Flat aluminum microchannel tubes are a transformative advancement in thermal management solutions. These innovative tubes offer significant advantages over traditional heat exchanger tubes, making them a highly sought-after technology across various industries. This article explores the structural characteristics of flat aluminum microchannel tubes and delves into their diverse applications.

What are Flat Aluminum Microchannel Tubes?

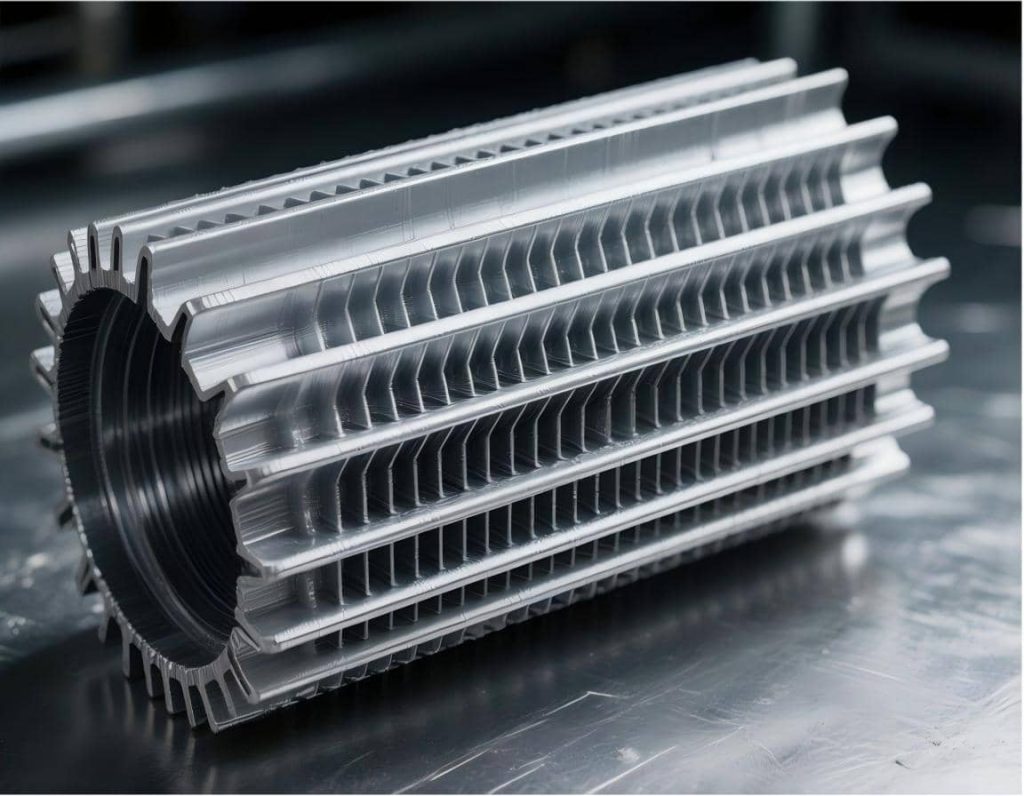

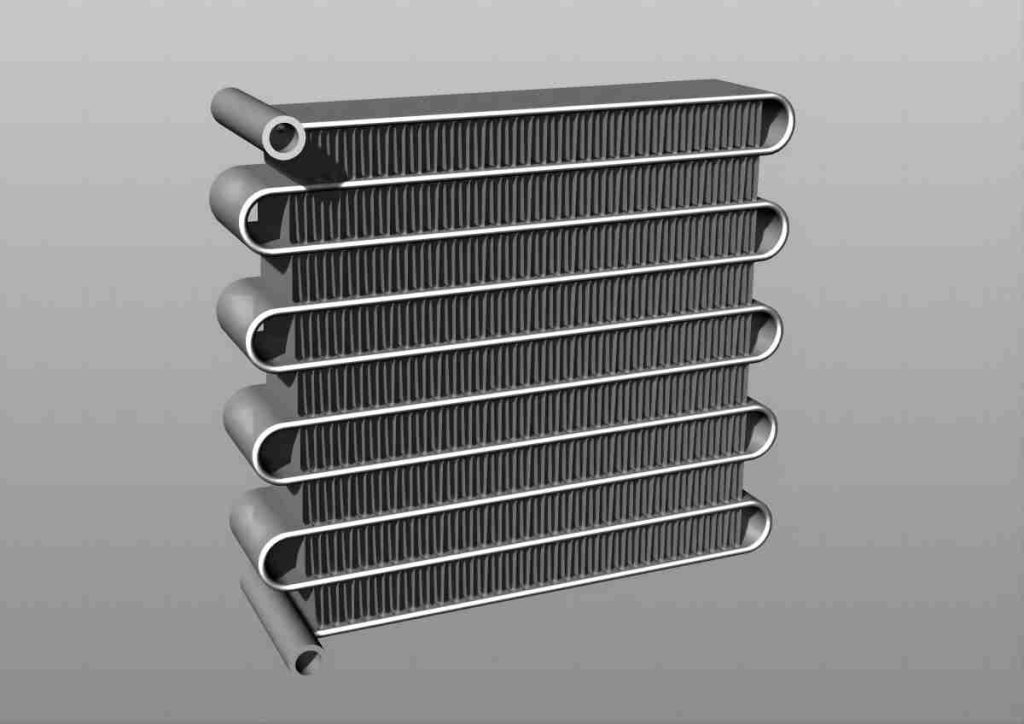

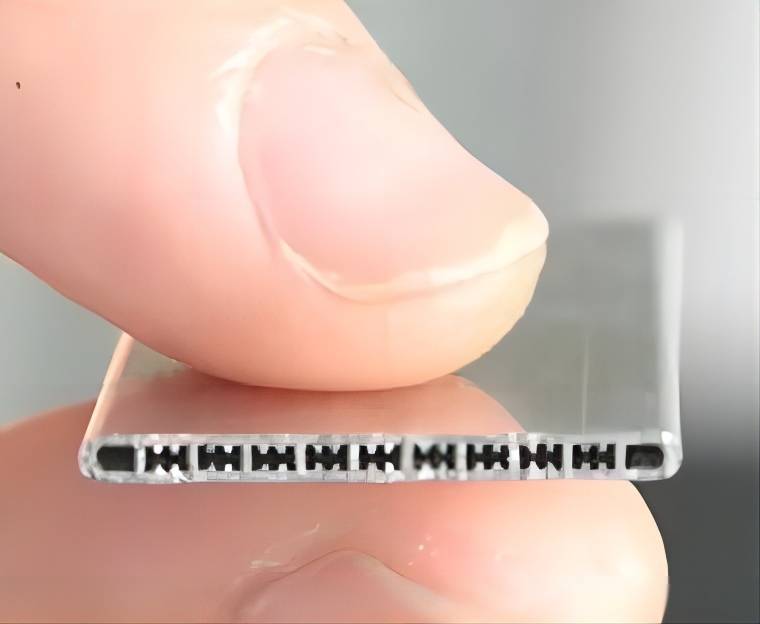

Flat aluminum microchannel tubes, also known as multi-port extruded tubes (MPE tubes), possess a distinct structure that sets them apart from conventional tubes. They are characterized by a flat, rectangular profile extruded from aluminum. The defining feature of these tubes lies within their walls – a network of microscopic channels. These microchannels significantly increase the internal surface area of the tube compared to a traditional, single-channel design.

Aluminum: The Ideal Choice for Thermal Efficiency

The selection of aluminum as the primary material for these tubes is not without reason. Aluminum boasts an exceptional combination of properties that make it perfect for thermal management applications. Here’s a closer look at the key advantages of aluminum in this context:

- High Thermal Conductivity: Aluminum possesses a naturally high thermal conductivity, which allows it to efficiently transfer heat away from a source. This translates to superior heat dissipation capabilities for the microchannel tubes.

- Lightweight: Compared to other materials commonly used in heat exchangers, aluminum is significantly lighter. This characteristic is crucial in applications where weight reduction is a priority, such as the automotive industry.

- Good Strength: Despite its lightweight nature, aluminum offers adequate structural strength for the microchannel tubes. This ensures they can withstand the internal pressure associated with fluid flow within the channels.

- Corrosion Resistance: Certain aluminum alloys exhibit excellent resistance to corrosion. This property is particularly valuable in applications where the tubes come into contact with potentially corrosive fluids.

Applications of Flat Aluminum Microchannel Tubes

The unique structural characteristics and advantageous material properties of flat aluminum microchannel tubes have opened doors to their utilization in a wide range of applications. Here are some prominent examples across various industries:

- Automotive Industry: The automotive industry is a major beneficiary of flat aluminum microchannel tubes. Their compact size and efficient heat transfer make them ideal for several critical components:

- Engine Cooling Systems: Microchannel tubes can be integrated into engine cooling systems, enhancing heat removal from the engine block and cylinder head. This translates to improved engine performance and efficiency.

- Air Conditioning Systems: In car air conditioning systems, microchannel tubes can be employed in condensers and evaporators. Their increased surface area allows for more efficient heat exchange, leading to faster cabin cooling.

- Battery Thermal Management Systems: The rise of electric vehicles has necessitated effective battery thermal management systems. Flat aluminum microchannel tubes can be incorporated into these systems to maintain optimal battery temperature, ensuring efficient operation and extended battery life.

- Hydraulic System Radiators: Hydraulic systems used in various automotive applications generate significant heat. Microchannel tubes can be utilized in hydraulic system radiators to effectively dissipate this heat, preventing component overheating and ensuring system reliability.

- Air Conditioning and Refrigeration: The air conditioning and refrigeration industry can leverage the benefits of flat aluminum microchannel tubes to improve the efficiency of heat exchangers. By incorporating these tubes into condensers and evaporators, manufacturers can achieve:

- Enhanced Heat Transfer: The increased surface area of the microchannels facilitates more efficient heat transfer, leading to improved system performance.

- Compact Design: The smaller footprint of microchannel tubes allows for the development of more compact heat exchangers, saving valuable space in air conditioning and refrigeration units.

- Electronic Equipment Thermal Management: The ever-increasing heat generation of electronic components poses a significant challenge. Flat aluminum microchannel tubes offer a solution for efficient thermal management in various electronic devices:

- CPU and GPU Cooling: By integrating microchannel tubes into heat sinks for CPUs (central processing units) and GPUs (graphics processing units), manufacturers can achieve superior heat dissipation, ensuring optimal performance and preventing component damage.

- Power Electronics Cooling: Power electronics, such as inverters and converters, generate significant heat. Microchannel tubes can be employed in their cooling systems to maintain safe operating temperatures and extend component lifespan.

Beyond the Current: Exploring Future Applications

The potential applications of flat aluminum microchannel tubes extend beyond the aforementioned examples. As research and development in this field continue, we can expect to see these innovative tubes integrated into a wider range of technologies. Potential future applications include:

- Medical Devices: Microchannel tubes could be used in medical devices for applications such as blood temperature regulation or localized heat therapy.

- Aerospace Industry: The lightweight and efficient heat transfer properties of microchannel tubes make them attractive for thermal management systems in aircraft and spacecraft.

- Consumer Electronics: The growing demand for high-performance and compact electronic devices could lead to the use of microchannel tubes in laptops, smartphones, and other consumer electronics.

Conclusion

Flat aluminum microchannel tubes represent a significant advancement in thermal management technology. Their unique structure, combined with the advantageous properties of aluminum, makes them a compelling choice for various applications across diverse industries. As manufacturing processes become more streamlined and cost-effective, we can expect to see even wider adoption of these innovative tubes. Additionally, ongoing research and development efforts hold promise for further optimizing their performance and exploring their potential in novel applications. Flat aluminum microchannel tubes are poised to play a vital role in the future of efficient heat transfer solutions.