This guide is designed to give you a better understanding of what aluminum heatsinks do, how aluminium heat sinks differ from other materials, and why they work so efficiently. If you’re trying to figure out the best cooler for your setup, the information below should give you a clearer idea of the best cooler to buy.

What is a heat sink for?

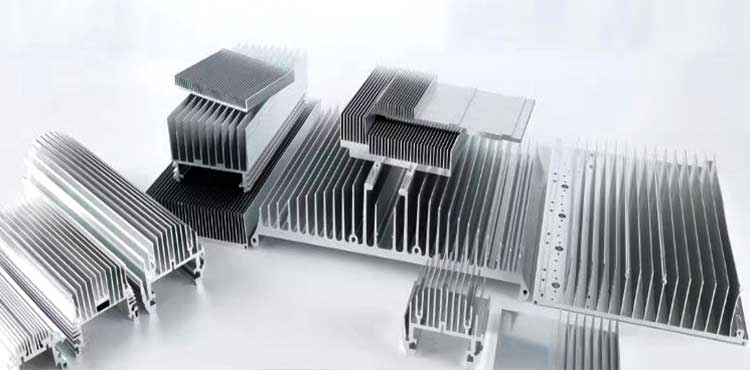

Heat sinks are a widely used cooling method for cooling parts or components that become hot when in use. Many types of electronic and mechanical devices or machinery use heat sinks to help them dissipate the heat they generate.

Heat sinks work by redirecting heat flow away from thermal equipment. They do this by increasing the surface area of the device. For heat sinks to work properly, they must have a higher temperature than their surroundings to transfer heat.

Strictly speaking, the definition of a heat sink can include any substance or device that absorbs or dissipates heat—especially when heat is not required or conducive to performance. After all, in extreme cases, electrical or mechanical heat build-up can lead to complete system failure, fire, explosion or damage. In actual radiator applications, the radiators of general electronic products – CPU radiators are different from automobile radiators. It has a different shape but works the same way.

Type of heat sink

Heat sinks are almost always made of metal, most commonly copper heat sinks or aluminium heat sinks. One of the most common designs of heat sinks is the familiar “finned” layout. Other alternative versions use pins, stamping, and various other forming techniques to increase the surface area and overall heat transfer rate of the heat sink.

Most heat sinks are passive. This means that as long as they remain in direct contact with the specific part or assembly in question, they will naturally conduct heat away from the source without any further equipment or process.

Which material is the best for heat sinks?

The heat dissipation performance of the heat sink has a positive relationship with the thermal conductivity of the materials used. Thermal conductivity, on the other hand, measures the ability of a metal to conduct heat. This property varies with different types of metals and is important to consider in applications where high operating temperatures are common.

In pure metals, thermal conductivity remains roughly constant with increasing temperature. In alloys, however, the thermal conductivity increases with temperature.

|

Common metals ranked by thermal conductivity Rank Metal Thermal Conductivity [BTU/(hr·ft⋅°F)] |

||

|

1 |

Copper |

223 |

|

2 |

Aluminum |

118 |

|

3 |

Brass |

64 |

|

4 |

Steel |

17 |

|

5 |

Bronze |

15 |

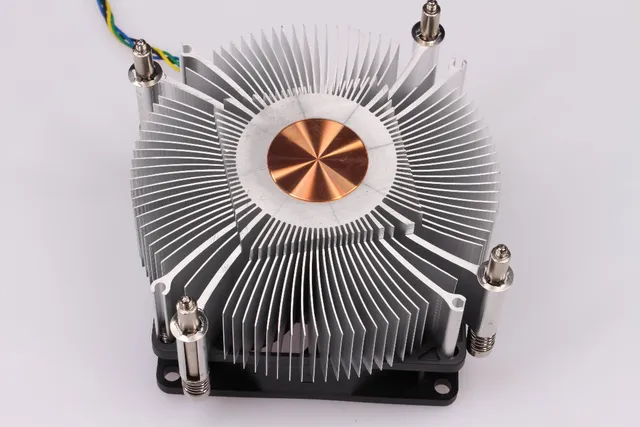

Copper is the metal material with the best heat dissipation performance, so copper has been an excellent material for heat sinks for a long time. But now more and more radiators choose to use aluminum alloy as the processing material of the heat sink, why is this?

Although the aluminum radiator cannot surpass the copper radiator due to the heat dissipation performance of the material, it has excellent high-pressure resistance and high thermal compressive strength of metal materials.

The aluminum heat sinks can dissipate heat faster. High efficiency is the biggest advantage of aluminium radiators. So we don’t need to take up too much space to make the best performance of the radiator. And spraying electrostatic powder coating on the surface of the aluminum radiator will make its surface produce a more beautiful visual experience.

Which aluminum alloys are generally used for aluminum heat sinks?

As mentioned above, the requirements of the heat sink aluminum alloy are better heat dissipation performance and better cutting performance. Based on these two reasons, the metal choice of the aluminum radiator is 6063 aluminum alloy. Because this aluminium grade can meet these two conditions, there is another cost-effective factor, and the cost is relatively low.

This is not a choice made without basis, but the best solution obtained by CHAL over the years according to the requirements of customers. The biggest advantage of the 6063 aluminum heat sinks is that it not only has excellent performance but also the price is lower than the radiator of the same performance.