The wire and cable industry uses a variety of metal conductors, but the two most common are copper wire and aluminum wire. Because each metal type has unique properties, they are best suited for different applications or purposes.

Copper Wire vs. Aluminum Wire: Concept

Copper is the most often utilized conductor in commercial, industrial, and residential construction. Due to its composition of elements, copper is a superior conductor that is relatively inexpensive (in comparison to gold and silver which are both excellent conductors).

There have been aluminum wire for a very long time. Aluminum, which was primarily employed for utility applications, is now being used more and more in feeder applications in major commercial, industrial, and residential projects. Your primary breaker panel likely has aluminum going into your home.

Copper Wire vs. Aluminum Wire: Features & Benefits

In addition to being widely used in most applications, copper has a number of qualities and advantages, including a high tensile strength and a higher current carrying capacity per volume, which allows for smaller conductors.

When working in confined locations, smaller conductors might be advantageous, which is one of the main reasons copper is the material of choice when wiring branch applications like a switch or outlet.

The majority of metals corrode, which can be bad for an electrical system’s effectiveness. It is important to remember that copper oxidation is semi-conductive even if precautions should be taken to prevent conductor oxidation.

Although aluminum wire is a good conductor, there are a few factors to consider before using this metal from the twenty-first century.

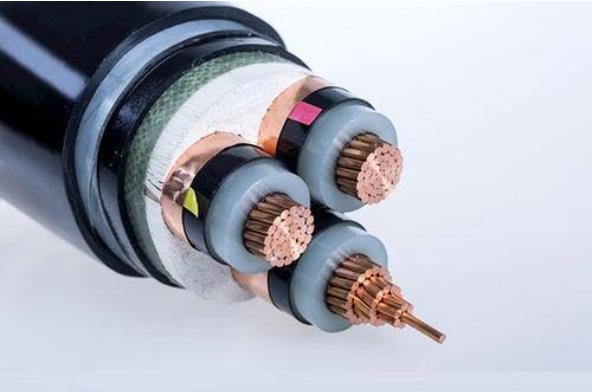

In order to accommodate the same circuit ampacity, you typically need to upsize your conductor by two sizes, for example, by substituting a 750 MCM aluminum wire for a 500 MCM copper wire. This is because aluminum wire requires a larger volume to conduct the same amount of electricity as copper does.

Wire made of aluminum is incredibly light. Despite being more extensive, the conductors will probably weigh less than a copper conductor with a comparable ampacity.

Due to the increase in size, the aluminum wire conductors will also have a greater outside diameter, but this is mediated by compact stranding, which minimizes the air gap between the strands.

However, the demand for larger conduits may result from the larger conductors. Additionally “annealed,” aluminum wire is far more flexible and resistant to mechanical wear than conventional copper conductors.

Each metal has a varied coefficient of expansion, hence aluminum wire expands and contracts at a different pace than copper wire. There must be precautions made to avoid concerns with creep, which is the migration of metal at system connection points during electrical/thermal cycling.

In the modern electrical world, dual-rated lugs provided by the manufacturer of the equipment you buy are frequently used to do this.

Copper Wire vs. Aluminum Wire: Costs

When carrying huge amounts of power, the copper wire may be prohibitively expensive because it is significantly more expensive than aluminum wire. Additionally stronger and heavier than the aluminum wire of comparable ampacity, copper is challenging to work with in longer distances.

As we mentioned earlier in this essay, aluminum oxide is an insulator while copper oxide is semi-conductive. When creating a connection at any point in your electrical system where an oxide accelerant is present, it is usual procedure to utilize an oxide-inhibiting grease (moisture or another element).

Today’s businesses place a lot of importance on return on investment (ROI). Therefore, the most evident benefit of using aluminum wire is the reduced cost of the raw material.

Aluminum is the most common ore discovered on Earth, therefore it has a high supply and a cheap, steady cost. Aluminum wire is used in everything today, from packaging to airplane bodies. It is a very economical solution when used to distribute power.

Conclusion

Copper wire and aluminum wire are both widely used for wire in commercial, industrial, and residential projects. The project, circumstance, location, budget, code compliance, and safety considerations will all affect the best wire solution.

CHAL Aluminium Corporation is a reputable manufacturer and supplier of aluminum alloy wire with excellent quality and affordable pricing. Along with high mechanical performance and safety, our products also operate very well economically.