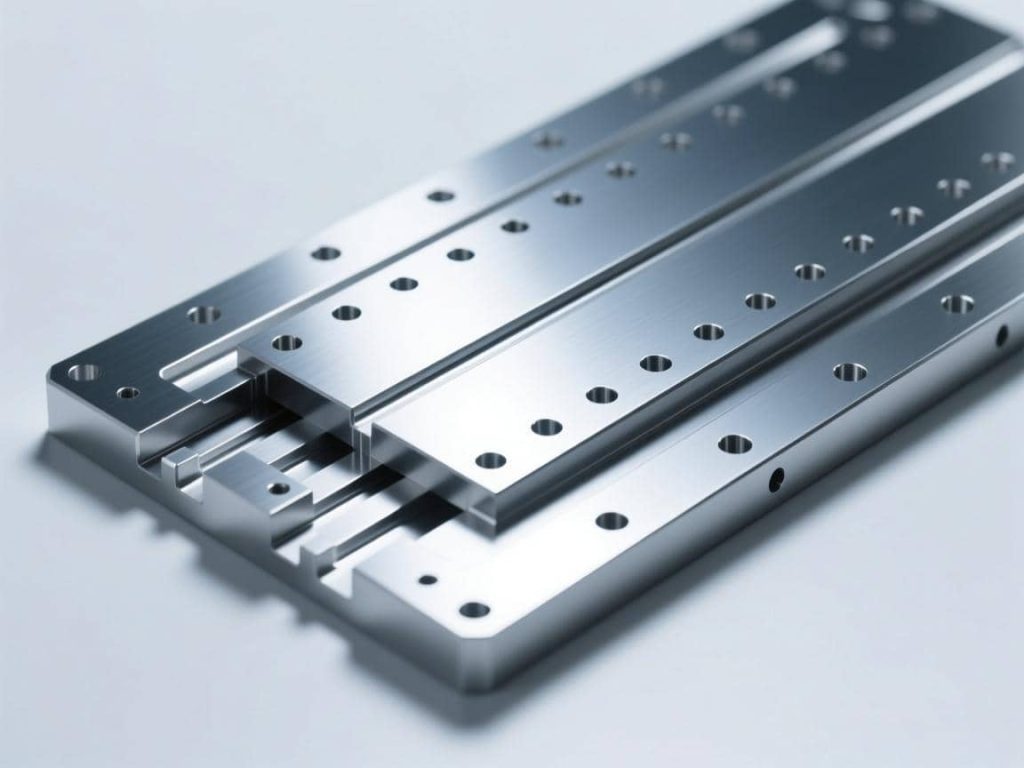

Precision manufacturing requires materials with excellent dimensional stability, flatness, and low internal stress. Thus, in the accuracy-controlled areas like CNC machining, it is even the slightest material distortion may cause extremely expensive errors. Among the preferred materials of the manufacturers, MIC 6 aluminum, along with MIC 6 aluminum plate, have been the most important ones, mainly because of the distinctive properties of flatness machining and stability. How the rise of the MIC 6 cast aluminum tooling plate has come to dominate the markets, what the main features of this plate are, what the applications and market trends are, and why it is still the first choice in precision manufacturing – All these aspects will be dealt with in this article.

Key Characteristics of MIC 6 Aluminum

MIC 6 aluminum is a plate of cast tooling used for high-quality engineering and machining applications. It is a product of a continuous casting process and can have the following properties:

- Flatness & Dimensional Stability: Very low chance of warping during machining because of the uniform thickness and flatness features of MIC 6 plate.

- Low residual stress: Unlike rolled aluminum, MIC 6 cast aluminum tooling plate is a product with the least possible internal stress, hence, ideal for precision applications.

- Machinability: MIC 6’s constant microstructure permits high-speed CNC milling, drilling, and finishing with little damage to the tool.

- Durability: MIC 6 aluminum is the strongest but still lightweight material, which makes it the best choice for light blocking, supporting, and building material purposes.

Compared to the general aluminum tooling plate, MIC 6 aluminum is the preferred choice for areas that require high-quality precision work, primarily because of its superior flatness and stability characteristics.

Common Applications of MIC 6 Cast Aluminum Tooling Plate in CNC and Precision Engineering

MIC 6 aluminum plate has a broad range of applications in precision manufacturing:

| Application Area | Key Benefits | Typical MIC 6 Plate Specification |

| CNC Worktables & Fixtures | Minimal warping under machining loads | 0.5″–6″ thickness, flatness ±0.002″ |

| Precision Measurement Bases | Ensures accurate alignment for instruments | Custom sizes up to 48″ x 120″ |

| Aerospace Components | Stable platform for high-accuracy assembly | High-grade MIC 6 aluminum plate |

| Automotive & Jigs | Supports repeatable, high-volume production | Pre-hardened, stress-relieved aluminum tooling plate |

Among these cases, MIC 6 cast aluminum tooling plate does better than a standard aluminum tooling plate in offering even and stable plate properties with low stress. It’s the reason why in high precision industries, it is an indispensable material.

MIC 6 Aluminum vs Other Aluminum Tooling Plates: Performance and Cost Comparison

While various aluminum tooling plate options exist, MIC 6 aluminum offers unique advantages:

- Enhanced Flatness and Stability: Less prone to warping than rolled or extruded aluminum sheets.

- Superior Machinability: Enables high-speed milling with minimal tool wear.

- Predictable Thermal Response: Maintains dimensional accuracy under varying temperatures.

Comparative Table of Aluminum Tooling Plates:

| Material | Flatness | Stress Relief | Machinability | Cost |

| MIC 6 Cast Aluminum Tooling Plate | ±0.002″/ft | Low | Excellent | Moderate |

| Standard Aluminum Plate | ±0.010″/ft | Medium | Good | Lower |

| Rolled Aluminum Plate | ±0.005″/ft | Medium | Fair | Moderate |

This comparison highlights why MIC 6 aluminum plate is favored in precision-critical applications.

Market Demand and Supply Trends for MIC 6 Aluminum Plate in Global Manufacturing

The worldwide requirements for MIC 6 aluminum plate have been on a continuous uptrend, spurred by the growth in CNC machining, aerospace, and automotive sectors. Here are the most recent developments:

- Increased demand for tailor-made sizes: Manufacturers are asking for plates with specific dimensions and thicknesses for the particular applications they need.

- Fluctuations in supply: Certain areas have not always had enough MIC 6 aluminum available, which, in turn, triggered the search for replacement materials.

- The shift to quality tooling materials: Manufacturers are taking a stand on the quality and durability of the tools and equipment, opting for higher-cost but more enduring materials.

With the exception of the lack of availability of MIC 6 tooling plates once in a while, these are still easy to find throughout a wide area, and their advantages also warrant long-lasting investments for accurate manufacturing processes.

Future of Precision Manufacturing and the Growing Role of MIC 6 Aluminum Tooling Plate

Emerging trends in manufacturing further reinforce the value of MIC 6 aluminum plate:

- CNC Automation: High-speed multi-axis CNC machining relies on plates with low deformation under cutting forces.

- Laser and Additive Manufacturing Integration: MIC 6 aluminum provides a stable base for hybrid manufacturing setups.

- Lightweight and High-Precision Applications: Automotive and aerospace sectors increasingly demand materials that combine weight reduction with dimensional accuracy.

As precision manufacturing evolves, the need for MIC 6 aluminum and aluminum tooling plate solutions is expected to grow, reinforcing their role as industry standards.

Precision manufacturing is still being ruled by MIC 6 aluminum, and on top of that by MIC 6 cast aluminum plates because of their being level, having minimal inner tensions, being workable, and having stable dimensions. Manufacturers will gain a lot from these plates, and therefore they cannot be replaced since they are the preferred material for the accuracy cannot be compromised. It is advisable that manufacturers not only consider purchasing the MIC 6 aluminum plates for their immediate machining needs but also think of them as a strategic investment for their future precision manufacturing requirements.

FAQs

Q1: What is the difference between MIC 6 aluminum and standard aluminum tooling plate?

A1: MIC 6 aluminum offers superior flatness, low stress, and high machinability compared to standard aluminum tooling plate.

Q2: Which applications are best suited for MIC 6 cast aluminum tooling plate?

A2: CNC fixtures, measurement bases, aerospace assembly, and automotive jigs benefit most from MIC 6 aluminum plate.

Q3: How to select the right thickness of MIC 6 aluminum plate?

A3: Thickness depends on load, size, and machining requirements; standard ranges are 0.5″–6″ with custom sizes available.