Aluminum paste, a seemingly unassuming silver goo, might surprise you with its vast and versatile applications. While its metallic sheen adds a touch of elegance to decorative finishes, its hidden potential lies in a range of industries, from fuel-efficient car coatings to cutting-edge solar panels. In this article, we’ll delve into six prominent uses of aluminum paste, showcasing its surprising range and potential.

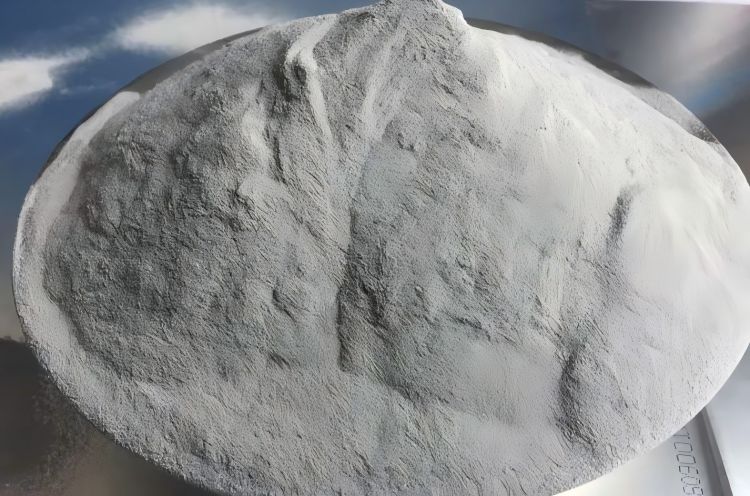

What is Aluminum Paste?

Made from finely ground aluminum flakes suspended in a carrier medium, aluminum paste offers a unique combination of properties. At its core, aluminum paste is a potent reflector of light and heat. The microscopic flakes act as miniature mirrors, bouncing radiation away from the surface. This property, coupled with its excellent adhesion and conductivity, make it an ideal material for a variety of uses across diverse sectors.

6 Common Applications of Aluminum Paste

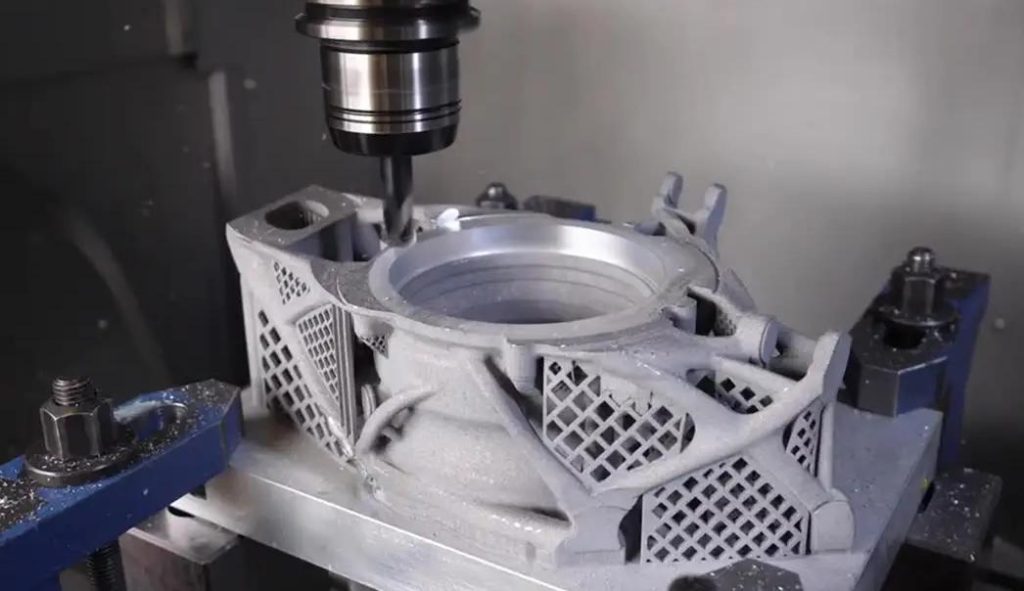

1. Aluminum Paste in the Automotive Industry: Fuel-Efficient Solutions

Automakers leverage aluminum paste’s reflective qualities to combat heat build-up in engines and exhaust systems. Applied as a coating, it reduces under-hood temperatures, leading to improved engine performance and fuel efficiency. Additionally, its heat-shielding properties protect surrounding components, minimizing wear and tear.

2. Aluminum Paste in Construction: Sustainable Solutions

In the construction industry, aluminum paste shines as a sustainable alternative to traditional waterproofing materials. When incorporated into roofing membranes, it reflects infrared radiation, keeping buildings cooler and reducing reliance on air conditioning. This translates to lower energy consumption and a smaller carbon footprint. Furthermore, its reflective surface can contribute to the urban heat island effect mitigation.

3. Aluminum Paste in Printing and Packaging: Enhances Visual Communication

The world of graphic design and packaging isn’t immune to the allure of aluminum paste. Its metallic sheen adds a touch of luxury and sophistication to labels, product boxes, and even greeting cards. The reflective properties can also be used to create eye-catching holographic effects, capturing attention on store shelves.

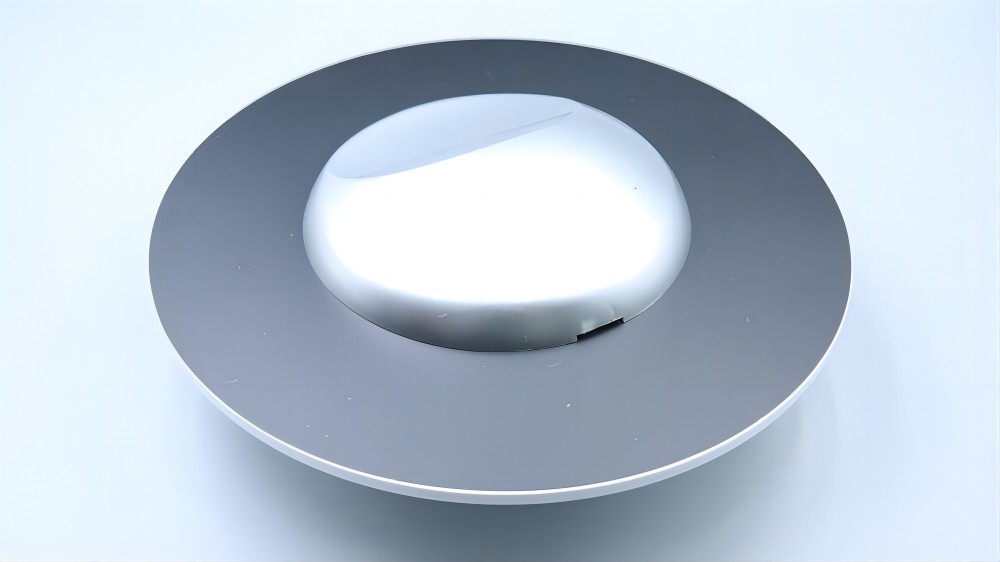

4. Aluminum Paste in the Solar Industry: Improving Solar Panel Efficiency

Harnessing the sun’s power? Aluminum paste plays a crucial role here too. When applied to the back of solar panels, it reflects stray light back onto the photovoltaic cells, boosting their efficiency by up to 5%. This seemingly small increase translates to significantly more energy captured, making solar power even more viable and sustainable.

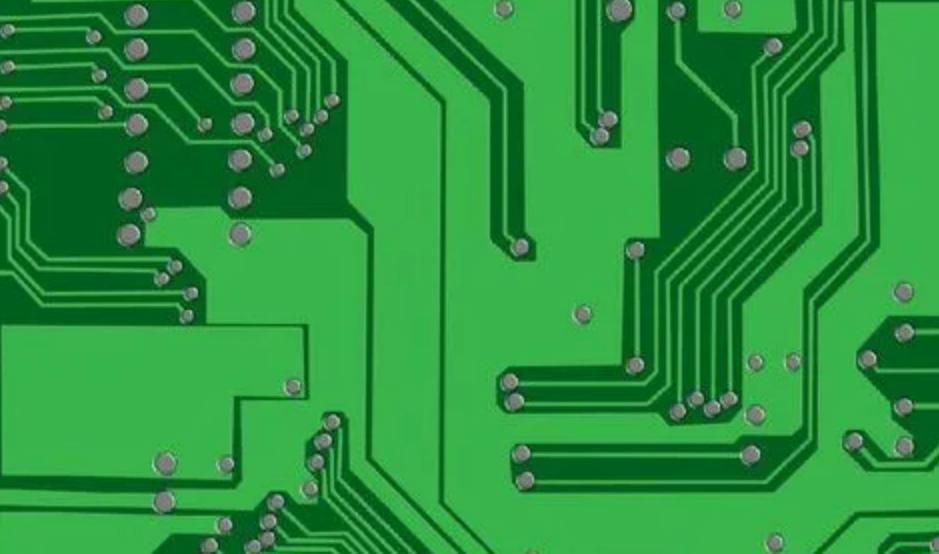

5. Aluminum Paste in Electronics and Beyond: Improving Conductivity

Beyond reflecting light and heat, aluminum paste excels at conducting electricity. In electronic circuits, it can be used to fill gaps or create heat sinks, ensuring optimal flow and dissipation of electricity. This application extends beyond traditional electronics, even finding use in the aerospace industry, where it assists in shielding sensitive equipment from electromagnetic interference.

6. Aluminum Paste in Emerging Technologies

The potential of aluminum paste doesn’t stop with established industries. Researchers are exploring its use in emerging technologies like flexible electronics and biosensors. Its reflective and conductive properties hold promise for applications in wearable devices and medical diagnostics, pushing the boundaries of what’s possible.

Conclusion:

Aluminum paste, once solely associated with industrial applications, has emerged as a surprisingly versatile material with applications far exceeding expectations. From enhancing fuel efficiency in cars to boosting solar panel output, its reflective and conductive properties find use in a diverse range of industries. As research continues, one can only imagine the future applications this humble paste may unlock, forever defying its unassuming appearance.