Aluminum is one of the most widely used metals in various industries, thanks to its excellent properties like strength, durability, and lightweight. In the automotive and aerospace industries, the demand for aluminum components is significantly high. One of the key components made of aluminum is a seamless aluminum tube. Seamless aluminum pipes are used in various applications like engine components, exhaust systems, structural components, fuel systems, heat exchangers, hydraulic systems, and pneumatic systems, among others. This article aims to discuss the advantages of using seamless aluminum pipes in the automotive and aerospace industries.

Properties of Seamless Aluminum Tube

The seamless aluminum tube offers several advantages over other materials like steel, copper, and brass. These advantages are due to the unique properties of aluminum, including:

- Strength and Durability: Aluminum has a high strength-to-weight ratio, making it ideal for applications where strength is crucial. Additionally, aluminum is corrosion-resistant, which means it can withstand harsh environments and is less likely to rust or corrode.

- Lightweight: Aluminum is one of the lightest metals available, making it perfect for applications that require lightweight components. The use of seamless aluminum pipe and tube can significantly reduce the weight of a vehicle or aircraft, leading to increased fuel efficiency.

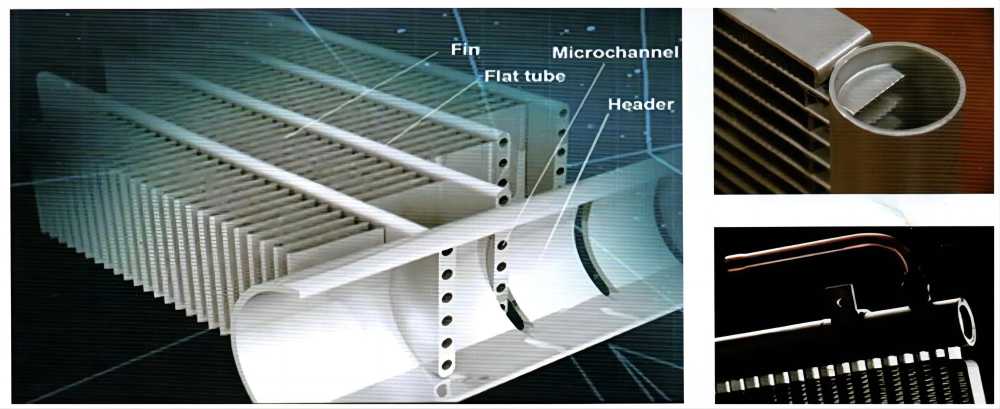

- High Thermal Conductivity: Aluminum is an excellent conductor of heat, which means it can efficiently transfer heat from one point to another. This property makes aluminum ideal for use in heat exchangers and other applications that require efficient heat transfer.

- Low Maintenance: Aluminum requires very little maintenance compared to other materials. It is resistant to corrosion, and it does not require painting or coating to protect it from the elements.

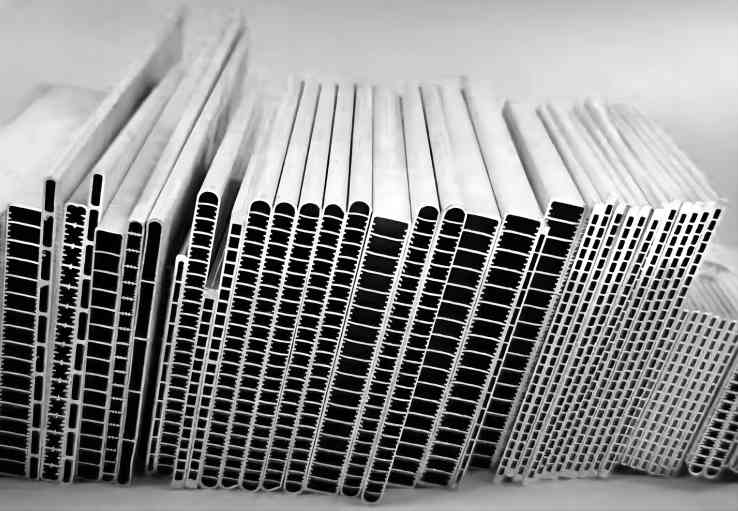

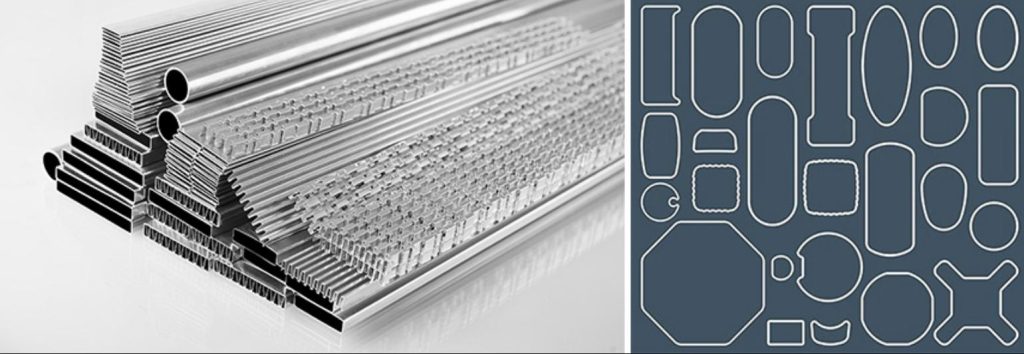

Manufacturing Process of Seamless Aluminum Pipe

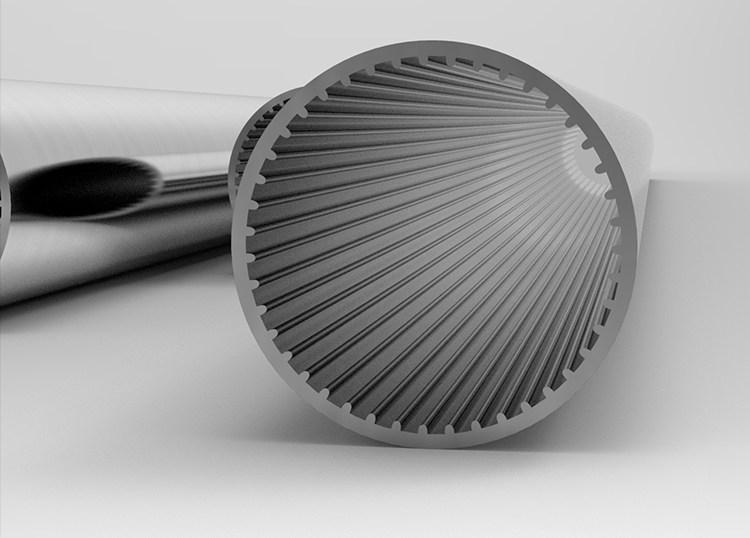

Seamless aluminum pipes are manufactured using a process called extrusion. In this process, a solid aluminum billet is heated to a specific temperature and then forced through a die to create the desired shape. The resulting product is a seamless tube or pipe that has no welds or seams. The seamless nature of the product offers several advantages, including:

- High-Quality Surface Finish: Seamless aluminum pipe and tube have a smooth, uniform surface finish, which makes them ideal for applications where appearance is crucial.

- Precision Tolerance: Seamless aluminum pipe and tube can be manufactured to very tight tolerances, which means they are suitable for applications that require high precision.

- Excellent Machinability: Seamless aluminum pipe and tube are easy to machine, which means they can be quickly and efficiently cut to the desired length and shape.

Applications of Seamless Aluminum Pipe and Tube in the Automotive Industry

The automotive industry is one of the largest consumers of seamless aluminum pipes and tubes. Some of the common applications include:

- Engine Components: Seamless aluminum pipes and tubes are used to create various engine components like intake manifolds, exhaust manifolds, and cylinder heads. The high strength and lightweight properties of aluminum make it ideal for these applications.

- Exhaust Systems: Seamless aluminum tubes are used to create exhaust systems in cars and trucks. Aluminum is resistant to corrosion, which means it can withstand the harsh environment inside the exhaust system.

- Suspension Systems: Seamless aluminum tubes are used to create suspension components like shock absorbers and struts. The lightweight and high-strength properties of aluminum make it ideal for these applications.

- Fuel Systems: Seamless aluminum pipes and tubes are used to create fuel lines, tanks, and other components in the fuel system. The high thermal conductivity of aluminum ensures efficient heat transfer, which is crucial in fuel systems.

Applications of Seamless Aluminum Pipe and Tube in the Aerospace Industry

The aerospace industry is another significant consumer of seamless aluminum pipe and tube. Some of the common applications include:

- Structural Components: Seamless aluminum pipes and tubes are used to create various structural components in aircraft, including wings, fuselage, and landing gear. The lightweight and high-strength properties of aluminum make it an ideal material for these applications.

- Heat Exchangers: Seamless aluminum tubes are used to create heat exchangers in aircraft. The high thermal conductivity of aluminum ensures efficient heat transfer, which is crucial in these applications.

- Fuel Systems: Seamless aluminum pipes and tubes are used to create fuel lines and other components in aircraft fuel systems. Aluminum’s high strength and corrosion resistance properties ensure the safety and reliability of the fuel system.

- Hydraulic Systems: Seamless aluminum tubes are used to create hydraulic lines and other components in aircraft hydraulic systems. Aluminum’s lightweight and high-strength properties make it an ideal material for these applications.

Advantages of Seamless Aluminum Pipe and Tube in Automotive and Aerospace Industries

Seamless aluminum pipe and tube offer several advantages over other materials like steel, copper, and brass. These advantages include:

- High Strength-to-Weight Ratio: Aluminum is one of the lightest metals available, but it is also one of the strongest. The high strength-to-weight ratio of aluminum makes it an ideal material for applications where weight is a concern, like in the automotive and aerospace industries.

- Corrosion Resistance in Harsh Environments: Aluminum is highly resistant to corrosion, making it ideal for use in harsh environments like automotive exhaust systems and aircraft fuel systems.

- Resistance to High Temperatures: Aluminum has a high melting point, which means it can withstand high temperatures without deforming or melting. This property makes aluminum ideal for use in heat exchangers and other high-temperature applications.

- Flexibility and Versatility in Design: Seamless aluminum pipe and tube can be easily shaped and formed into various designs, making it an ideal material for complex components in the automotive and aerospace industries.

- Easy to Fabricate and Weld: Aluminum is easy to fabricate and weld, making it easy to manufacture complex components quickly and efficiently.

Conclusion

In conclusion, a seamless aluminum tube is a perfect choice for the automotive and aerospace industries. The unique properties of aluminum, including its strength, lightweight, corrosion resistance, and high thermal conductivity, make it an ideal material for various applications in these industries. The seamless nature of the product offers several advantages like a high-quality surface finish, precision tolerance, and excellent machinability. With the increasing demand for lightweight, high-performance components, seamless aluminum pipe and tube will continue to play a critical role in the automotive and aerospace industries in the years to come. CHAL is one of the professional aluminum manufacturers in China, contact us now, and you will get warm service.