In the world of construction, engineering, and design, materials matter. Choosing the right material for a project can impact everything from strength and durability to weight, cost, and environmental impact. While steel has long been the go-to choice for demanding applications, aluminum pipes have emerged as indispensable components in modern construction and engineering projects due to their lightweight yet sturdy nature. Among the various types available, thick-wall aluminum pipes stand out for their remarkable ability to handle diverse projects with efficiency and durability. In this article, we delve into the characteristics and applications of thick-wall aluminum pipes, highlighting their versatility and importance across different industries.

What is a Thick-wall Aluminum Pipe?

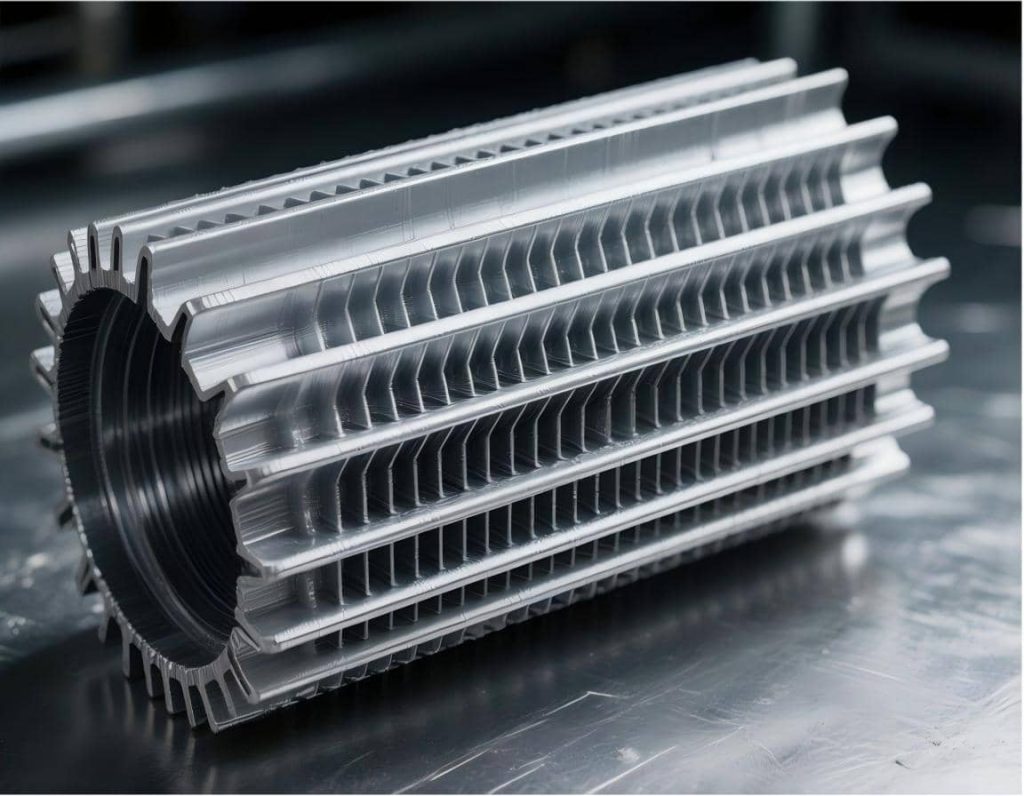

Thick-wall aluminum pipe refers to a type of aluminum tubing that has a comparatively larger thickness in its walls compared to standard aluminum pipes. The term “thick-wall” indicates that the pipe has been manufactured with thicker walls, which enhances its structural integrity, durability, and ability to withstand heavier loads and pressures. In general, aluminum pipes with a wall thickness greater than 1/8 inch (3.175 millimeters) are often considered thick-wall pipes. However, the threshold for what is considered “thick-wall” can vary based on the specific requirements of the application, engineering standards, and industry practices.

Thick-wall aluminum pipes are typically produced through an extrusion process, where aluminum billets are forced through a die to form the desired shape and dimensions. During the extrusion process, the thickness of the walls can be controlled and adjusted according to the specific requirements of the application. These pipes are available in various diameters and thicknesses to suit different industrial, commercial, and residential needs. They are commonly used in construction, automotive, aerospace, marine, and other industries where lightweight yet strong and durable materials are required.

One of the defining features of thick-wall aluminum pipes is their robustness. Unlike thinner-walled counterparts, these pipes offer enhanced resistance to bending, torsion, and external forces, making them ideal for supporting heavy loads and withstanding harsh environmental conditions. The increased thickness also contributes to improved corrosion resistance, ensuring longevity even in corrosive environments such as marine or industrial settings.

Advantages of Thick-wall Aluminum Pipe

Thick-wall aluminum pipes offer several advantages over pipes made from other materials:

- Strength and Durability: The thicker walls provide increased strength and durability, making them suitable for applications where structural integrity is critical.

- Lightweight: Despite their robust construction, thick-wall aluminum pipes remain lightweight compared to steel or other materials, making them easier to handle and install.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer on its surface, which enhances its resistance to corrosion and rust, especially in harsh environments such as marine or industrial settings.

- Versatility: Thick-wall aluminum pipes can be easily fabricated, welded, and machined to meet specific project requirements. They can also be anodized or coated for additional protection and aesthetic purposes.

- Sustainability: Aluminum is a highly recyclable material, making thick-wall aluminum pipes an environmentally friendly choice for sustainable construction and manufacturing practices.

Thick-wall aluminum pipes are commonly used in various applications, including structural supports, frames, handrails, heat exchangers, hydraulic systems, and pneumatic systems. They offer a cost-effective and reliable solution for a wide range of projects, contributing to efficiency, longevity, and performance across different industries.

What are the Diverse Applications of Using Thick-Wall Aluminum Pipe?

1. Construction:

- Scaffolding and Support Structures: The lightweight yet robust nature of thick-wall aluminum pipe makes it a popular choice for temporary structures like scaffolding. It reduces weight on buildings, simplifies assembly and disassembly, and offers excellent corrosion resistance for outdoor use.

- Trusses and Beams: In permanent structures, thick-wall aluminum pipe can be used for trusses and beams, offering strength and aesthetics. Its lighter weight compared to steel reduces structural load and can be a cost-effective alternative.

2. Marine:

- Boatbuilding: From high-performance racing yachts to robust fishing vessels, thick-wall aluminum pipe finds its place in various boat components. Its corrosion resistance ensures longevity in saltwater environments, while its strength allows for lightweight yet sturdy construction.

- Railings and Masts: The sleek look and exceptional durability of thick-wall aluminum pipe make it ideal for railings and masts. It withstands the harsh marine environment and requires minimal maintenance compared to traditional materials.

3. Oil & Gas:

- Pipelines and Pressure Vessels: The strength and corrosion resistance of thick-wall aluminum pipe make it a valuable material for high-pressure pipelines and vessels used in oil and gas transportation and processing. Its lighter weight can also reduce transportation and installation costs.

- Heat Exchangers: Due to its excellent heat transfer properties and corrosion resistance, thick-wall aluminum pipe finds use in heat exchangers, contributing to efficient energy transfer in oil and gas operations.

4. Aerospace:

- Aircraft Frames and Components: The strength-to-weight ratio of thick-wall aluminum pipe makes it a crucial material in aircraft construction. It helps reduce weight, enhancing fuel efficiency and performance while maintaining structural integrity.

- Landing Gear Components: Landing gear components require high strength and fatigue resistance. Thick-wall aluminum pipe, with its specific alloys, meets these demands, ensuring safe and reliable aircraft operation.

5. Other Diverse Applications:

- Furniture: The aesthetics and strength of thick-wall aluminum pipe make it a popular choice for modern furniture designs. It can be used for table bases, chair frames, and even lighting fixtures, offering a sleek and durable alternative to traditional materials.

- Architectural Accents: Architects are increasingly incorporating thick-wall aluminum pipe into their designs due to its versatility and visual appeal. It can be used for cladding, railings, canopies, and other decorative elements, adding a touch of modern sophistication.

By leveraging its unique properties, thick-wall aluminum pipe tackles diverse projects with remarkable success. While the initial cost might be higher compared to some materials, its long-term benefits outweigh the initial investment. Its durability, low maintenance requirements, and recyclability contribute to its sustainability, making it an attractive choice for environmentally conscious projects.

Conclusion

In conclusion, the versatility and durability of thick-wall aluminum pipes make them indispensable components for diverse projects across various industries. From construction and automotive to aerospace and renewable energy, these pipes offer exceptional strength-to-weight ratios, corrosion resistance, and structural integrity, making them ideal for a wide range of applications.

As the demand for sustainable and efficient infrastructure continues to rise, thick-wall aluminum pipes provide a cost-effective and reliable solution for engineers, designers, and project managers. By understanding the unique characteristics and advantages of thick-wall aluminum pipes, you can better choosing high-quality materials that meet the stringent requirements of your projects from aluminum pipe suppliers.