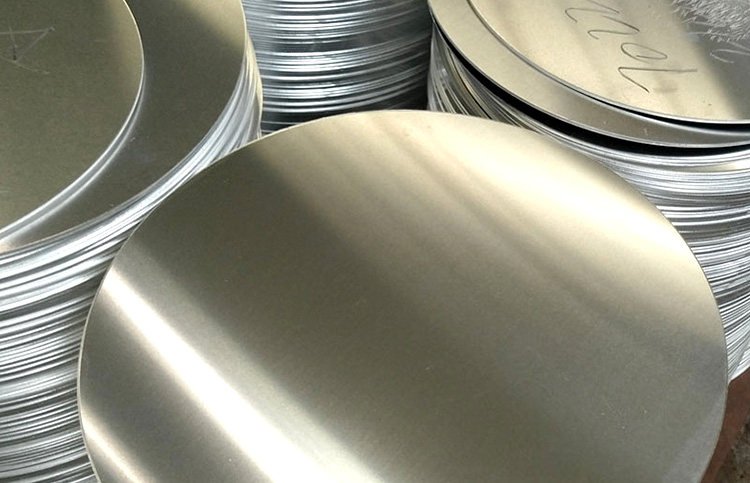

Aluminum Circles/Discs

Aluminum circle is also known as aluminum disc, which is a perfect material for making aluminum round metal. It is usual with thickness from 0.3mm-10mm, and a diameter from 100mm-800mm. It is widely used in electronics, daily chemicals, medicine, culture and education, auto parts, and other industries. Mainly, 1xxx and 3xxx aluminum circles are used for making kitchen utensils, cookware such as non-stick pans, saucepans, pizza pans, pressure cookers, and other hardware such as lampshades, water heater casings, etc. Our aluminum circles are made in accordance with international standards ASTM B209, ASME SB 221, EN573, and EN485.

CHAL Aluminium Corporation focuses on the research and development of aluminum, we cooperate with famous academic institutions and industry associations. Our researchers and academic partners are involved in the business and technology development of aluminum product processing and production. We develop and design solutions to improve the performance of aluminum technically and economically. CHAL Aluminium Group has 5 R&D centers in China.

Aluminum Circles /Discs Details

| Deep drawing aluminum circle/disc 1050, 1060, 1100, 1200, 3003, 3004, 3105, etc. | |||

| Aluminum Alloy | Thickness(mm) | Diameter(mm) | Temper |

| 1050, 1060, 1100 | 0.3-8.0 | 15-1200 | HO, H12, H14, H22, H24 |

| 3003, 3004, 3105 | 0.3-8.0 | 15-1200 | HO, H12, H14, H22, H24 |

| Material process | CC AND DC (DC For cookware and CC for road sign) | ||

| DC for cookware with good deep drawing and spinning | |||

| Further Fabrication | Deep Drawing, Spinning, Anodizing | ||

| Customize size | Size can be produced as per clients requirement | ||

| Surface | Mill finish, or color coated or anodized | ||

| MOQ per size | 3 tons | ||

| Quality Standard | ASTM B209, EN573-1 | ||

| Price terms | FOB, CRF, CIF | ||

| Payment Terms | 30% deposit in advance, 70% balance payment by TT or LC | ||

| Surface | Mill Finish, Plain | ||

| Standard | GB/T, ASTM, EN | ||

| Delivery time | Within 25 days after receipt of the lc or deposit | ||

| Material Quality | Totally free from defects like roll makers, edge damage, oil stain, white rust, dents, scratches, etc. A+++ quality | ||

| Equipment | 6 hot tandem rolling line, 5 cold mill production lines | ||

| Application | DC hot roll for cookware and utensils and CC for road signs | ||

| Packing | Standard export worthy wooden pallets, and standard packing is about 1 ton/pallet. Pallet weight also can be as per client’s requirement, and one 20′ can be loaded about 25mts. | ||

| Loading Port | Any port of China, Shanghai & Ningbo &Qingdao | ||

| Delivery Methods | 1. By sea: Any port in China 2. By train: Chongqing(Yiwu) International Railway to Middle Asia-Europe | ||

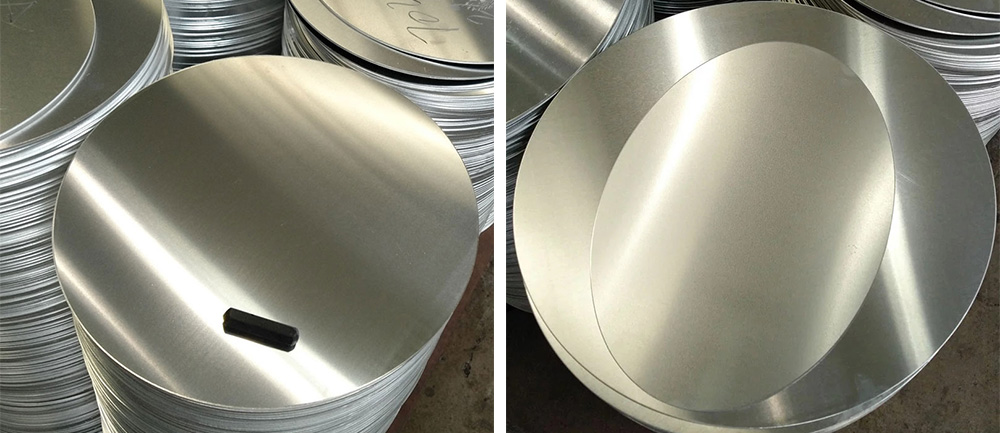

- The aluminium circles (aluminum discs) can be provided with center holes upon request.

- Paper interleave and PE/PVC can be applied upon request.

- Some alloys can be provided as lighting-grade and hard anodize (HA) quality upon request.

- All circles are shipped with material test reports.

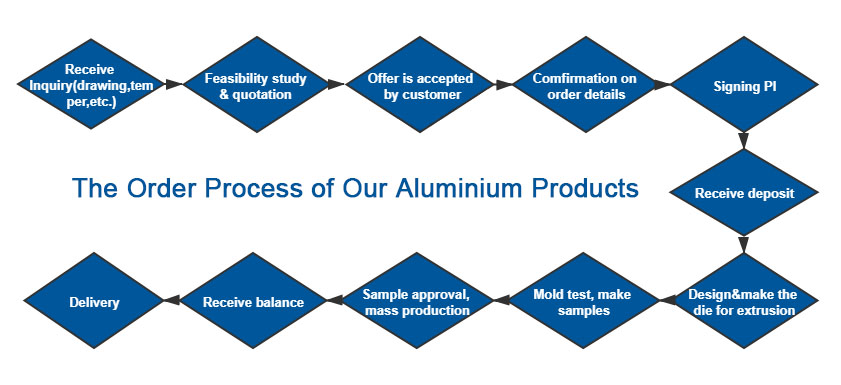

Order Process of Aluminum Circles/Discs

DC Quality of Aluminum Circles

Deep drawing quality, less scrap.

Aluminum circle is suitable for making cookware and the following products:

● Stock pots ● Fry pans ● Tea kettles

● Pressure cookers ● Pizza pans ● Rice cookers

● Restaurant cookware ● Coffee urns ● Electric skillets

CC Quality of Aluminum Circles

Its good surface is suitable for the lighting industry.

Applications of Aluminum Circles:

● Recessed lighting ● High bay industrial lighting

● Stress lighting ● Traffic light reflectors ● Sports lighting

Chemical Composition (WT.%) of Aluminum Circles

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | – | – | 0.05 | 0.03 |

| 1060 | 0.250 | 0.350 | 0.050 | 0.030 | 0.030.- | – | 0.050 | 0.030 | 99.6 |

| 1070 | 0.200 | 0.250 | 0.040 | 0.030 | 0.030 | – | 0.040 | 0.030 | 99.7 |

| 1100 | Si+Fe:0.95 | 0.05-0.2 | 0.050 | – | – | 0.100 | – | 99.0 | |

| 3003 | 0.600 | 0.700 | 0.05-0.20 | 1.0-1.5 | – | – | 0.100 | – | remains |

| 5052 | 0.250 | 0.400 | 0.100 | 0.100 | 2.2-2.8 | 0.15-0.35 | 0.100 | – | remains |

| 8011 | 0.5-0.9 | 0.6-1.0 | 0.100 | 0.200 | 0.050 | 0.050 | 0.100 | 0.080 | remains |

Mechanical Properties of Aluminum Circles

| Temper | Thickness(mm) | Tensile Strength | Elongation(%) | Standard |

| HO | 0.36-6 | 60-100 | ≥ 20 | GB/T91-2002 |

| H12 | 0.5-6 | 70-120 | ≥ 4 | |

| H14 | 0.5-6 | 85-120 | ≥ 2 |

Grades, Characters, and Applications of Aluminum Circles

| Series | Temper | Alloy | Character | Application |

| 1 series | HO H12 H14 H22 H24 | 1050 | 1. Aluminium content>99%, excellent formability. 2. High reflectivity. 3. Stable performance for surface anodization. | 1. Ordinary cookware: extrusion pot lid, aluminium pot. 2. Lamp accessories: lampshade, downlights, laminate lights and street lights. 3. Indication signs and building materials: traffic signs, curtain walls, ceilings. |

| 1060 | ||||

| 1070 | ||||

| 1100 | ||||

| 3 series | 3003 | 1. Excellent formability. 2. High elongation, can be used in deep drawing process. 3. High grain grade, smooth surface and high reflectivity. | 1. Advanced cookware: non-stick pan, pressure cooker. 2. Lamp accessories: lampshade, downlights, laminate lights and street lights. 3. Indication signs and building materials: traffic signs, curtain walls, ceilings. | |

| 3004 | ||||

| 3005 | ||||

| 3105 | ||||

| 5 series | 5052 | 1. Low material density and low weight of finished product. 2. High tensile strength and elongation, good fatigue strength. 3. Higher grain grade and good surface finish. | 1.Advanced cookware: non-stick pan, pressure cooker. 2. Pressure vessel: pressure cooker, etc. | |

| 5754 | ||||

| 5083 | ||||

| 8 series | 8011 | 1. Excellent anodizing effect. 2. Stable performance and high surface quality. | Advanced cookware: can make pearl anodized cookware |

Our Products Are Widely Used For Making:

| ● Stock Pots | ● Fry Pans |

| ● Tea Kettles | ● Pressure Cookers |

| ● Rice Cookers | ● Pizza Pans |

| ● Electric Skillets | ● Restaurant Cookware |

| ● Coffee Urns | ● Bakeware |

| ● Steam Irons | ● Woks |

| ● Stainless Cookware Bottom Plates | ● Bread Makers |

Advantages of Aluminum Circles

- High formability

- Good processing performance

- Excellent elongation and tensile strength

- High plasticity, conductivity, and thermal conductivity

- Easy to take all kinds of pressure processing and extension or bending

- Suitable for gas welding, hydrogen welding, resistance welding, and brazing

Manufacture Process of Aluminum Circles

Aluminium Ingot/Master Alloys — Melting Furnace — Holding Furnace — D.C. Caster — Slab — Hot Rolling Mill — Cold Rolling Mill — Blanking (punching into the circle) — Annealing Furnace (unwinding) — Final Inspection — Packing — Delivery

Why Choose Aluminum Circle/Disc to Make Cookware?

As for aluminum circle for cookware, it is vital to pay attention to flowing properties, 1xxx and 3xxx series aluminum circle has good tensile strength property, good formability, it is easy to bend. Good corrosion resistance properties can ensure cookware use for a long time. Furthermore, it requests the aluminum disc/circle has good flatness, no oil stain, and no scratches on the surface.

What is the Price of an Aluminum Circle/Disc?

In recent years, the use of aluminum circles/discs has increased. The demand for aluminum circles/discs in the market is relatively large. It is a kind of product obtained through deep processing of aluminum plates, the surface is bright and beautiful, and it can be shaped and do the surface treatment. So, it is not expensive.

The price of aluminum circles/discs has something to do with the thickness. Generally speaking, circles of a common thickness (between 1.0mm and 8.0mm) have similar prices under the condition that they entail similar manufacturing processes. Such aluminum circles/discs can be obtained through relatively simple processes. Nevertheless, if the thickness surpasses 8mm, the price will go higher because the circles have to go through hot rolling, which involves raw material loss and the application of extra equipment. Therefore, it makes sense to think that the aluminum circles/discs price is related to thickness. In spite of this, there are exceptions. As said above, the price of an aluminum circle is also influenced by its manufacturing process. Not all thin circles (thickness below 8.0mm) are produced through cold rolling, some entail hot rolling, which increases their cost and eventually impacts their price.

About Company

CHAL Aluminium Corporation is a fully integrated aluminum company that provides all kinds of aluminum products and technical solutions. We are committed to being the leading supplier of aluminum plate, cast tooling aluminum plate, aluminum sheet (clad or bare), aluminum foil (clad or bare), aluminum strip (slit coil), aluminum circle/disc, aluminum coil.

Why Choose Us For Aluminum Circle?

- Pure primary ingot.

- Accurate dimensions and tolerance.

- Meet anodizing and deep drawing requirements.

- High-quality surface, the surface free from defects, oil stains, waves, scratches, and roll marks.

- Free samples are available for tests at first.

- Tension-leveling, oil-washing.

- Mill finish/ETD lubricant surface.

- With decades of production experience.

- Verified manufacturer, with quality assurance. The production process is approved by SGS and BV.

- After-sales service: our company promises rapid reply and responses in two days if a quality objection occurs, then we would arrange reshipment according to actual circumstances, if necessary, in the shortest time to make sure of your delivery.

Supply Ability

800/Tons Per Month

Packaging

Our products are packed and labeled according to the regulations and customer requests. Great care is taken to avoid any damage which might be caused during storage or transportation. The standard export packaging, plastic film or craft paper covered. Wooden case or wooden pallet is adopted to protect products from damage during delivery. In addition, clear labels are tagged on the outside of the packages for easy identification of the products and quality information.