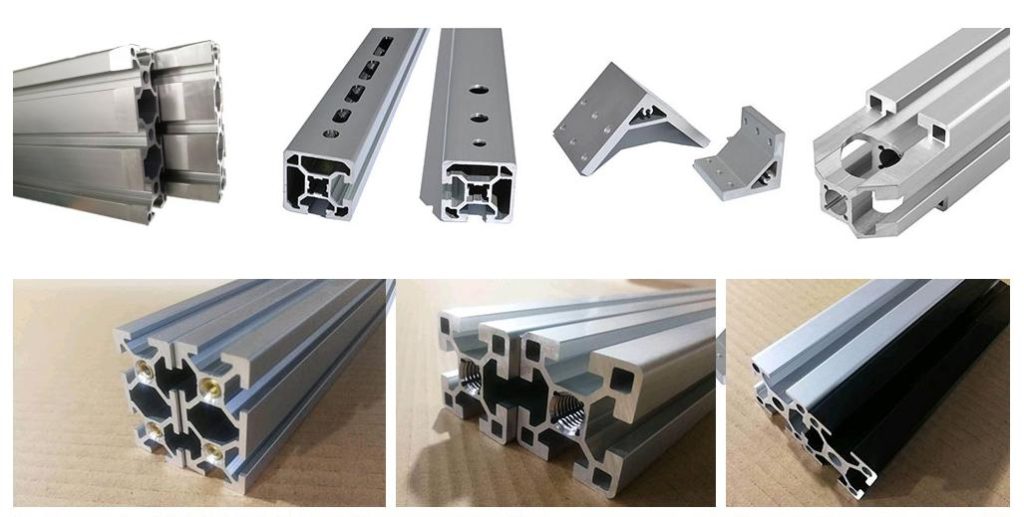

In the world of aerospace and automotive engineering, innovation knows no bounds. The relentless pursuit of efficiency, performance, and sustainability drives technological advancements that shape the future of these industries. One such innovation that has left an indelible mark is the incorporation of aluminum motor housings. These lightweight and robust components have revolutionized aerospace and automotive applications, offering a host of benefits that redefine the way we think about propulsion systems.

Aluminum Motor Housings in Aerospace

In the aerospace industry, where every ounce counts, aluminum motor housings have made a significant impact. The reduced weight translates directly to fuel efficiency and enhanced overall performance. Aircraft engines, from turbofans to turboprops, benefit from the reduced weight of aluminum housings without compromising structural integrity. This weight reduction translates not only to fuel savings but also to extended range and payload capabilities.

- Efficiency at Altitude

Aluminum’s ability to efficiently dissipate heat further cements its role in aerospace applications. In the high-temperature environments of jet engines, aluminum motor housings efficiently channel heat away from critical components. This not only prolongs the life of the motor but also contributes to the safety and reliability of the aircraft.

Aluminum Motor Housings in Automotive

The automotive industry, like aerospace, has witnessed a paradigm shift with the integration of aluminum motor housings. Automakers are continually seeking ways to improve fuel efficiency, reduce emissions, and enhance vehicle performance. Aluminum’s attributes align perfectly with these objectives, making it an ideal choice for motor housings.

- Lightweight Prowess

The automotive sector’s fascination with aluminum stems from its prowess in weight reduction. An aluminum motor housing significantly reduces the overall weight of the vehicle, leading to improved fuel economy. This weight reduction isn’t just limited to conventional vehicles; it plays a pivotal role in the rise of electric and hybrid vehicles as well, contributing to extended battery life and range.

- Temperature Management for Performance

In the world of automotive engineering, managing heat is paramount. Aluminum motor housings excel in this aspect, aiding in the efficient dissipation of heat generated during the combustion process. Whether it’s a high-performance sports car or a daily commuter, effective heat management ensures that the engine operates optimally, enhancing both performance and longevity.

Synergy of Strength and Sustainability of Aluminum Motor Housings

The aerospace and automotive industries are also recognizing the sustainability benefits of aluminum motor housings. Aluminum is one of the most recyclable materials on the planet, aligning perfectly with the growing emphasis on environmental responsibility. The ability to recycle aluminum without compromising its integrity contributes to a circular economy and reduces the environmental impact of these industries.

Conclusion

The integration of aluminum motor housings into aerospace and automotive applications marks a new era of propulsion. The marriage of aluminum’s attributes with the demands of these industries has redefined the possibilities of lightweight design, heat management, and sustainability. From reducing emissions to extending vehicle range, aluminum motor housings have become pivotal components in driving efficiency and innovation. As the aerospace and automotive industries continue to evolve, the role of aluminum motor housings will remain a beacon of ingenuity, shaping the path to a more efficient and sustainable future.