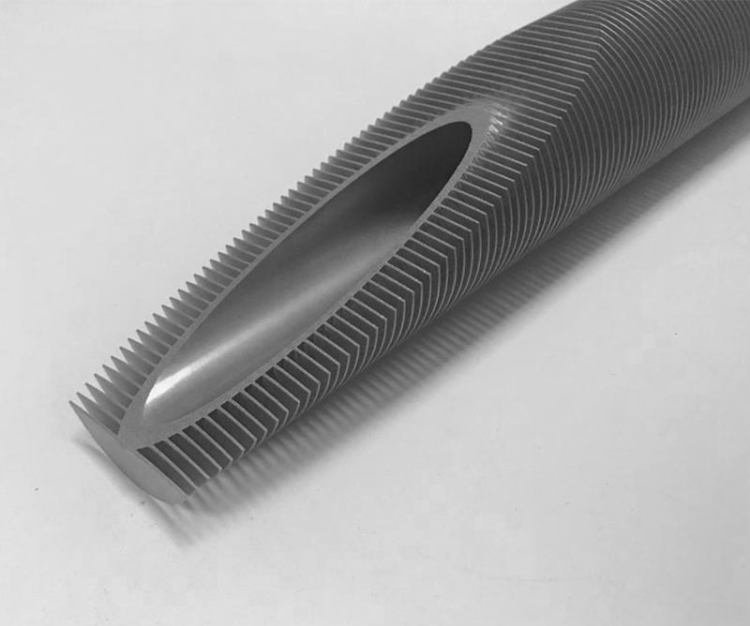

Aluminum Finned Tube

- Aluminum finned tube refers to a kind of heat exchange device. To improve heat exchange efficiency, fins are usually added to the surface of the core tube to increase the outer surface area (or inner surface area).

- The aluminium finned tube is a new, wear-resistant and efficient heat exchange material. It is a high-efficiency and energy-saving heat exchange element, which has the characteristics of high heat exchange efficiency, large heat dissipation area, long service life, wide temperature range and high-pressure adaption.

- CHAL provides a full range of finned tubes for heat exchangers with reliable quality, high performance, complete designs and competitive prices.

Specifications of Aluminum Finned Tube

| Fin Material | Aluminum 1050/1060/1070/1100/5052/6063 |

| Fin Type | Solid or serrated or as per your drawing |

| Fin Pitch | Min. 1.5mm |

| Fins Per Pitch(Density) | 4-12 |

| Fin Segments | 12, 16, 24 fins or as per your design |

| Fin Height | Max. 16.5mm |

| Fin Thickness | 0.4mm Average |

| Core Tube Material | Aluminum alloy (Core tube with extremely thin wall materials can be applied) |

| Base Tube OD | Max 2”(50.8mm) |

| Tube Wall Thickness | No Limit |

| Tube length | No limit |

| Accessories | Tube Support Box, Clamp & Spacer Box |

| Packaging Details | (1) Steel frame case sealed by plywood with each end capped. (2) Solid fumigated wooden box with each end capped. |

All dimensions of aluminum finned tube in inches and specifications upon your request.

| Tube OD | Fin Height | Fin Thickness | Fins per Pitch(Density) |

| 5/8 | 3/8, 1/2 | .015/.016/.020 | 4, 5, 6, 7, 8, 9, 10, 11, 12 |

| 3/4 | 3/8, 1/2, 5/8 | .015/.016/.020 | 4, 5, 6, 7, 8, 9, 10, 11, 12 |

| 1 | 3/8, 1/2, 5/8 | .015/.016/.020 | 4, 5, 6, 7, 8, 9, 10, 11 |

| 1 1/4 | 3/8, 1/2, 5/8 | .015/.016/.020 | 4, 5, 6, 7, 8, 9, 10, |

| 1 1/2 | 3/8, 1/2, 5/8 | .015/.016/.020 | 4, 5, 6, 7, 8, 9, 10, 11 |

| 1 3/4 | 3/8, 1/2, 5/8 | .015/.016/.020 | 4, 5, 6, 7, 8, 9, 10 |

| 2 | 3/8, 1/2, 5/8 | .015/.016/.020 | 4, 5, 6, 7, 8, 9, 10 |

Features of Aluminum Finned Tube

1. Good Corrosion Resistance

Under serious conditions, the oxide materials from aluminum are non-toxic. For heat exchange, no need to worry that air or liquid inside will be destructed by oxide even for a long time.

2. Low Density

By treatment as alloying or heat, it can be used as the structure of construction steel. Feasible for various transportation, especially for small vehicles to reduce weight and consumption.

3. High Yielding and Resistance to Die-cutting

It is easy to process and form.

4. Good Thermal Conductivity

Specially compatible with radiating fins, heat transfer condensers and evaporators.

As a professional finned tube manufacturer, one of our leading products is aluminum finned tube. If you are interested in our products, please do not hesitate to contact us.

Advantages of Aluminum Finned Tube

- Finned tube has compact structure, easy and economical to install. It reduces the joints compared to bare tubes, making installation more quick and cost-saving, reducing the possibility of water leaking at the connection.

- Simple for maintenance, you basically don’t need to maintain finned tubes after installation.

- High efficiency, the finned tube is in full contact with the fin and aluminum pipe, the heat dissipation area is more than 7-8 times that of the bare tube, the inside is smoother, and the internal water flow resistance is small.

- Long service life, the high mechanical strength of the combination of fins and pipes. The tensile strength is above 200Mpa.

- Stable heat transfer performance. It has few temperature fluctuations, and reduces the high-temperature corrosion and over-temperature damage to the metal surface.

- Widely adaptable for heat exchange between air-air, air-liquid, liquid-liquid and various fluids.

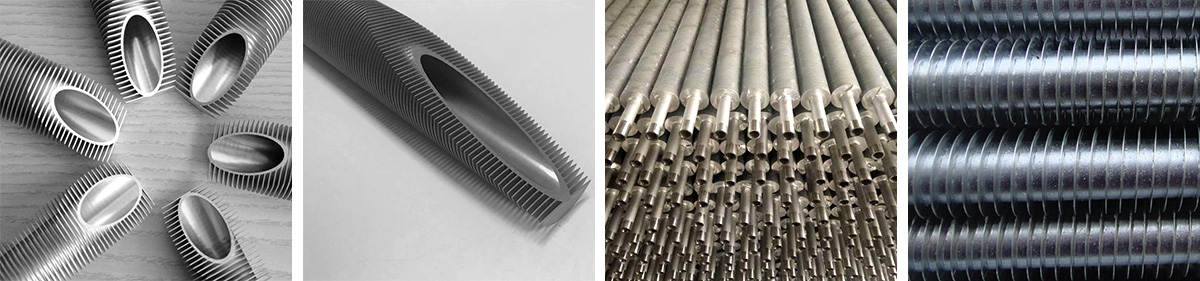

Categories of aluminum finned tubes in different process technology and shapes

- High frequency welded finned tube (high frequency welded open-tooth finned tube)

- Square-finned tube (H-type finned tube)

- Needle tube (nailhead tube)

- Laser welded finned tubes

- Inlaid finned tube

1) G-type finned tube(Embedded finned tube)

2) KL embossed wound finned tube

3) L wound finned tube - DR extruded high finned tube (solid and serrated fins)

- Low-finned tube

- Threaded tube

- Wave joint tube

Applications of Aluminum Finned Tube

- Heat exchanger

- Air conditioner

- Air cooler

- Condenser

- Evaporators

- Food processing

- Refrigeration industries

- Economizer

- Preheater

- Industrial boiler

- Gas turbines

- Refining

- Petrochemical industries

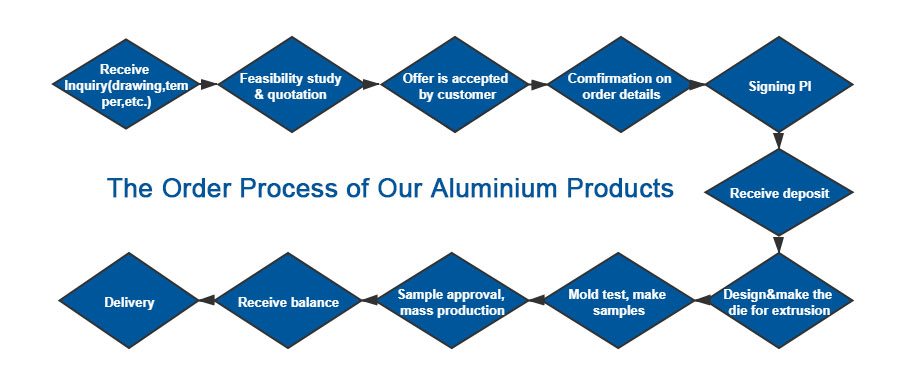

The Order Process of Aluminum Finned Tube

Why Use Aluminum Finned Tube?

Based on the heat exchange application, there are many kinds of materials, and which are Aluminum, Alloy, Copper, Brass, Stainless Steel, Titanium, Carbon Steel, Nickel, etc, while among them, the prominent one is aluminum, and it’s commonly used.

The fundamental uses of finned tube heat exchange should be good solderability and better mechanical strength, formability, good corrosion resistance and thermal conductivity. Aside from these, aluminum and alloy also have good advantages as in extension and higher tensile strength increases under lower temperatures. All around the world, especially for places that are always at low temperatures and compact heat exchange, aluminium finned tubes are widely applied.

China Aluminum Finned Tube Supplier – CHAL

CHAL is professional in manufacturing and supplying various kinds of aluminum finned tubes with superior quality. Our products passed through third-party inspection: SGS, ABS, LLOYDS, MOODY.

CHAL has innovative technology for research and development, strong production capacity and a strict QC system, making us an industry leader.