What is Aluminum Alloy?

Aluminum alloy is made of pure aluminum by adding some alloying elements, such as aluminum manganese alloy, aluminum copper alloy, aluminum-copper-magnesium series hard aluminum alloy, aluminum-zinc-magnesium-copper series super-hard aluminum alloy, which can be made into aluminum plates, aluminum coils, aluminum profiles, etc. Aluminum alloy has better physical and mechanical properties than pure aluminum: easy processing, high durability, wide application range, good decorative effect, and rich colors. Aluminum alloys are divided into anti-rust aluminum, hard aluminum, super hard aluminum, and other types, each type has its scope of use and its code for users to choose from.

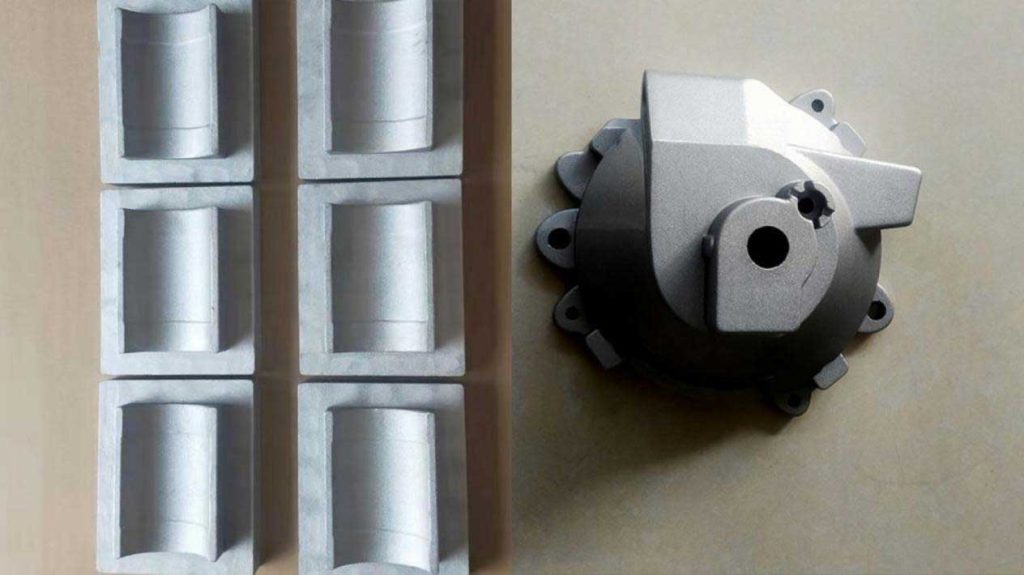

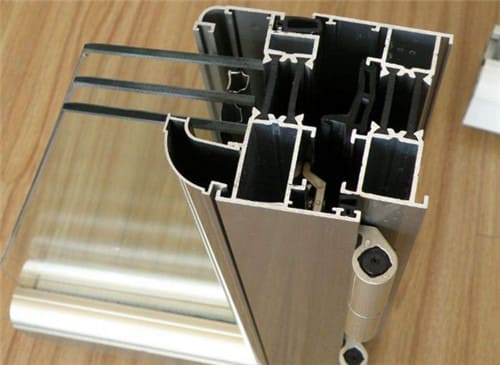

Aluminum alloy still maintains the characteristics of being lightweight, but the mechanical properties are significantly improved. The application of aluminum alloy materials has the following three aspects: one is as a force-bearing member; the other is as a door, window, pipe, cover, shell, and other materials; the third is as a decorative and thermal insulation material. Using the characteristics of aluminum alloy that can be colored after anodizing treatment, it can be made into various decorations. The surface of aluminum alloy sheets and profiles can be processed for anti-corrosion, embossing, painting, printing, and other secondary processing.

What is Titanium Alloy?

Alloys based on titanium and other alloying elements are called titanium alloys. Titanium alloy has the advantages of low density, high specific strength, good corrosion resistance, and good process performance, and it is an ideal aerospace engineering structural material.

When cutting titanium alloys, the deformation coefficient will be less than or equal to one. The friction on the surface during cutting is relatively large, resulting in faster furniture wear. The temperature of titanium alloy cutting is also relatively high. Due to the relatively small thermal conductivity of titanium alloy, the heat generated during processing is not easily transmitted. In general, the heat generated by titanium alloy processing is about twice as high as that of stainless steel.

The chilling phenomenon caused by titanium alloy processing is more serious. The chemical activity of titanium alloy is relatively large. When cut at high temperatures, it is easy to absorb oxygen and nitrogen to produce hard outer skin. In addition, during cutting, changes in plasticity also lead to surface hardening. This will not only lead to fatigue strength of the parts but also accelerate the wear of the props.

Differences between Titanium Alloy and Aluminum Alloy

1. Difference in color

Titanium alloy is a silver-white metal, and its performance is also relatively good. Aluminum alloy is a non-ferrous metal with good strength and strong moldability.

2. Difference in Performance

The density of titanium alloy is 4.54 grams per cubic centimeter, which is lighter than steel, heavier than magnesium, and has better high-temperature resistance. The density of aluminum alloy will be smaller, only 1/3 of iron, and it has a low melting point, high moldability, and easy processing.

3. Difference in Usage

Titanium alloys can carry more weight when used to make aircraft and can also be used to make submarines, which are less susceptible to corrosion and can dive deeper. Aluminum alloys are commonly used in aluminum alloy doors and windows and have also been widely used in aerospace and machinery.

How to Distinguish Between Aluminum Alloy and Titanium Alloy?

1. If you have two materials on hand, one is aluminum, and the other is titanium alloy, as long as the two materials are drawn on each other. The scratched one is aluminum. Because titanium is harder than aluminum.

2. Compared with acid resistance, aluminum reacts immediately with acid, and titanium has good acid resistance.

3. Aluminum doors of the same size are the lightest, titanium doors are slightly heavier, and steel doors are the heaviest. But if the manufacturer deliberately deceives people, it is possible to make a door as heavy as titanium alloy by mixing aluminum and steel. It’s easy to tell if there’s steel in the door, though. Take a magnet to see if it will attract to the door. Titanium alloys are not magnetic and will not attract magnets.

4. Find a small, inconspicuous corner and sand off a layer of an oxide film or paint to expose the metal underneath fully. Then take a closer look at the color of the metal. Take an empty Coke can (aluminum), sand off the paint on the surface, and compare it to the door. Aluminum alloys are light gray, and titanium alloys are dark gray and look glossier than aluminum.

5. If possible, you can also measure resistance. The resistance of titanium alloy is much larger than that of aluminum alloy.