Extruded Aluminum Tube

- CHAL Aluminium Corporation provides various extruded aluminum tubes/pipes. Both seamless tubes and structural tubes are manufactured with high precision and extremely low tolerance to meet the customer’s specific requirements.

- Standard inventory sizes and customized specifications are available on inquiry.

Extruded Aluminium Tube/Pipe Introduction

Extruded Aluminium Tube/Pipe is formed by hot extrusion. Extrusion is defined as the process of shaping material, by forcing heated aluminium billet to extrude through a shaped opening in a die, combining the differences in die and processing. Extruded tube is available as a seamless or structural grade product.

● Seamless tube is extruded over a mandrel utilizing a hollow billet and is the only tubular product recommended for pressure applications.

● The structural tube is extruded over a bridge or porthole die and will contain weld seams that are evident if anodized.

Extruded Aluminum Tube/Pipe, as a widely used aluminum profile type, aluminium tubes are available in square, rectangular, and round shapes in a range of sizes based on the outside dimensions. For customers, the tube’s strength is a very important factor to consider, which is determined by selected aluminum alloy, the thickness of the walls, and the size of the tube.

The Specification of Extruded Aluminium Tube/Pipe (Structural)

Aluminum tubes are available in square, rectangular and round shapes in a range of sizes based on the outside dimensions.

1. Extruded Aluminum Round Tube

| Size Range OD (mm) | Wall Thickness (mm) |

| 8-150mm | 0.5-20mm |

|

Pipe Size Designation |

Schedule Number |

Outside Dia (inches) |

Inside Dia. (inches) |

Approx.Wt. (Ibs./lineal ft.) |

|

1/2 |

40 |

0.84 |

0.622 |

0.294 |

|

80 |

0.84 |

0.546 |

0.376 |

|

|

3/4 |

40 |

1.05 |

0.824 |

0.391 |

|

80 |

1.05 |

0.742 |

0.51 |

|

|

1 |

40 |

1.315 |

1.049 |

0.581 |

|

80 |

1.315 |

0.957 |

0.751 |

|

|

1–1/4 |

40 |

1.66 |

1.38 |

0.786 |

|

80 |

1.66 |

1.278 |

1.037 |

|

|

1–1/2 |

40 |

1.9 |

1.61 |

0.94 |

|

80 |

1.9 |

1.5 |

1.256 |

|

|

2 |

10 |

2.375 |

2.157 |

0.913 |

|

40 |

2.375 |

2.067 |

1.264 |

|

|

80 |

2.375 |

1.939 |

1.737 |

|

|

2–1/2 |

40 |

2.875 |

2.469 |

2.004 |

|

80 |

2.875 |

2.323 |

2.65 |

|

|

3 |

40 |

3.5 |

3.068 |

2.621 |

|

80 |

3.5 |

2.9 |

3.547 |

|

|

3–1/2 |

40 |

4 |

3.548 |

3.151 |

|

80 |

4 |

3.364 |

4.326 |

|

|

4 |

40 |

4.5 |

4.026 |

3.733 |

|

80 |

4.5 |

3.826 |

5.183 |

|

|

5 |

40 |

5.563 |

5.047 |

5.057 |

|

80 |

5.563 |

4.813 |

7.188 |

|

|

6 |

40 |

6.625 |

6.065 |

6.564 |

|

80 |

6.625 |

5.761 |

9.884 |

|

|

8 |

40 |

8.625 |

7.981 |

9.878 |

|

80 |

8.625 |

7.625 |

15.01 |

|

|

10 |

40 |

10.75 |

10.02 |

14.004 |

2. Extruded Aluminum Square Tube

| Size Range OD (mm) | Wall Thickness (mm) |

| 8-150mm | 0.5-20mm |

| Size O.D.*(inches) | Nominal Wall Thickness | Approx.Wt. (Ibs./lineal ft.) |

| 3/4 | .062 | .201 |

| 3/4 | .125 | .368 |

| 1 | .062 | .271 |

| 1 | .125 | .515 |

| 1-1/4 | .065 | .343 |

| 1-1/4 | .125 | .654 |

| 1-1/2 | .062 | .420 |

| 1-1/2 | .125 | .809 |

| 1-1/2 | .188 | 1.161 |

| 1-3/4 | .125 | .955 |

| 2 | .125 | 1.126 |

| 2 | .188 | 1.598 |

| 2 | .250 | 2.058 |

| 2-1/2 | .125 | 1.383 |

| 2-1/2 | .188.250 | 2.646 |

| 2-3/4 | .188 | 2.266 |

| 3 | 0.125 | 1.691 |

| 3 | 0.188 | 2.487 |

| 3 | .250 | 3.234 |

| 3-1/2 | .125 | 1.984 |

| 4 | .125 | 2.279 |

| 4 | .250 | 4.410 |

| 4 | .375 | 6.395 |

| 4 | .500 | 8.232 |

| 6 | .125 | 3.455 |

3. Extruded Aluminum Rectangular Tube

| Size Range OD (mm) | ||

| Width | Height | Wall Thickness (mm) |

| 10-220 | 1-120 | 0.5-20mm |

| Size O.D.*(inches) | Nominal Wall Thickness | Approx.Wt. (Ibs./lineal ft.) |

| 1/2 x1 | .125 | .367 |

| 3/4×1-1/2 | .125 | .588 |

| 1×1*1/2 | .125 | .661 |

| 1×2 | .062 | .428 |

| 1×2 | .125 | .809 |

| 1×3 | .125 | 1.102 |

| 1×4 | .125 | 1.430 |

| 1-1/4 x 2-1/2 | .125 | 1.029 |

| 1-1/2 x 2 | .125 | .956 |

| 1-1/2 x 2-1/2 | .125 | 1.103 |

| 1-1/2 x3 | .125 | 1.250 |

| 1-1/2 x3 | .187 | 1.824 |

| 1-1/2 x4 | .125 | 1.544 |

| 1-3/4 x3 | .125 | 1.323 |

| 1-3/4 x4 | .125 | 1.617 |

| 2 x 3 | .125 | 1.397 |

| 2 x 3 | .250 | 2.646 |

| 2 x 4 | .125 | 1.690 |

| 2 x 4 | .250 | 3.201 |

| 2 x 5 | .125 | 1.985 |

| 2 x 5 | .188 | 2.929 |

| 2 x 6 | .125 | 3.279 |

| 2 x 6 | .188 | 3.372 |

| 2 x 6 | .250 | 4.410 |

| 2 x 8 | .125 | 2.837 |

| 3 x 4 | .125 | 1.985 |

| 3 x 5 | .125 | 2.279 |

| 3 x 5 | .250 | 4.410 |

| 3 x 6 | .188 | 3.814 |

| 4 x 6 | .188 | 4.256 |

| 4 x 6 | .250 | 5.586 |

| 4 x 6 | .500 | 10.584 |

| 4 x 8 | .250 | 6.762 |

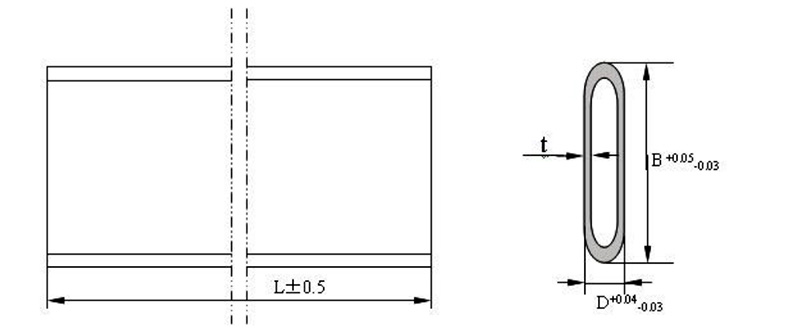

4. Extruded aluminum flat tube

There are two kinds of extruded aluminum flat tubes. One is a hollow flat tube with a single port, another is extruded aluminum multi-port flat tube (know more about aluminum multi-port flat tube).

| Size Range of extruded aluminium flat tube (mm) | |||

| B±0.05 | D ±0.05 | T (wall thickness) | L (length) |

| 10-180 | 5-120 | 0.3-20 | ≤5000 |

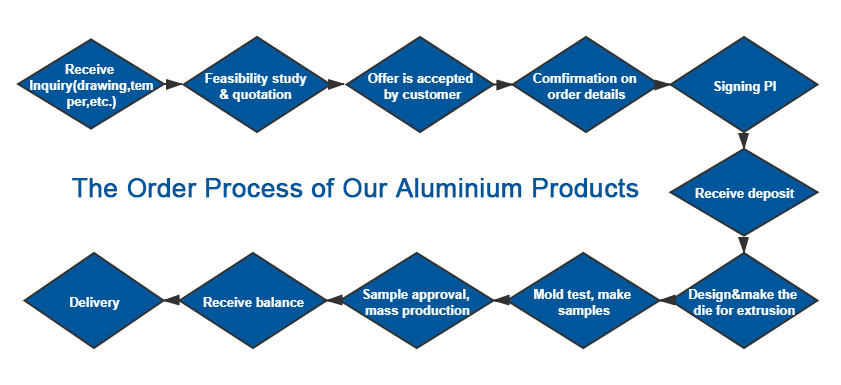

The Order Process of Extruded Aluminum Tube

Options of Aluminium Alloy

| Aluminium Series | Alloy Grade | CHAL Usage Ratio | Recommendation |

| 1XXX | 1050/1060/1100/1197 | 10% | Pure aluminum, Main componentAl≥99% |

| 2XXX | 2011/2017/2024 | 2% | Copper-Aluminium Alloy |

| 3XXX | 3003/3103/3A03/3A21 | 15% | Manganese-Aluminium Alloy |

| 4XXX | 3% | Silicon-Aluminium Alloy | |

| 5XXX | 5049/5052/5083/5086 | 7% | Magnesium-Aluminium Alloy |

| 6XXX | 6005A/6061/6063 | 52% | Magnesium Silicon-Aluminium Alloy |

| 7XXX | 7075 | 7% | Zinc-Aluminium Alloy |

| 9XXX | 9A66/9A52 | 4% | Customized alloy |

Options of Aluminum Temper

| Temper | Description |

| O | Full soft (annealed) |

| F | As fabricated |

| T4 | Solution heat treated and naturally aged |

| T5 | Cooled from hot working and artificially aged (at elevated temperature) |

| T6 | Solution heat treated and artificially aged |

| H11-H18 | Strain hardened |

Customized Solutions of Extruded Aluminum Tube

- Surface treatment: Anodizing, Zinc coating, the Flux coating

- Machining service: CNC bending

Extruded Aluminum VS. Drawn Aluminum

Aluminum is an extremely versatile material. There are many different ways to shape aluminium. Drawn and extruded aluminium are the two main types of aluminum production.

The main difference between extruded aluminum and drawn aluminum is the way the mold forms the aluminum.

Extruded Aluminum

Extruded aluminium is made by heating the aluminum and forcing it through a mold. The shape of the mold determines the appearance of the final product. For example, an “I” mold can make aluminum I-beams. After the product is molded, it is cooled and then stretched to eliminate any distortion during cooling. As it hardens, the aluminum becomes stronger. The hardening process can be done at room temperature, but because this can be time-consuming, most manufacturers use heating Chambers to quickly temper aluminum.

There are two kinds of structural tubes manufactured by the extrusion process. In the first method, the aluminum tube is split and then resealed using high temperature, high pressure, and metallurgical welds. The resulting seams in this process are sometimes visible to the naked eye. In the second process, the tubes are produced by pushing the hollow blank through the mold, which has no seams.

Drawn Aluminum

The aluminum is drawn into the mold and undergoes plastic deformation. Determining the flexibility or plasticity of aluminum is a key part of this process because aluminum cannot be stretched to the point where it becomes brittle or torn.

Our high-precision drawn aluminum tubes are widely used for heat exchangers, including aluminum round tube, internal thread tube, seamless collector tube, old drawn aluminium tube, seamless drawn aluminium tube, capillary tube, peanut tube, etc. It is the key material for terminal products, such as home and commercial air conditioning evaporator and condenser, automobile air conditioning evaporator, radiator condenser, water tank, etc.

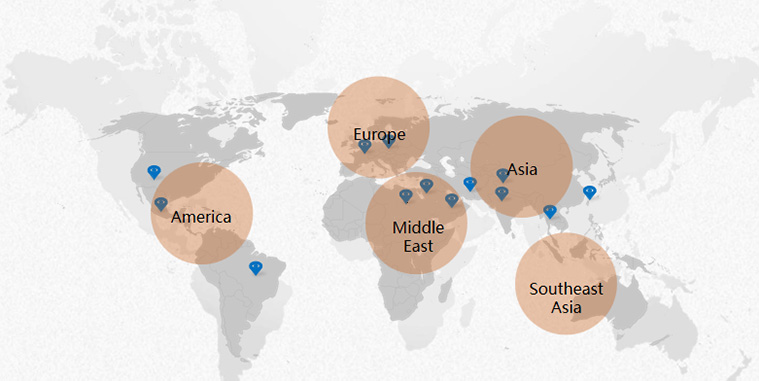

Marketing – Overseas

Almost 20% of products are exported to Southeast Asia, Middle East, America, etc, more than thirteen countries and regions.

Our Customers

Research and Development

CHAL Aluminium corporation focuses on research and development, we work with a famous academic institution and industrial association. Our researchers and academic partners take part in business development and the technical development of the products and processes. We work to move boundaries of how aluminum is used. We develop design solutions that benefit from the properties of aluminum both technically and economically. CHAL Aluminium Group has 5 R/D centers across the nation.

- High-Performance Aluminium Alloy R/D Center(Chongqing)

- High-Performance Aluminum Sheet and Foil R/D Center(Beijing)

- Refrigeration and Heat Exchange R/D Center(Shanghai)

- Aluminium Magnesium Alloy R/D Center(Zhengzhou)

- Advanced Mould R/D Center(Zhengzhou)

Shanghai Refrigeration and Heat Exchange R/D Center is specialized in designing and researching aluminum products for commercial air conditioning & car air conditioning systems, including various extruded aluminum tube, aluminum micro-channel tube (MPE), drawn aluminium tube and drawn profiles, aluminum header pipe, welded tube for condenser and radiator, etc.

Production Process Diagram

The manufacturing process, which includes extrusion, cold drawing, annealing, rolling, and cutting, guarantees narrow tolerance, and a superior surface finish of the tubes.

Production Equipment

1. Aluminium Billet Cast Equipment (Germany)

2. Extruder: 1650T/1800T/2000T/2600T/3600T

3. Metallisation Zinc Spray System (UK)

4. Pre-Flux/Si-flux Coating Line

5. Fixed Length Cutting Machine (Korea & Japan)