In the realm of creative expression and industrial innovation, few materials boast the captivating versatility of leafing aluminum paste. This unassuming concoction, composed of microscopic aluminum flakes suspended in a carrier, possesses the power to transform surfaces, imbuing them with dazzling metallic finishes and remarkable functionality. Delving into its essence, we uncover a treasure trove of applications, each unveiling a facet of its brilliance.

Unmasking the Magic: Composition and Properties

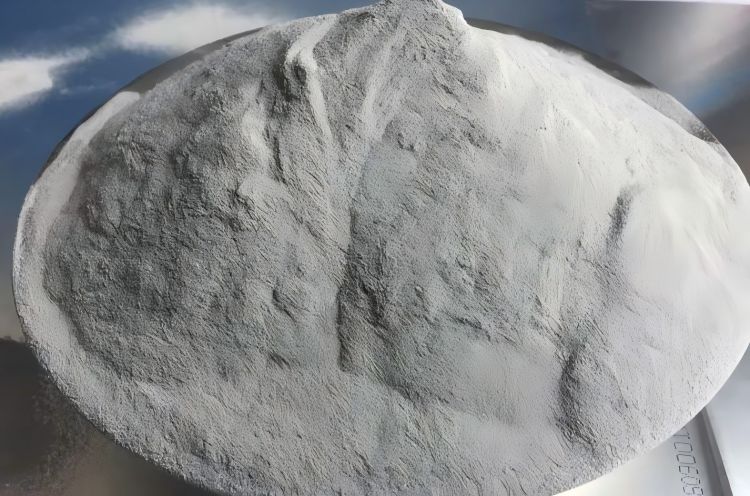

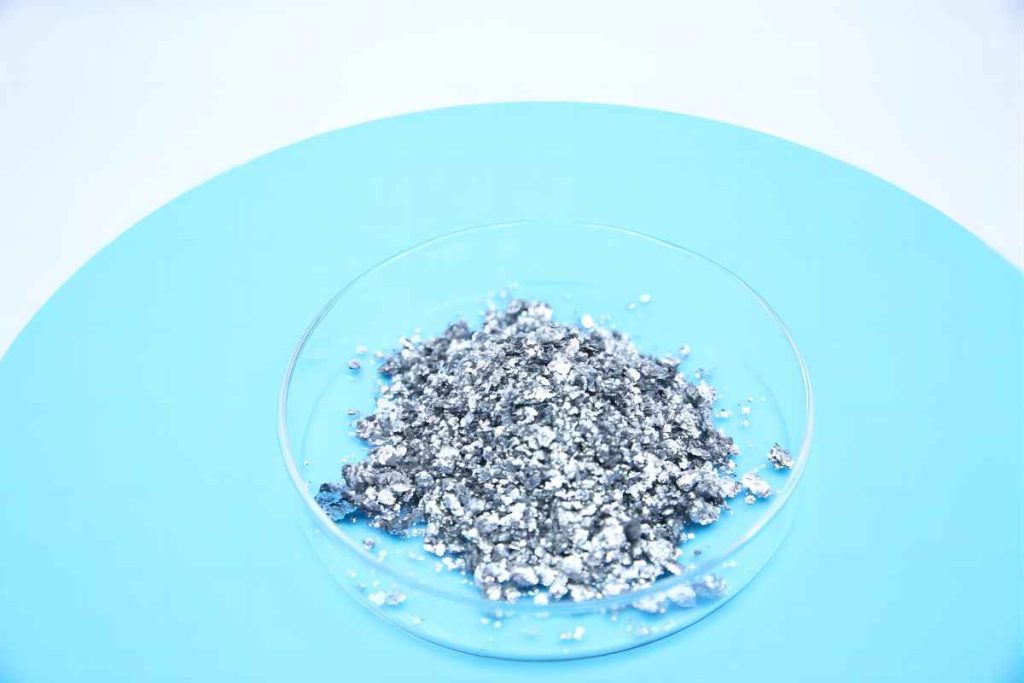

At the heart of leafing aluminum paste lies a captivating dance between science and artistry. The magic begins with the aluminum flakes, minute slivers of the element renowned for their exceptional light-reflecting abilities. These miniscule marvels, measuring mere micrometers in thickness, hold the key to the paste’s transformative power. Coated with a special stearic acid treatment, they acquire a hydrophobic and oleophobic nature, gracefully repelling both water and oil. This seemingly insignificant characteristic becomes the catalyst for the breathtaking leafing effect, allowing the flakes to float and align themselves on the surface of a liquid, creating a mirror-like expanse of metallic splendor.

But the flakes alone wouldn’t paint the full picture. They require a stage, a medium to carry them and facilitate their artistic expression. This role is fulfilled by the carrier, typically a solvent or oil, carefully chosen to complement the flakes and the intended application. Water-based carriers, for instance, offer environmental advantages and ease of cleanup, while oil-based options often provide superior durability and adhesion. The interplay between the flakes and the carrier dictates the paste’s viscosity, influencing its application methods and the final finish.

A Canvas of Possibilities: Applications Across Industries

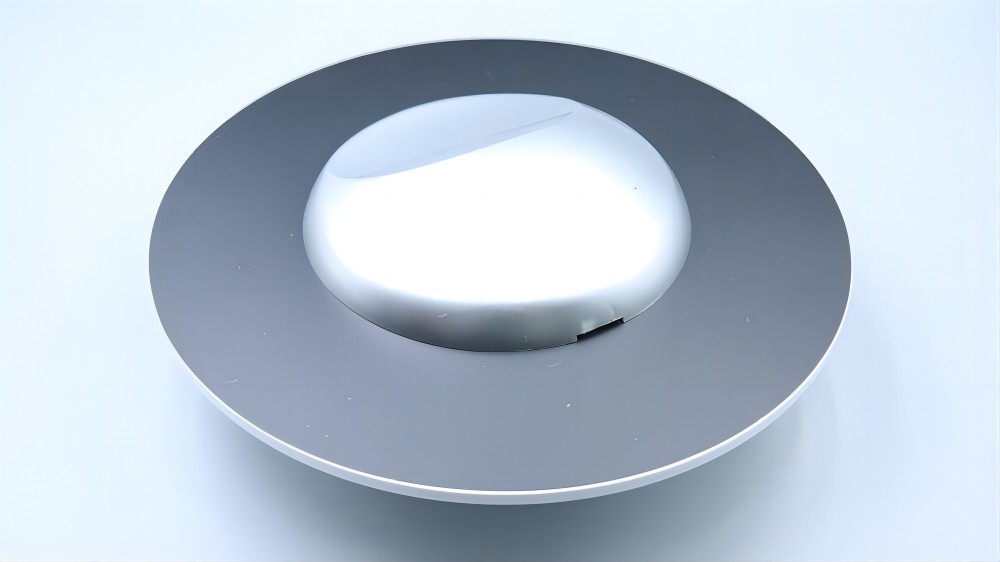

The applications of leafing aluminum paste stretch across a vast canvas, encompassing industries diverse as the human imagination itself. In the realm of paints and coatings, it reigns supreme, adorning automobiles with gleaming chrome finishes, protecting marine vessels with weather-resistant metallic barriers, and adding a touch of industrial elegance to equipment and machinery. From the sleek curves of a sports car to the rugged exterior of an offshore platform, leafing aluminum paste leaves its shimmering mark.

But its influence extends far beyond the utilitarian. In the world of plastics, it breathes life into everyday objects, transforming ordinary toys into shimmering treasures and elevating cosmetic packaging to the realm of art. Imagine a child’s delight at a toy car, its plastic body now ablaze with a pearlescent sheen, or the luxurious feel of a cosmetic compact adorned with a subtle golden glint. These are just a glimpse into the transformative power of leafing aluminum paste in the realm of plastics.

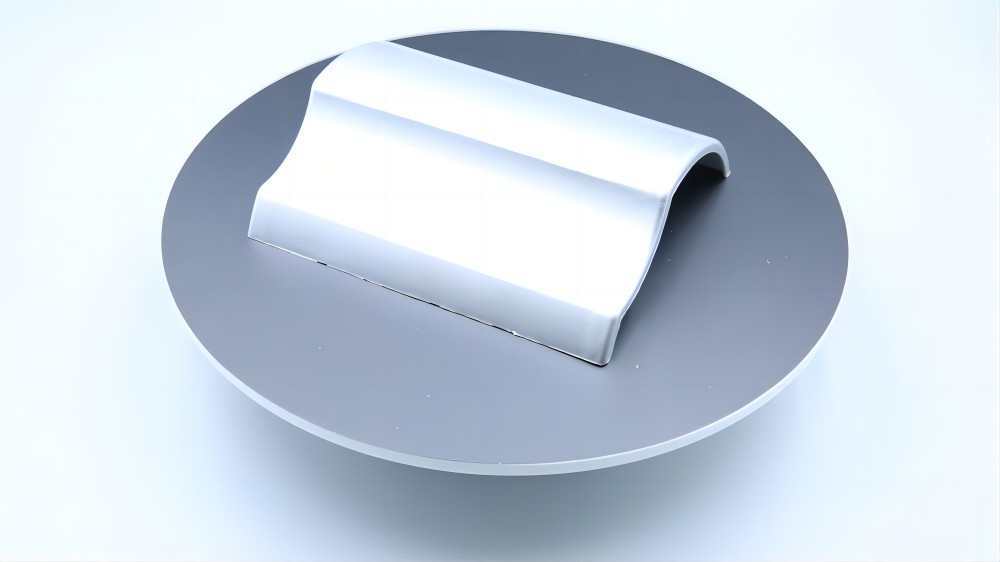

Where Art Meets Science: Unleashing Creativity

For the artistic soul, leafing aluminum paste is an open invitation to boundless exploration. Its ability to grace diverse surfaces – wood, paper, fabric – with metallic accents makes it a dream come true for crafters and artists. Imagine the possibilities: a vintage chest of drawers reborn with a shimmering copper patina, a handmade greeting card embellished with delicate silver accents, or a fabric lampshade radiating a warm, golden glow. These are just a few brushstrokes on the canvas of creativity that leafing aluminum paste unlocks.

Even the world of food decoration feels its touch, albeit with a cautious nod to safety. Certain food-grade formulations allow for the creation of edible accents, adding a touch of shimmering magic to cakes, pastries, and other culinary delights. Imagine a wedding cake adorned with delicate edible silver flakes, or cupcakes sparkling with a festive dusting of edible gold. Used responsibly, leafing aluminum paste can add a touch of whimsy and elegance to the edible canvas.

A Deeper Dive: Exploring the Technical Nuances

Beyond the surface-level understanding of leafing aluminum paste, lies a fascinating world of technical intricacies. Delving deeper into these nuances unveils a layer of complexity that further underscores its remarkable versatility.

Types of Leafing Aluminum Paste

Leafing aluminum paste isn’t a singular entity; it exists in a spectrum of variations, each tailored to specific needs. One key distinction lies in the solvent or oil used as the carrier. Water-based options, as mentioned earlier, boast environmental friendliness and ease of cleanup, while solvent-based pastes offer superior adhesion and durability, particularly for outdoor applications.

Furthermore, the flakes themselves come in a range of sizes and shapes, influencing the final finish. Larger flakes create a bolder, more reflective effect, while smaller flakes offer a smoother, pearlescent sheen. Additionally, the specific type of stearic acid used in the coating affects the way the flakes interact with the carrier and the final surface texture.

Adhesion and Compatibility

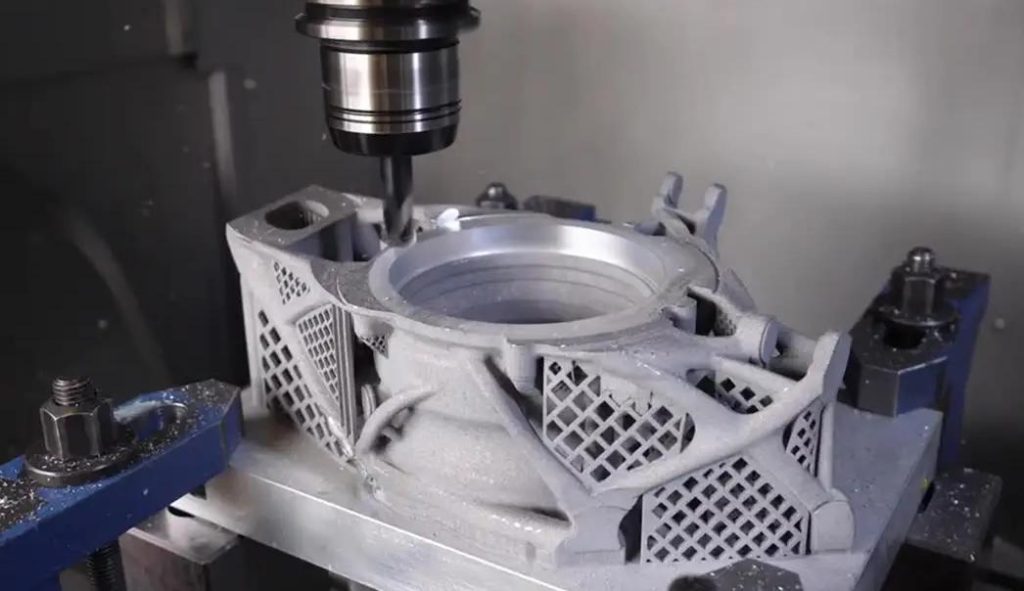

Not every surface readily welcomes the embrace of leafing aluminum paste. Understanding the compatibility of the paste with different materials is crucial for successful application. Some surfaces, like well-primed wood or metal, readily accept the paste, while others, like raw plastic or porous materials, may require additional preparation or specialized formulations to achieve optimal adhesion.

Moreover, factors like temperature and humidity can impact the drying process and the final finish. Applying the paste in controlled environments and adhering to proper drying times are essential for ensuring a flawless and lasting result.

The Science of Light and Reflection

The magic of leafing aluminum paste lies not just in its composition but also in its interaction with light. The flakes, due to their microscopic size and metallic nature, act as tiny mirrors, reflecting light at specific angles. This phenomenon is what gives rise to the dazzling metallic finishes we witness. Understanding the principles of light reflection and refraction allows for the manipulation of the paste to achieve specific effects. Varying the flake size, concentration in the carrier, and application techniques can all influence the intensity and hue of the reflected light, creating a kaleidoscope of possibilities.

Beyond the Material: Responsible Innovation and Sustainability

As we revel in the transformative power of leafing aluminum paste, it’s crucial to acknowledge our responsibility towards sustainable practices. The aluminum mining industry, while vital to the creation of this material, faces environmental concerns. Therefore, choosing responsibly sourced aluminum and exploring alternatives like recycled aluminum flakes become crucial steps towards minimizing the environmental footprint.

Furthermore, advocating for responsible waste management practices throughout the manufacturing and application process is essential. Exploring water-based options, utilizing biodegradable carriers when possible, and implementing proper disposal methods for used paste are all steps towards ensuring a sustainable future for this versatile material.

A Note of Caution: Safety Considerations

While the allure of leafing aluminum paste is undeniable, it’s crucial to remember that, like any potent tool, it demands respect and responsible use. The aluminum flakes, though minute, can pose a risk of skin and eye irritation. Therefore, donning gloves and safety glasses whenever handling the paste is paramount. Additionally, inhaling the dust created during application can be harmful, necessitating proper ventilation and avoiding close contact. Finally, keeping the paste out of reach of children and pets is essential for their safety.

Conclusion: A Legacy of Innovation, A Canvas of Endless Possibilities

Leafing aluminum paste, with its captivating blend of science, art, and industry, has carved a unique niche in the world of materials. Its journey, from humble beginnings to boundless applications, is a testament to human ingenuity and our constant pursuit of innovation. As we delve deeper into its technical complexities and embrace responsible practices, the future of this versatile material shimmers with possibilities. From the gleaming facades of tomorrow’s cities to the intricate details of artistic expression, leafing aluminum paste promises to continue inspiring and transforming the world around us.