6063-T5 Aluminum Heat Sink

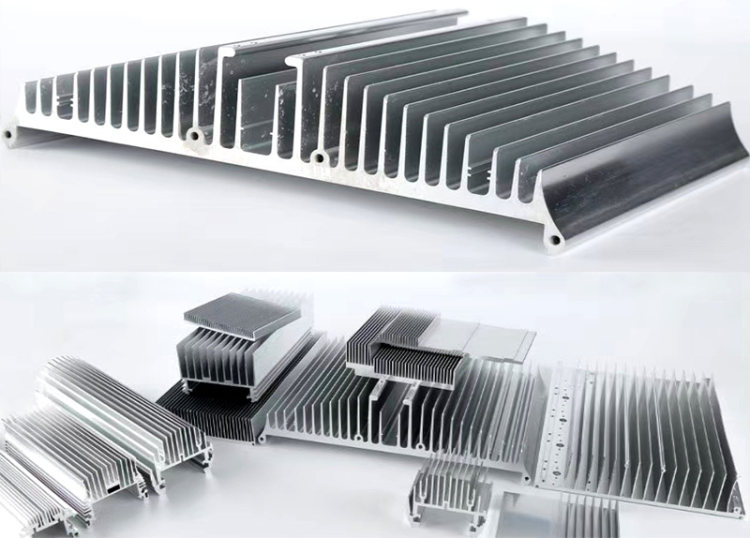

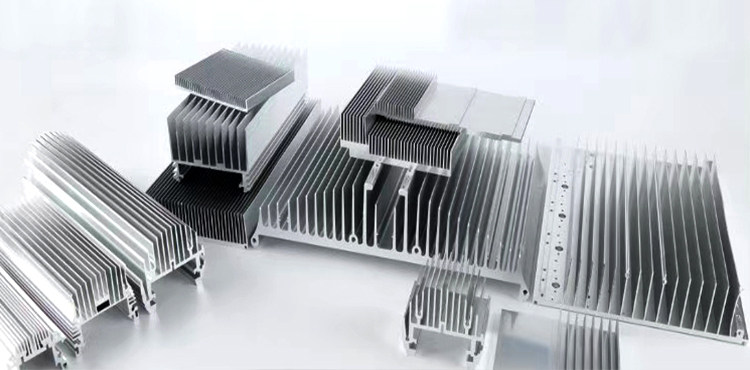

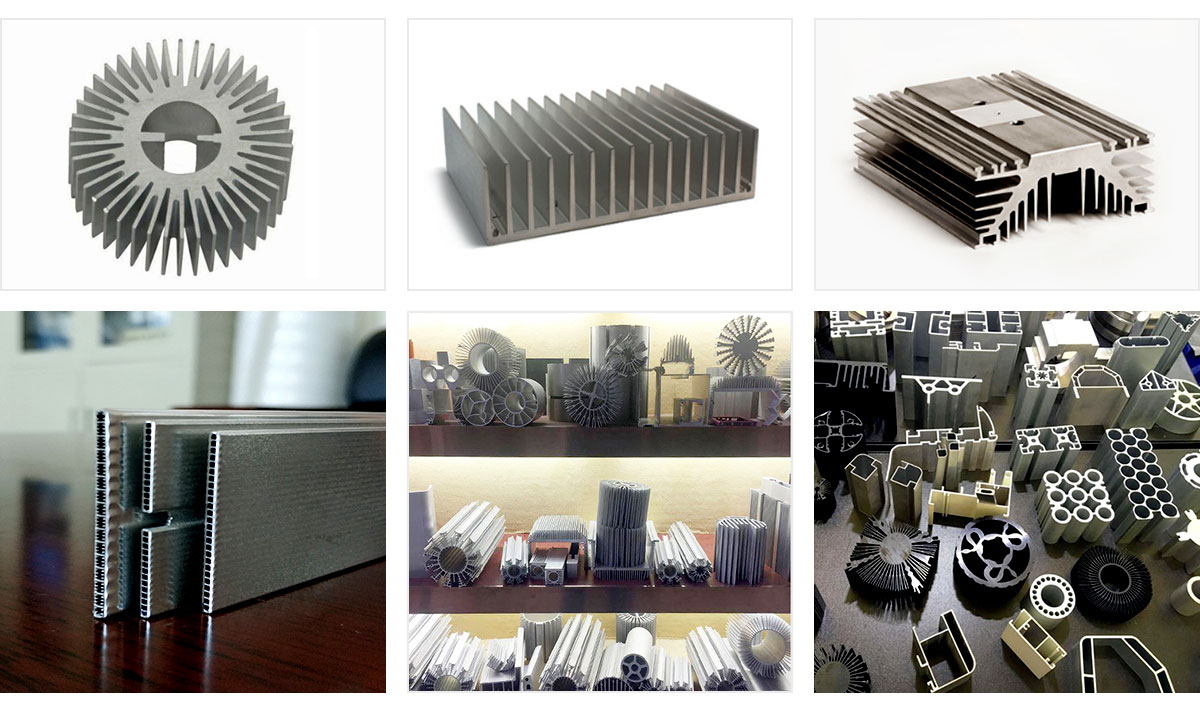

The 6063-T5 aluminum heat sink is a type of heat transfer component that absorb and dissipate the heat from electronic or mechanical devices, helping to keep that device at the proper temperature. It is widely used in industrial and commercial electronic devices. CHAL is one of the most famous heat sinks manufacturers in China, we keep improving aluminum extrusion profile technology and making it possible to produce high-performance aluminum heat sinks for cooling mechanisms. Aluminum heat sinks are designed to maximize the surface area in contact with the coolant fluid and cool air. and that needs a combination of greater strength and lighter weight, aluminum extruded heat sink makes it with a thinner thickness, a narrow tolerance, and higher thermal conductivity.

CHAL is an expert in standard and custom-designed aluminum heat sinks, offering customers a full service from design to production, technical support, fast delivery, and providing a wide selection of high-quality products readily available in stock, at the most competitive prices.

Product Detail of 6063-T5 Aluminum Heat Sink

Alloy

1100, 3003, 6061, 6063

Temper

O/F/H/T5/T6

Standard

ASTM /GM

Characteristics of 6063-T5 Aluminum Heat Sink

lightweight, corrosion-resistant, and excellent heat transfer performance

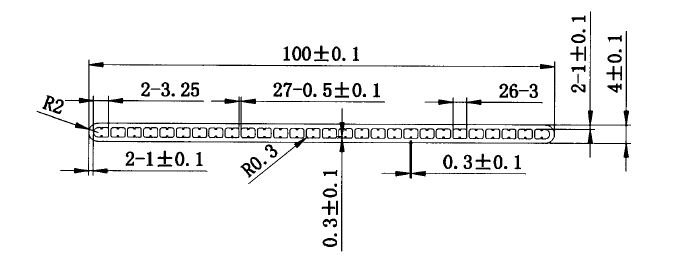

Specifications of 6063-T5 Aluminum Heat Sink

As per the customer’s drawing, for stock specifications, please contact us to get the product list.

| Fins | Width (mm) | Thickness (mm) |

| 10-100 | 8-460 | 0.25mm – 10mm |

Applications of 6063-T5 Aluminum Heat Sink

The aluminum heat sink is commonly used in the following situations:

- LED Lighting

- Central processing units (Computers, TV)

- Motor

- Transistors, Lasers

- Forced Air Heating and Cooling

- Solar Thermal Systems

- Other electronic equipment

Why Choose Aluminum As The Most Common Material For Heat Sinks?

Aluminum is the most common material for heat sinks. In particular, extruded aluminum heat sinks fit the needs of most heat transfer projects.

- Aluminium alloys are the most common material for producing aluminum heat sinks. This is because aluminum costs less than copper, and it is lightweight. So that can save some material costs. Aluminum is also a cost-effective alternative for vast industrial applications.

- Aluminum alloy has relatively good thermal conductivity. Thermal conductivity measures the ability of a metal to conduct heat. This property is a key feature to be considered of the heat sink, you can see from the below table, aluminum and copper have high thermal conductivity, while steel and bronze have lower heat conductivity. Aluminum alloy 1050A has one of the higher thermal conductivity values at 229 W/m•K but is mechanically soft. Aluminum alloys 6060 and 6063 are commonly used, with thermal conductivity values of 166 and 201 W/m•K, respectively. The values depend on the temper of the alloy. Also, for pure metals, thermal conductivity stays roughly the same with increases in temperature. However, in alloys, the thermal conductivity increases with temperature.

| Metal | Thermal Conductivity [BTU/(hr·ft⋅°F)] |

| Copper | 223 |

| Aluminium | 118 |

| Brass | 64 |

| Steel | 17 |

| Bronze | 15 |

- Aluminum alloy has good formability, so that easy to fabricate. Extruded aluminum heat sinks can be made with several channels or fins that increase heat transfer through a higher surface-per-volume ratio.

- Aluminum alloy has good corrosion-resistant and is an excellent choice wherever strength is required.

- Aluminum has a higher strength-to-weight ratio than steel, brass, or copper.

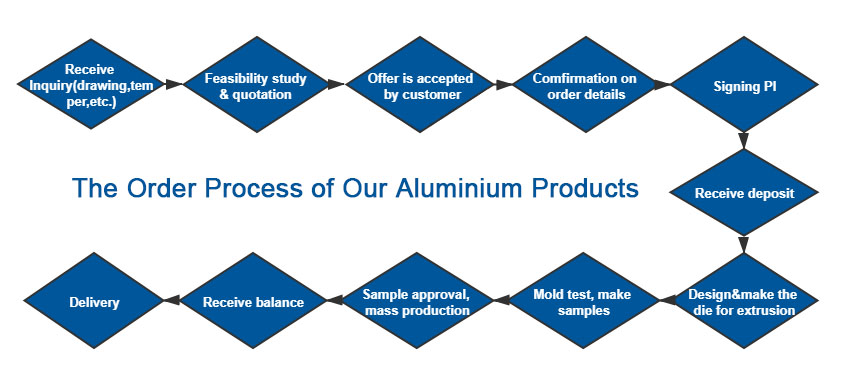

Order Process of 6063-T5 Aluminum Heat Sink