Aluminum paste, a silvery, viscous slurry hiding within its embrace a multitude of possibilities, might seem unassuming at first glance. But under that unassuming exterior lies a hidden world of dazzling effects, practical solutions, and a versatility that stretches across industries as diverse as cosmetics and construction. Let’s dive into the intricate tapestry woven by the different types of aluminum paste, unraveling their unique characteristics and the magic they bring to various applications.

Size Matters: A Flake’s Tale of Grandeur and Delicacy

The first key to understanding aluminum paste lies in the size of its star player – the aluminum flake. These microscopic platelets, ranging from coarse giants of 45 microns to fine whispers of 5 microns, dictate the paste’s performance. Coarse flakes, like shimmering knights in metallic armor, offer high reflectivity and a pronounced metallic texture, adorning automotive paints and decorative coatings with their grandeur. Medium-sized flakes, the versatile diplomats, strike a balance between shine and concealment, finding their place in printing inks, plastics, and even cosmetics. Finally, the fine-grained finesse of small flakes empowers them to disappear seamlessly into coatings for food cans, pharmaceuticals, and electronics, offering smooth finishes and superior hiding power.

Surface Treatment: From Naked Beauty to Dressed-Up Diva

While natural, untreated aluminum flakes possess a charmingly raw, slightly dull appearance, their performance can be dramatically enhanced by a makeover. Surface treatment, the equivalent of a high-fashion makeover for these metallic flakes, dresses them in invisible garments of organic or chemical films. These coatings bestow upon them superpowers! The ability to cling tenaciously to surfaces, resist corrosion like a shield against time, and even conduct electricity with the grace of a dancer – all thanks to the wizardry of surface treatment. This, in turn, opens doors to high-performance coatings, conductive applications, and a world of specialized functions.

A Carrier for Every Canvas: Oil, Water, and the Magic of Choice

Just like artists have their preferred mediums, aluminum paste finds its canvas through different carrier fluids. The stalwart of the bunch is oil-based paste, offering stability and ease of application, its brushstrokes flowing on surfaces with familiar comfort. However, environmental concerns whisper their warnings, and water-based pastes emerge as the eco-conscious alternative. Though their application might require a touch of expertise, the canvas of sustainability they offer is worth the learning curve. Finally, solvent-based pastes, potent concoctions with quick-drying abilities and exceptional adhesion, come with a cautionary note: handle them with the respect due to potent tools.

Beyond the Ordinary: A Rainbow of Colors and Special Powers

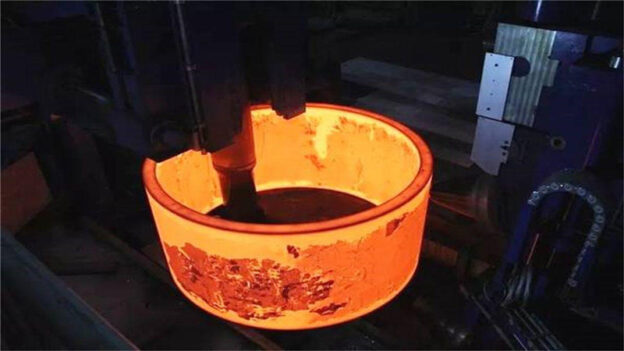

But the world of aluminum paste isn’t just about size, surface, and the carrier that binds them. It’s about pushing boundaries, about venturing beyond the confines of the ordinary. Pigmented aluminum pastes, where metallic flakes dance alongside other pigments, paint the world in a kaleidoscope of colors. Imagine copper shimmering alongside emerald green, or silver intertwined with the fiery intensity of red – the possibilities are as endless as the human imagination. And then there are the specialists, the alchemists of the aluminum paste world. Conductive pastes channel electricity, illuminating displays and steering data like invisible currents. High-temperature pastes, forged in the fires of innovation, defy the searing heat of engines and exhaust systems, protecting and performing where others would melt away.

From Humble Origins to Grand Designs: A Tapestry of Applications

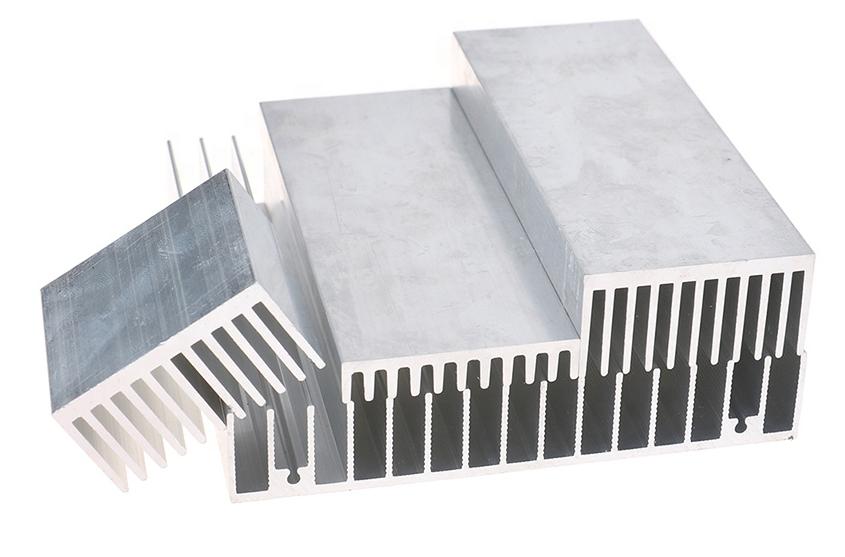

The applications of aluminum paste are as diverse as the flakes themselves. They bring a dazzling radiance to the automotive industry, coating cars in metallic majesty. They protect food cans from harmful elements, ensuring our meals stay safe and fresh. They lend their conductivity to electronic circuits, whispering data through metallic veins. They even find their way into the world of cosmetics, adding a touch of shimmer to lipsticks and eyeshadows. And let’s not forget the humble beginnings: lightweight concrete, fireproofing coatings, and even heat sinks for powerful electronics – all rely on the unique properties of different aluminum pastes.

A Final Reflection: A Future Shimmering with Possibilities

Aluminum paste, once a simple material, has transformed into a versatile palette for innovation. Its journey, from the depths of the earth to the brushstrokes of countless applications, reveals a story of scientific ingenuity and practical magic. As technology advances, new surface treatments, carrier mediums, and even flake shapes will undoubtedly emerge, expanding the canvas of possibilities even further. The future of aluminum paste shimmers with a metallic gleam, promising more dazzling effects, innovative solutions, and a continued journey into the heart of this remarkable material. So, the next time you see a car gleaming in the sun, a lipstick shimmer on a smile, or a circuit board pulsing with data, remember the humble aluminum paste, the silent hero behind the metallic magic.