Bare Aluminum Wire

Bare aluminium wire is developed using aluminum rode to serve matchless quality in various applications such as winding, cabling, and telecommunication. Each bare aluminum wire is fabricated using pure, electrolytic grade, bright annealed bare aluminum with up to 100% conductivity. The conductor is made of multiple strands of finely drawn aluminum wires, thereby offering greater flexibility, which makes these wires ideal for conduit wiring. It is usually used for transformer motors, transformer winding, modern instruments, generators, welding machines,s and so on.

Bare Aluminum Wire Grade:

1100, 1030, 4043, 4048, 7072, 8030, 6201, raw material accepts customization.

Bare Aluminium Wire Supplier

Bare Aluminium Wire has high conductivity and magneto conductivity of copper, high strength of steel, bending and tin’s thermal conductivity, corrosion resistance, and oxidation resistance at high temperatures.

CHAL Aluminium Corporation owns a plant of producing aluminum wire, with sincere intention to preserve and uplift our position as the eminent company. We are offering all kinds of aluminium wires. Such as bare aluminium wires, FeCrAl wires, aluminum flux cored brazing wires, aluminium solder wires, 0.2-8mm enameled aluminum wires, electrical wires, magnesium aluminium wires and aluminium brazing welding wires. The offered wire is manufactured using high quality aluminum and ultra-modern machinery. Our provided wire is widely applauded by our clients for its excellent features such as high strength, high precision and long life. This wire is available in various sizes by the requirement of our precious clients. Available in various thickness dimensions from thick to superfine, these wires can be ordered at the best price in the industry.

Advantages of Bare Aluminium Wire

- Simple structure

- Large transmission capacity

- Good conductivity

- High mechanical strength

- High-temperature resistance

- Corrosion resistance

- Unit volume light

- Easy to set up

- Convenient installation and maintenance

Applications of Bare Aluminium Wire

- This product is suitable for overhead power transmission lines with AC 50Hz at various voltage levels.

- They are suitable for laying across rivers, valleys and places where special geographical features exist.

Specifications of Bare Aluminum Wire

1. Aluminium Wire

| Type | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Main | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 22.5-24.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Chemical composition | Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.0 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 |

| Re | opportune | opportune | opportune | opportune | opportune | opportune | opportune | |

| Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

| Maximal Temperature (°C) | 650 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| Resistivity 20°C (10-6ohm*m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| Density(g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| Thermal conductivity (KJ/m*h*°C) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | |

| Extend strength (a*10-6/°C) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| Melting point ( °C) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| Tensile strength(N/mm2) | 588-735 | 630-780 | 637-780 | 630-780 | 637-784 | 650-800 | 680-830 | |

| Extension rate% | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| Section shrink rate (%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| Repeatedly bending frequency (F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| Specific heat J/g. | 0.49 | 0.494 | 0.52 | 0.46 | 0.49 | 0.494 | 0.494 | |

| Linear expansion coefficient a×10-6/201000 | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| hardness (H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| Rapid life h/ | ≥80/1250 | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1350 | ≥80/1350 | ||

| Microstructure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

| Magnetism | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

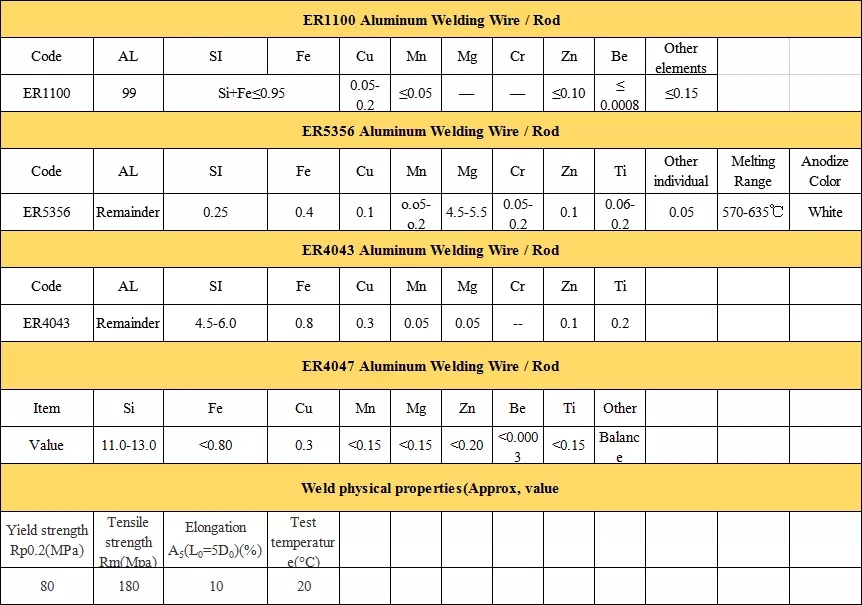

2. Aluminium Rod

| Name of Element | Si | Fe | Cu | V+Ti+Mn+Cr | Other | Al |

| Percentage | ≤0.11 | 0.25 | 0.01 | 0.02 | 0.03 | ≥99.6 |

Note: If the mechanical characteristics and electric characteristics of the aluminum rod are in accordance with the standard, the tests of chemical elements contained may not be included in the final inspection.

Bare Aluminum Wire Tolerance of Diameter

| Diameter | Deviation | Max.Orality |

| Φ9.0-12.0 | +0.5 | 0.9 |

| Φ12.5-20 | +0.7 | 1.2 |

The Quality of Bare Aluminum Wire Surface

- The surface of the aluminum rod should be neat and well-distributed in dimension.

- The surface of the aluminum rod should be clean without wrinkles, wrong roundness, cracks, impurities, twists, and other defects affecting use.

Note: Standard Specifications for Aluminum 1350 Drawing Stock for Electrical Purposes.

Tensile Property of Bare Aluminum Wire

| Temper | Tensile Strength | |

| Ksj | Mpa | |

| 1350-O | 8.5-14.0 | 59-97 |

| 1350-H12 and-H22 | 12.0-17.0 | 83-117 |

| 1350-H14 and-H24 | 15.0-20.0A | 103-138 |

| 1350-H16 and-H26 | 17.0-22.0A | 117-152 |

Resistivity Limits of Bare Aluminum Wire

| Temper | Max.Resistivity(Ω/MM2) | Min.Conductiuity of Equivalent Volume(% IACS) |

| 1350-O | 0.027899 | 61.8 |

| 1350-H12 and-H22 | 0.028035 | 61.5 |

| 1350-H14 and-H24 | 0.028080 | 61.4 |

| 1350-H16 and-H26 |

Supply Ability of Bare Aluminum Wire

5000 Tons per month

Packaging & Delivery

- Packaging: 1-5MT/pallet, plastic film packing, strong polar fumigation wooden pallet, steel belt fastened outside, seaworthy.

- Port: Shanghai, Qingdao.

- Lead Time :It depends on the quantity, generally within 15 days after the first payment or LC received.

- Payment: We accept T/T, L/C, Paypal, Western Union.

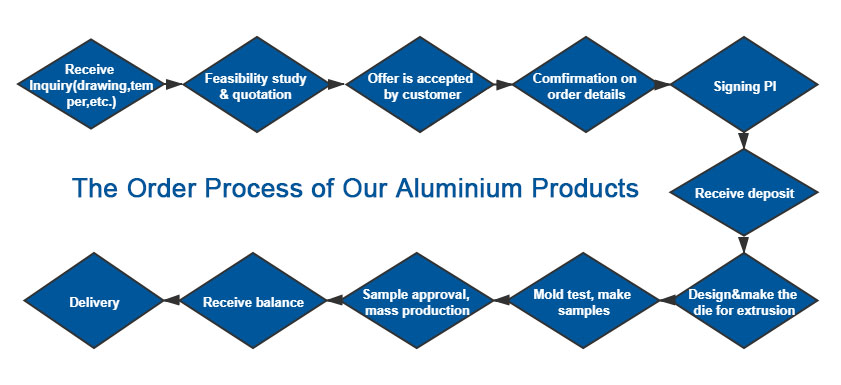

Order Process of Bare Aluminum Wire

Our Service

Product service is the key point between business cooperation, we have our own special services as below:

- Free 3-5 year product warranty.

- We can provide the pre-sale, sale and after-sale instruction and technical support.

- We have the standard wooden drum packing and strict product inspect the process, etc.

| Pre-sale: 1. Provide professional technical support. 2. Confirm product information. | Sale: 1. Product process report. 2. Raw material & cable inspection. 3. Other support. | After-sale: 1. 3 years’ warranty-Free changed. 2. Install technical instructions. |

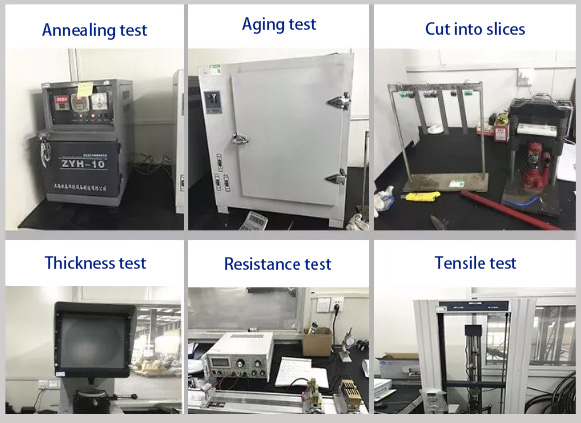

100% product inspection from raw material to finished cables step by step

Company View