Aluminum paste, a seemingly simple material, holds a surprising depth when it comes to its applications and variations. Far from being a uniform substance, aluminum paste exists in distinct forms, each tailored for specific purposes. This article delves into the world of aluminum paste, exploring the core types, their properties, and the diverse applications they enable.

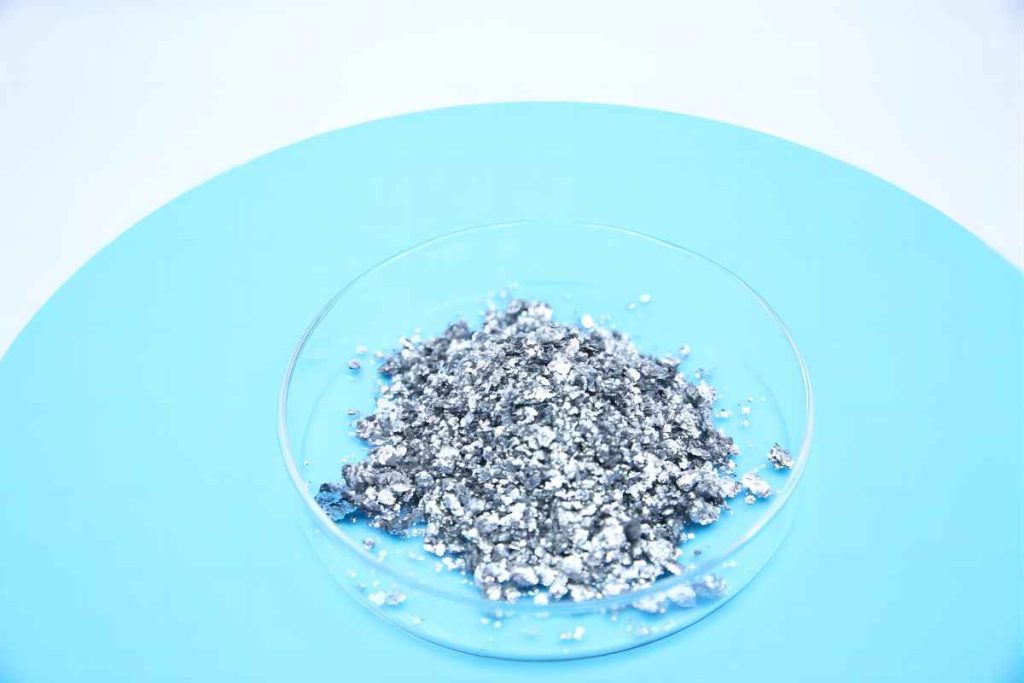

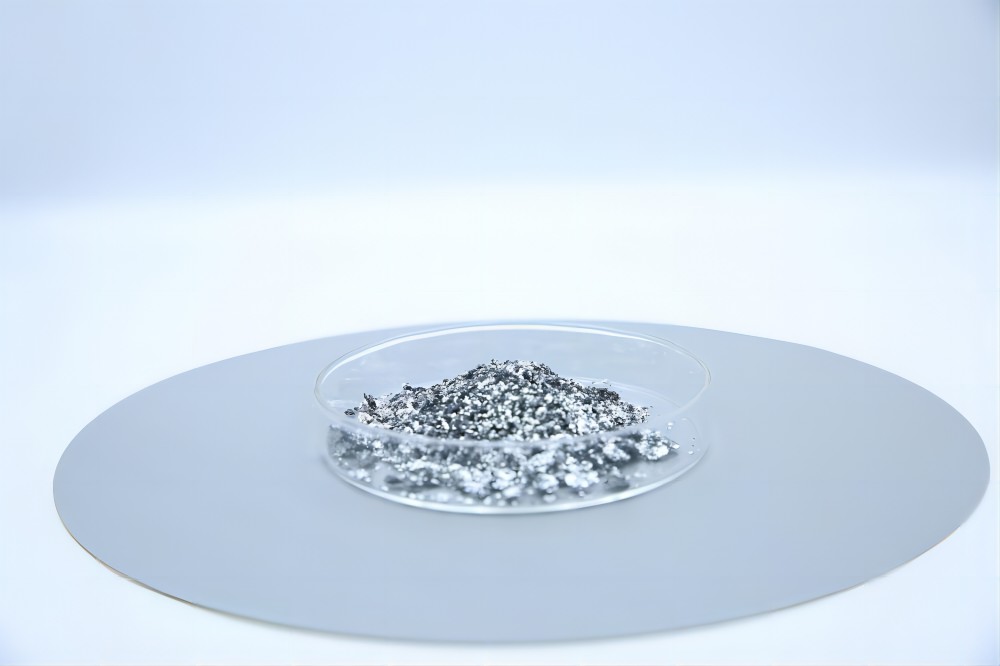

What is Aluminum Paste?

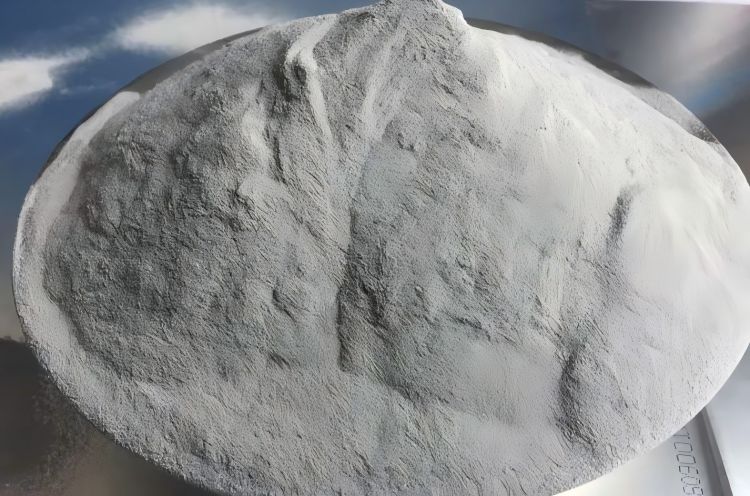

At its foundation, aluminum paste consists of microscopic aluminum flakes suspended within a carrier medium. This carrier can be organic-solvent based or aqueous, depending on the desired properties and end use. The size, shape, and orientation of the aluminum flakes within the paste significantly impact its visual effect and functionality.

Aluminum paste finds application across a wide range of industries. It imparts a metallic sheen to paints, inks, and coatings, making it a vital component in creating visually appealing and functional finishes for automobiles, signage, and decorative elements. Beyond aesthetics, aluminum paste offers practical benefits in various industrial settings. It serves as a component in heat sinks for electronic devices, owing to its ability to dissipate heat effectively. Additionally, aluminum paste plays a role in specific explosives and pyrotechnics due to its unique properties.

Common Two Types of Aluminum Paste: Leafing vs. Non-Leafing Aluminum Paste

Within the realm of aluminum paste, two primary categories reign supreme: leafing and non-leafing. Understanding the distinction between these types is crucial for selecting the appropriate paste for a particular application.

A. Leafing Aluminum Paste

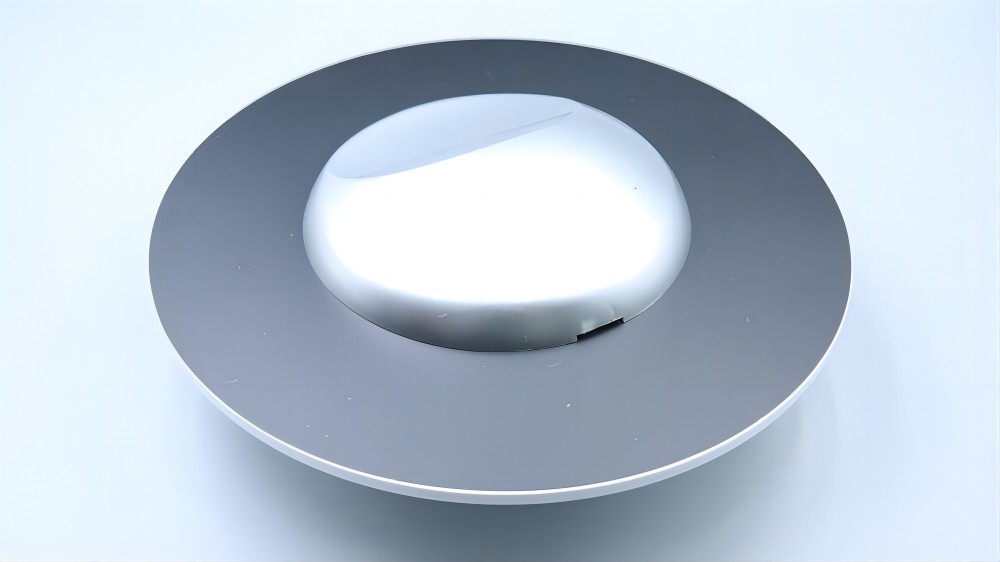

Leafing aluminum paste boasts a characteristic feature – meticulously aligned aluminum flakes. These flakes are not randomly dispersed within the carrier but rather meticulously arranged in a parallel fashion. This specific orientation allows the flakes to overlap efficiently when applied, maximizing light reflection. The consequence? A dazzling, metallic finish that elevates the visual appeal of various products.

Properties of Leafing Aluminum Paste

- High reflectivity: The aligned flakes create a mirror-like effect, resulting in a pronounced metallic sheen.

- Excellent hiding power: The overlapping flakes effectively obscure the underlying surface, requiring less paste to achieve a solid metallic finish.

- Smooth finish: The parallel arrangement of flakes contributes to a visually smooth and even appearance.

Applications of Leafing Aluminum Paste

- Automotive paints: Leafing aluminum paste is a key ingredient in high-end automotive paints, delivering a sleek and luxurious metallic finish to car exteriors.

- Signage and displays: Signage and displays that demand a high-impact visual presence often utilize leafing aluminum paste to create eye-catching metallic lettering and graphics.

- Foil stamping: The ability of leafing aluminum paste to transfer a metallic effect onto various substrates makes it ideal for foil stamping, a technique used in decorative printing and packaging.

B. Non-Leafing Aluminum Paste

Non-leafing aluminum paste stands in contrast to its leafing counterpart. Here, the aluminum flakes are not meticulously aligned but rather randomly distributed throughout the carrier medium. This random dispersion has a significant impact on the visual outcome. Light reflection becomes less efficient, resulting in a subdued, matte finish compared to the high shine of leafing paste.

Properties of Non-Leafing Aluminum Paste

- Lower reflectivity: Due to the random flake orientation, light scatters instead of reflecting intensely, leading to a muted metallic effect.

- Lower hiding power: The non-overlapping flakes offer less coverage, potentially requiring more paste to achieve a uniform appearance.

- Textured finish: The random distribution of flakes can impart a slight texture to the final product.

Applications of Non-Leafing Aluminum Paste

- Industrial applications: Non-leafing aluminum paste plays a vital role in various industrial applications where aesthetics are less crucial than functionality. Its presence in heat sinks facilitates efficient heat dissipation in electronic devices.

- Explosives and pyrotechnics: Specific types of explosives and pyrotechnics utilize non-leafing aluminum paste for its unique properties relevant to their controlled combustion.

- Paints and coatings: While less prominent for achieving a high-shine metallic finish, non-leafing aluminum paste finds use in specific paints and coatings where properties like corrosion resistance or UV protection are desired.

Other Special Types of Aluminum Paste

While leafing and non-leafing aluminum pastes represent the foundation, the world of aluminum paste offers a wider range of options tailored for specific applications. These specialty pastes achieve unique visual or functional effects by manipulating the size, shape, or properties of the aluminum flakes within the carrier medium.

1. Fine Aluminum Paste: Fine aluminum paste stands out for its exceptionally small aluminum flakes. These flakes have a diameter significantly smaller compared to standard aluminum paste. The reduced size translates directly into the visual outcome. When applied, the closely packed, minuscule flakes create a remarkably smooth and even metallic finish. This characteristic makes fine aluminum paste ideal for applications where a flawless, high-quality metallic appearance is desired.

2. Sparkling Aluminum Paste: Sparkling aluminum paste takes visual appeal to a new level. Unlike standard aluminum paste, the flakes in this variety undergo a specialized treatment process. This treatment alters the surface characteristics of the flakes in a precise manner. The result? The treated flakes exhibit a unique light-scattering property. When incorporated into a product, sparkling aluminum paste imparts a shimmering or glittering effect to the final surface. This captivating visual characteristic adds a touch of glamour and intrigue, making it a popular choice for decorative applications.

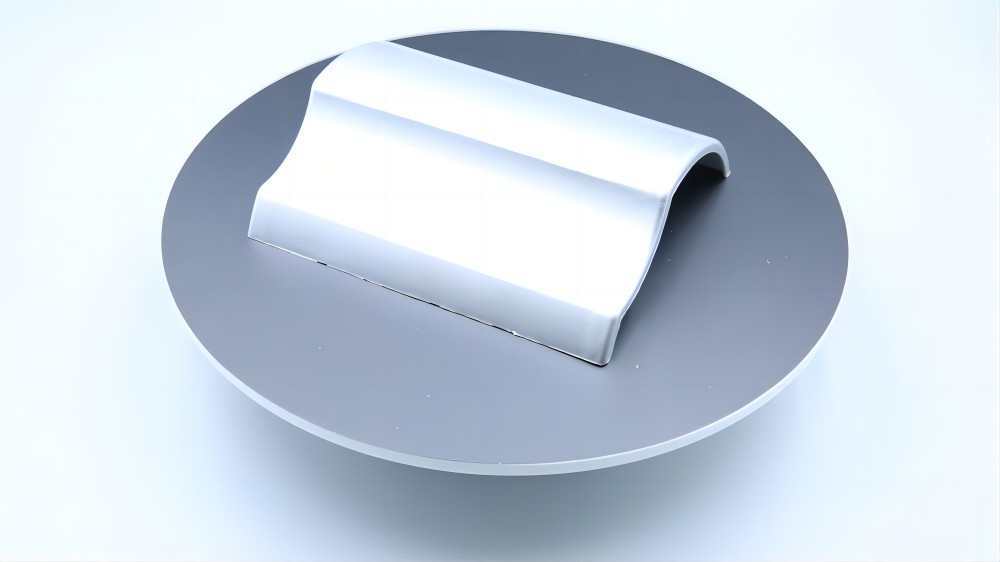

3. Coarse Aluminum Paste: Coarse aluminum paste presents a stark contrast to its fine counterpart. Here, the aluminum flakes have a considerably larger diameter compared to standard aluminum paste. This deliberate size difference plays a crucial role in the final aesthetic. The larger flakes are less likely to pack tightly together when applied, resulting in a distinct textured finish. This textured appearance exudes an industrial or rustic aesthetic, making coarse aluminum paste a suitable choice for products seeking a more raw or aged look.

4. Waterborne Aluminum Paste (known as water based aluminium paste): Environmental consciousness has become a significant driving force in various industries. The development of waterborne aluminum pastes directly addresses this growing concern. These pastes are formulated specifically for use in water-based paints and coatings. This eliminates the need for organic solvents, which are often volatile organic compounds (VOCs) that contribute to air pollution. By opting for waterborne aluminum paste, manufacturers can create eco-friendly products that adhere to stricter environmental regulations.

Conclusion

The realm of aluminum paste offers a spectrum of possibilities. From the dazzling shine of leafing paste to the functional properties of non-leafing varieties, each type caters to specific needs. Specialty pastes further expand the options, offering fine, sparkling, or coarse textures, along with water-based alternatives. This versatility ensures that aluminum paste remains a valuable material across diverse industries, from automotive and signage to industrial applications and eco-conscious endeavors.