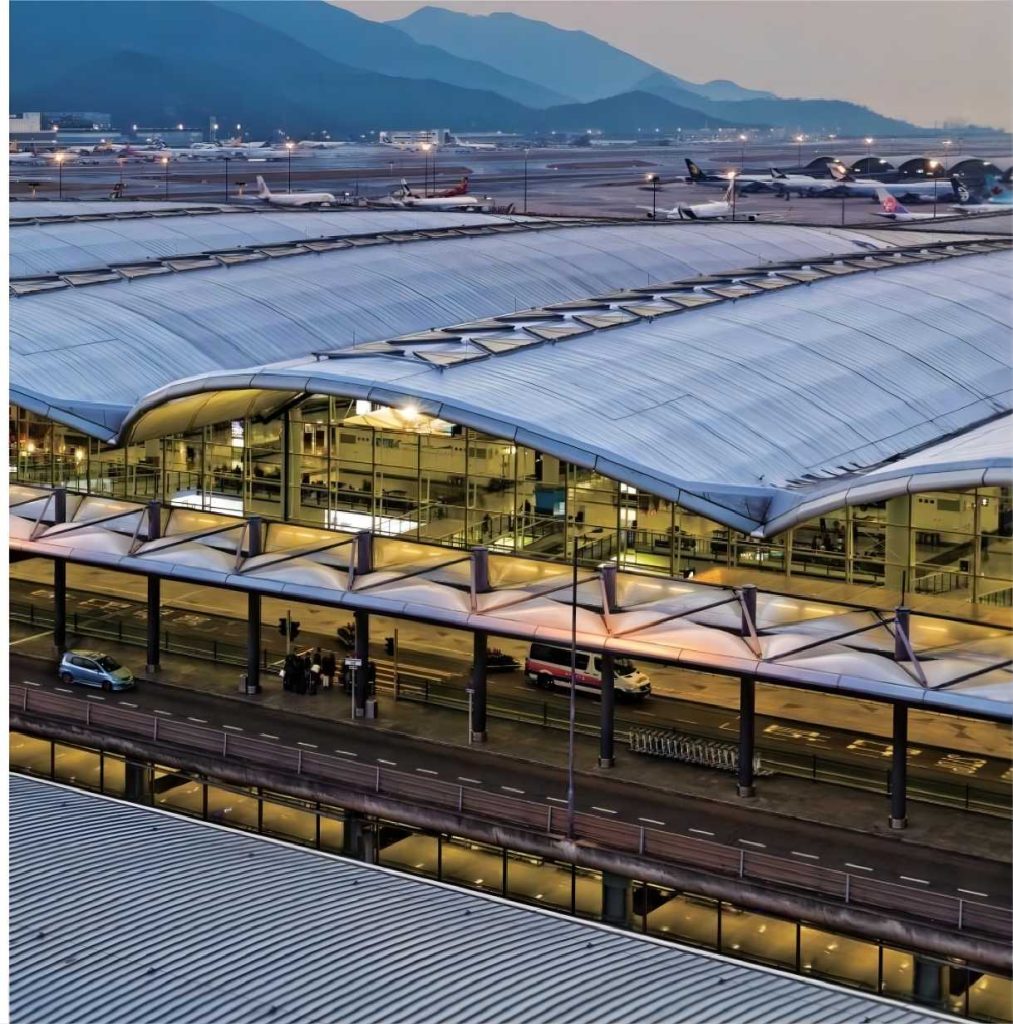

Technological advancements provide the ability to coat aluminium in many different colours. Coatings such as PVDF and FEVE are the best in the protection of UV rays, are highly weather resistant, and do not allow pollution to settle in the coating. This makes them the best in high-value projects like airports, high-rise buildings, and coastal structures.

Customized PE coatings—often seen in color-coated aluminum coil PE coating 0.25 mm 3003 alloy models—are widely used for general construction, interior panels, and appliance manufacturing.

Applications in Different Industries

1. Building Facades and Exterior Cladding

One of the biggest growing segments is architectural cladding. With strict performance requirements in colour retention, durability, and resistance to corrosive environments, ethnic developers have PVDF colour coated aluminium coil for building facades. High-rise commercial towers, stadiums, and cultural centres, as well as transportation hubs, all use coated aluminium panels for construction as the primary material.

2. Interior Decoration and Aesthetics

Due to its virtually unlimited options with designs, coated aluminium coil is being sought after more and more each day by architects and designers alike. Differently designed surface finishes, such as wood grain paint finish colour coated aluminium coil, marble texture, embossed, and brushed metallic styles, provide one of a kind visuals on interior structure designs like ceilings, wall panels, and more. Because of the increasing popularity of customised interior design, this segment of coated aluminium is predicted to keep growing at a steady rate.

3. Transportation and Automotive Lightweighting

To increase fuel efficiency, we need to find ways to reduce weight. Coated aluminium panels are used for the body and for the exterior and interior trim of trailers and caravans. For long-haul transportation equipment, the corrosion resistance and smooth, attractive appearance of aluminium coils are great to work with.

4. Home Appliances and Consumer Goods

All other home appliance industries also have large market shrinks. For example, the side panels of refrigerators, the outer shells of washing machines, and components of HVAC systems are obtaining more and more colour coated aluminium as a result of its long-lasting character, corrosion resistance, and sleek appearance.

Rise of Customization and Small-Batch Production

Project-based customization has become a defining trend. End-users increasingly request custom RAL color-coated aluminum coil sheet with a width of 1500 mm, flexible minimum order quantities, and specialized surface textures. Color-coated aluminum coil manufacturers in China and Southeast Asia now offer small-batch production options, such as color-coated aluminum coil minimum order quantity of 500 kg, which helps project contractors reduce waste and cost.

Customization includes:

- Alloy selection (1100 / 3003 / 5005 / 5052)

- Width (600 mm–1500 mm)

- Thickness (0.15–1.5 mm)

- Coating system (PE, PVDF, FEVE)

- Custom RAL / Pantone colors

Cost, Supply Chain, and Competitive Landscape

Even though aluminium costs more than steel at the beginning, the savings over time due to lower upkeep, better ability to handle harsh weather, and a longer life span make it more cost-effective over the life cycle of the building, really the exterior finishing.

China is the world leader in the manufacturing of colour coated aluminium coil for the construction of buildings because of its immense production abilities, state of the art coating lines, and low prices. The availability of raw materials, energy costs, and the price of chemicals for coating are important for balancing the world supply chain.

Sustainability and Environmental Drivers

We are receiving an increasing number of requests for aluminium components due to the ESG-focused demand for recycled materials. Because of aluminium’s long life span in service, global sustainability trends, and 100% recyclability, there’s a growing number of environmentally focused searches like “sustainable building materials aluminium coil recyclable.”

PVDF and FEVE coatings further decrease the environmental impact of building operations by minimising maintenance needs, cleaning frequency, and chemical application.

Future Opportunities and Emerging Trends

Looking ahead to 2025–2030, new market opportunities will be driven by:

- Growth of modular and prefabricated construction

- Development of self-cleaning, anti-graffiti, and anti-corrosion nano-coatings

- Rising use of aluminum in renewable energy facilities

- Increased adoption of aesthetic architectural materials with custom designs

- Higher global demand for ultra-durable PVDF and FEVE coatings

The global colour coated aluminium coil market is growing due to industrial expansion, advanced coating technology, and increasing sustainability needs. Bringing these trends together and considering the strong customisation that aluminium coil products offer, their durability, the evolving architectural aesthetics, and the market’s growing positivity, it is extremely likely that aluminium coil products will hold an even greater market size in the coming years.