Aluminum Condenser Header Pipe

The aluminum condenser header pipe also called aluminum condenser manifold, which is one of the important parts of HVAC systems. The primary usage is to uniformly distribute coolant of pipe circuits in air coolers, dry coolers, evaporators, and condensers to avoid creating temperature layers in the passing air stream. The header consists of an oversized pipe, which ensures speed and pressure are so small as to have a negligent effect on the inlet resistance in the individual circuits. The fluorine in the air conditioner is compressed by the compressor to produce high-temperature and high-pressure liquefied gas, which is condensed by the condenser and then becomes a low-temperature and high-pressure liquid, and enters the collector tube.

Details of Aluminum Condenser Header Pipe

- Cladding type: Single side cladding material, double sides cladding material.

- Cladding layers: 4045, 4343, 4043, 7072, and other anti-corrosion layers, can be added with zinc as needed.

- Material temper: M, H14, H16, H18, or according to customer requirements.

- Cladding rate: 10±2 or according to customer requirements.

- Core layer: 3003, 3305, 6063, etc.

- Outer diameter: 9-61mm.

- Wall thickness: 1-3.0mm.

- Processing: High-frequency welding.

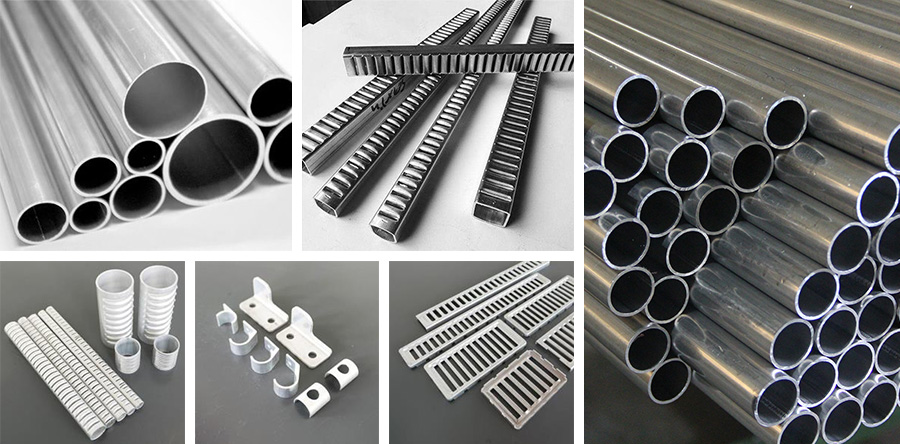

Types of Aluminum Condenser Header Pipe

- Cladding Aluminum Condenser Header Pipe

- Punched Aluminum Condenser Header Pipe

Specifications of Aluminum Condenser Header Pipe

Round Aluminum Condenser Header Pipe

| Size | Code | Drawing No. | Dimensions | ||

| T Width | Thickness | Material Thickness | |||

| P20x1.15 | P01-20×1.15A | P20x1.15-01A | 20±0.1 | 17.7±0.1 | 1.15 |

| P20x1.2 | P01-20×1.2B | P20x1.2-01B | 20±0.1 | 17.6±0.1 | 1.2 |

| P20x1.5 | P01-20×1.5C | P20x1.5-01C | 20±0.1 | 17±0.1 | 1.5 |

| P20x1.12 | P01-20×1.12D | P20x1.12-01D | 20±0.1 | 17.76±0.1 | 1.12 |

| P20x1.0 | P01-20×1.0E | P20x1.0-01E | 20±0.05 | 18±0.05 | 1.0 |

| P20x2.05 | P01-20×2.05F | P20x2.05-01F | 20±0.05 | 16±0.05 | 2.05 |

| P28x1.6 | P02-28×1.6A | P28x1.6-02A | 28±0.12 | 24.8±0.12 | 1.6 |

| P28x1.5 | P02-28×1.5C | P28x1.5-02C | 28±0.1 | 25±0.1 | 1.0 |

| P33.4×1.5 | P03-33.4×1.5A | P33.4×1.5-03A | 33.40-0.2 | 30.40-0.2 | 1.5 |

| P30x1.2 | P04-30×1.2A | P30x1.2-04A | 30+0.20 | 27.6+0.20 | 1.2 |

| P30x1.5 | P04-30×1.5B | P30x1.5-04B | 30±0.05 | 27±0.05 | 1.5 |

| P30x1.6 | P04-30×1.6C | P30x1.6-04C | 30±0.12 | 26.8±0.1 | 1.6 |

| P19x1.3 | P05-19×1.3A | P19x1.3-05A | 19±0.05 | 16.4±0.05 | 1.3 |

| P19x1.2 | P05-19×1.2B | P19x1.2-05B | 19±0.05 | 16.6±0.05 | 1.2 |

| P15.88×1 | P06-15.88x1A | P15.88×1-06 | 15.88±0.05 | 13.88±0.05 | 1 |

| P31.6×1.5 | P07-31.6×1.5A | P31.6×1.5-07 | 31.6±0.2 | 28.60-0.1 | 1.5 |

| P25x1.8 | P08-25×1.8B | P25x1.8-08B | 25±0.1 | 21.4±0.1 | 1.8 |

| P25x1.5 | P08-25×1.5C | P25x1.5-08C | 25±0.1 | 22±0.1 | 1.5 |

| P38x2 | P09-38x2A | P38x2-09A | 38±0.15 | 34±0.1 | 2 |

| P38x2.2 | P09-38×2.2B | P38x2.2-09B | 38±0.15 | 33.6±0.1 | 2.2 |

| P22x1.3 | P10-22×1.3A | P22x1.3-10A | 22±0.075 | 19.4±0.075 | 1.3 |

| P22x1.27 | P10-22×1.27B | P22x1.27-10B | 22±0.05 | 19.46±0.05 | 1.27 |

| P26x1.9 | P11-26×1.9A | P26x1.9-11A | 26±0.15 | 22.2±0.15 | 1.9 |

| P23x1.7 | P12-23×1.7A | P23x1.7-12A | 23±0.1 | 19.6±0.1 | 1.7 |

| P22.28×0.6 | P13-22.28×0.6A | P22.28×0.6-13A | 22.28±0.1 | 21.08±0.1 | 0.6 |

| P17.5×1.2 | P14-17.5×1.2A | P17.5×1.2-14A | 17.5±0.1 | 15.1±0.1 | 1.2 |

| P23.2×1.3 | P15-23.2×1.3A | P23.2×1.3-15A | 23.2-23.3 | 20.6-20.7 | 1.3 |

| P27x1.3 | P16-27×1.3A | P27x1.3-16A | 27±0.05 | 24.4±0.05 | 1.3 |

| P16x1 | P17-16x1A | P16x1-17A | 16±0.05 | 14±0.05 | 1 |

| P16x1.2 | P17-16×1.2B | P16x1.2-17B | 16±0.05 | 13.6±0.05 | 1 |

| P15.88×0.6 | P06-15.88×0.6B | P15.88×0.6-06B | 15.88±0.1 | 14.68±0.1 | 0.6 |

| P20.15×1.15 | P18-20.15×1.15A | P20.15×1.15-18A | 20.15±0.05 | 17.85±0.05 | 1.15 |

| P21x2 | P19-21x2A | P21x2-19A | 21±0.05 | 17±0.05 | 2 |

| P20.1×1.25 | P20-20.1×1.25A | P20.1×1.25-20A | 20.1±0.05 | 17.6±0.05 | 1.25 |

| P32x2.5 | P21-32×2.5A | P32x2.5-21A | 32±0.15 | 27±0.15 | 2.5 |

| P32x2.3 | P21-32×2.3C | P32x2.3-21C | 32±0.15 | 27.4±0.15 | 2.3 |

| P32x1.8 | P21-32×1.8B | P32x1.8-21B | 32±0.1 | 28.4±0.1 | 1.8 |

| P30.26×1.55 | P22-30.26×1.55A | P30.26×1.55-22A | 30.26±0.05 | 27.14-27.2 | 1.55 |

| P39.4×2.7 | P23-39.4×2.7A | P39.4×2.7-23A | 39.4±0.15 | 34±0.1 | 2.7 |

| P12x1 | P24-12×1 | P12x1-24A | 12±0.05 | 10±0.05 | 1.0 |

| P33.3×1.5 | P25-33.3×1.5A | P33.3×1.5-25A | 33.3±0.1 | 30.3±0.1 | 1.5 |

| P22.22×1.6 | P26-22.22×1.6A | P22.22×1.6-26A | 22.22±0.05 | 19.02±0.05 | 1.6 |

D-type Aluminum Condenser Header Pipes (Including D and Square Types)

| Size | Code | Drawing No. | Dimensions | ||

| T Width | Thickness | Material Thickness | |||

| PD20.4×18 | PD01-20.4×18 | PD20.4×18-01 | 20.4±0.1 | 18±0.1 | 1.2 |

| PD20x18 | PD02-20×18 | PD20x18-02 | 20±0.1 | 18±0.1 | 1 |

| PD20.4×18.5 | PD03-20.4×18.5 | PD20.4×18.5-03 | 20.4±0.05 | 18.5±0.05 | 1 |

| PD25.5×19 | PD04-25.5×19 | PD25.5×19-04 | 25.5±0.1 | 19±0.05 | 1.2 |

| PD15.1×12.7 | PD05-15.1×12.7 | PD15.1×12.7-05 | 15.1±0.05 | 12.7±0.05 | 1.2 |

CHAL supplies all kinds of precision high frequency welded tubes/pipes. The shape can be round, square, flat, D type, or B type, with stamping processing, round and square tubes are widely used as condenser header pipes, and the flat tube is used as a radiator tube. We not only provide aluminum weld tubes, and also provide stamping service, according to customer drawings, stamping into the final collector tube (aluminum condenser header pipe).

Characteristics of Aluminum Condenser Header Pipe

- Low cost and lightweight

- Easy welding

- Easy to form and bend

- Resistant to low temperatures

- Good corrosion resistance

- Good voltage resistance

- Compliance with standard ROHS

- Small deviation range

- Cost-effective

Applications of Aluminum Condenser Header Pipe

Aluminium condenser header pipe is mainly used in condensers, oil coolers, including:

- Automotive refrigerators

- New energy vehicles

- Home appliance air conditioners

- Construction machinery

- Spacecraft mooring

- Other heat exchanger cores

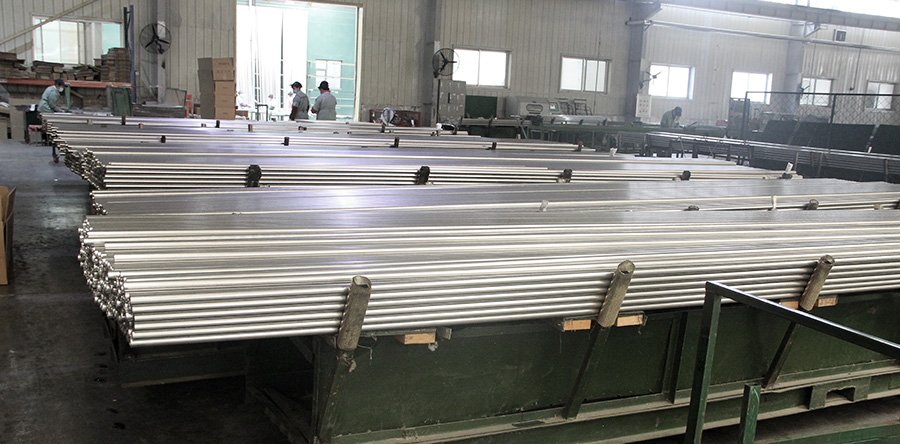

Supply Ability

- 7 tube manufacturing production lines, all of which use imported equipment.

- Over 10, 000 tons of annual production capacity.

- A long-term stable cooperative relationship with many auto parts manufacturers.

- Over 80% of products are for the OEM market.

- About 320 million RMB (50 million USD) of annual sales revenue in 2017.

Packaging & Delivery

- 1-5MT/ pallet, plastic film packing, strong polar fumigation wooden pallet, steel belt fastened outside, seaworthy.

- Port: Shanghai, Qingdao.

- Lead Time: It depends on the quantity, generally within 15 days after the first payment or LC is received.

- Payment Terms: T/T, L/C, Paypal, Western Union.

Company Profile

CHAL Aluminium Corporation is one of the biggest aluminum manufacturers in China. The Heat Transfer Material Division, established in 2000, is a high-tech enterprise specializing in the R&D and marketing of the aluminum heat transfer plate, belt, clad foil, aluminum pipe, condenser header pipe, welding flat tube for radiator and spare parts. With continuously improved technology and scientific management system, we have passed the certification of quality management system ISO/TS16949 of NSF, an internationally recognized certification authority in the USA.

The annual sales volume of the heat transfer materials can reach RMB 500 million and profit tax can reach RMB 40 million. At present, our aluminum radio-frequency welded tubes are widely used in condensers, evaporators, radiators, and intercoolers and widely applied by well-known automobile manufacturers and air conditioner enterprises, such as Volkswagen, GM and Gree, and exported to the USA, Europe, and South Korea.

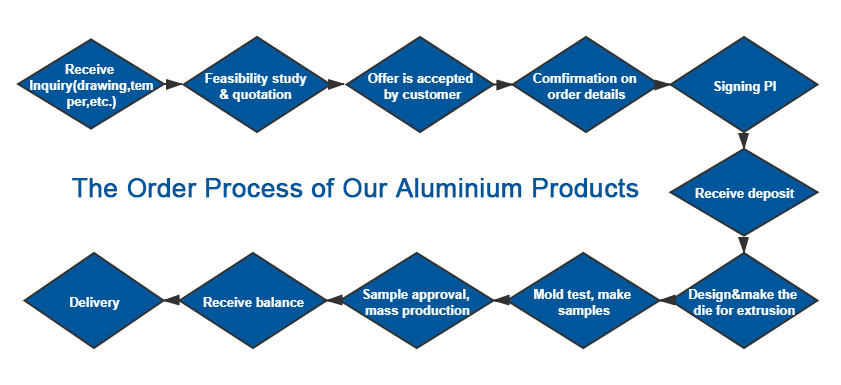

Why Choose Us for Aluminum Condenser Header Pipe?

- We provide service to the whole aluminium industry chain.

- We have 20 years of experience in the extrusion and manufacturing process of aluminum products.

- We have advanced equipment and technology, equipped with a capable team.

- We strictly manage and operate the factory according to ISO9001 standards.

- We have a 550-6800T extruder, which can OEM all kinds of aluminum profiles and aluminum products.

- We can efficiently and quickly OEM your cooling solution to solve the problem of high power heat dissipation.

- We provide customized services.