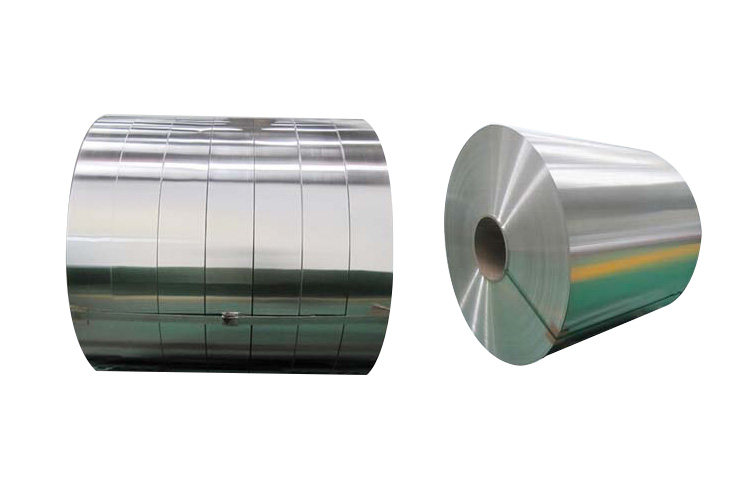

Aluminum Strip

Aluminum strip is the common name for aluminum sheet and foil in rolls with a thickness > 0.2mm and a width of 20mm to 100mm. The common name for aluminium strip that is produced in small strip widths is usually split strip. Aluminum sheets are cut into a required by slitting tooling, the raw material of the aluminum strip is pure aluminum or aluminum alloy hot rolled cast-rolling aluminum coil and hot-rolled coil. A cold-rolled machine to form different thicknesses and widths of the rolling sheet and aluminum coil, and then the vertical cutting and slitting machine for different widths of the strip. If the thickness is <0.2mm, we call it an aluminum foil strip or aluminum foil coil.

CHAL is the leading manufacturer and exporter of aluminum strips in China. Our aluminum strip is manufactured according to standard procedures, which are studied to get high performances from every application field. The common characteristic of all CHAL’s products is versatility, this is the reason why you can use our aluminium strip with excellent results in your professional operations. If you need specific consultation about the uses of aluminum strips, please contact us without hesitation.

Product Details of Aluminum Strip

| Alloy | 1050, 1060, 1070, 1100, 1035, 1200, 2024, 3003, 3004, 3104, 5005, 5052, 5056, 5754, 6061, 7075, 8011, etc. |

| Temper | O, H14, H18, H24, T |

| shapes | Coil |

| Diameter | 15mm-1200mm (can be customized) |

| Width | 10mm-100mm |

| Thickness | 0.014mm-3mm |

| Tensile strength | ≥120 mpa |

| Yield strength | < 95 N/mm2 |

| Elongation | > 20% |

| Tolerances | As per your requirements |

| Surface | Mill Finish, Plain, Color Coated |

| Standard | GB/T, ASTM, EN |

| Further Fabrication | Deep Drawing, Anodizing |

| MOQ | 3 tons |

| Price terms | FOB, CRF, CIF |

| Payment terms | 30% deposit in advance,70% balance payment by TT or LC |

| Loading Port | Any port in China, Shanghai & Ningbo & Qingdao |

| Delivery Methods | 1. By sea: Any port in China; 2. By train: Chongqing(Yiwu) International Railway to Middle Asia-Europe |

| Packing | Wooden pallets suitable for long-distance sea transportation |

Features of Aluminum Strip

- Excellent roll forming and welding properties

- High strength combined with high elongation

- Extremely consistent material characteristic

- Excellent corrosion properties

- Special thermo-mechanical performance

- Good adhesion between aluminum

- Higher creep resistance at elevated temperature

- Prominent formability

- Excellent flexibility and better bending properties

Aluminum Strip Grade & Application Fields

| Alloy | Application field | |

| 1xxx | 1050 | Insulation, food industry, decoration, lamp, traffic signs, etc. |

| 1060 | Fan blade, Lamps and lanterns, Capacitor shell, Auto parts, Welding parts, etc | |

| 1070 | Capacitor, Rear panel of vehicle refrigerator, charging point, heat sink, etc | |

| 1100 | Cooker, building material, printing, heat exchanger, bottle cap, etc | |

| 2xxx | 2A12 2024 | Aircraft structures, rivets, aviation, machinery, missile components, the card wheel hub, propeller components, aerospace parts, car parts and various other structural parts. |

| 3xxx | 3003 3004 3005 3105 | Aluminium curtain wall panel, Aluminium Ceiling, Electric cooker bottom, TV LCD backboard, storage tank, curtain wall, building construction panel heat sink, billboard. Industrial floor, air conditioning, refrigerators radiators, Make-up board, Prefabricated house, etc. |

| 5xxx | 5052 | Marine and transportation material, railway carriage’s inner and outer cabinet, oil and chemical industry storage device, equipment and medical device panel, etc. |

| 5005 | Marine applications, bodies of boats, buses, trucks and trailer. Curtain wall panel. | |

| 5086 | Shipboard, deck, bottom and edge panel, etc. | |

| 5083 | Tanker, oil storage tank, drilling platform, shipboard, deck, bottom, welded parts and edge panel, railway carriage’s board, automotive and aircraft panel, cooling device and automotive molding, etc. | |

| 5182 | ||

| 5454 | ||

| 5754 | Tanker body, marine facilities, pressure container, transportation, etc. | |

| 6xxx | 6061 6083 6082 | Railway inside and outside parts, board and bedplate. Industry molding Highly stressed applications include Roofing construction, transportation, and marine as well as mould. |

| 6063 | Auto parts, architectural fabrication, window and door frames, Aluminium furniture, electronic components as well as various consumer durable products. | |

| 7xxx | 7005 | Truss, rod/bar and the container in transportation vehicles; Large-sized heat exchangers |

| 7050 | Molding (bottles) mode, ultrasonic plastic welding mold, golf head, shoe mold, paper and plastic molding, foam molding, lost wax mold, templates, fixtures, machinery and equipment | |

| 7075 | Aerospace industry, military industry, electronic, etc | |

- Refrigerator

- Commercial freezer

- Cable wrap

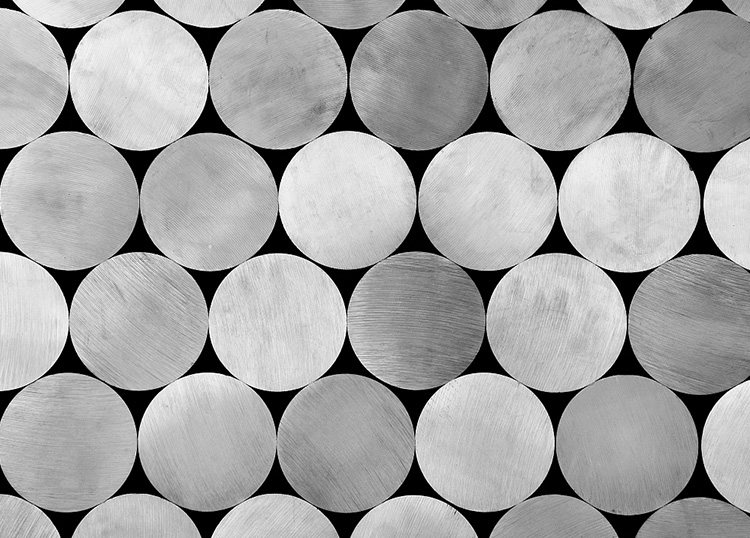

- Capacitor

- Anti-theft strips

- Aluminum/plastic composite pipes

- Shoe eyelet

Aluminum strips are wide-ranging used in the building industry, industrial constructions, air-conditioning and ventilation, the automotive industry, and equipment components in diverse products.

Aluminum Strip Production Process

Aluminium Ingot/Master Alloys — Melting Furnace — Holding Furnace — Slab — Hot Rolling — Cold Rolling — Slitting machine (vertical cutting to narrow width) — Annealing Furnace (unwinding) — Final Inspection — Packing — Delivery

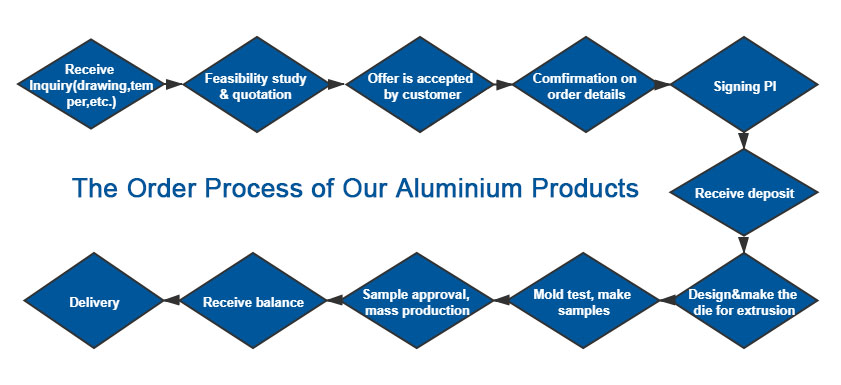

Order Process of Aluminum Strip

We have a strict and professional QC of production:

1. Before producing:

- Assurance of compliance with the standard and material

- According to the customer’s order

- Making production plan according to the customer’s order

- Starting producing after receiving the payment from the customer

2. Finished production:

- Chemical test and mechanical test by our quality department

- Visual examination

- Thickness measurement (Continous Ultrasonic)

- Length dimension control

- Flatness, straightness, visual & dimension check of edge

- Weight control

- Marking

3. Checking before delivery:

- Checking for packages

- Certificate of Compliance

- Checking for shipping marks and quantity

1050 1060 1070 1350 Aluminum Strip for Transformer

1050 1060 1070 1350 aluminum trip can be used for variable transformers like low or high-voltage transformer winding, high-frequency transformers, step-up or down-voltage transformers, etc.

The transformer aluminium strip for electrical coil application ranges from 0.3mm to 2.5mm. The alloy 1050 (99.50% aluminum) can be used to meet the minimum industry requirements for strip conductors. And it is closely controlled to ensure smooth, substantially burr-free edges and strip-size availabilities are in capacities exactly equivalent to those of standard copper wire sizes.

About Company

CHAL Aluminium Corporation is a fully integrated aluminum company that provides all kinds of aluminum products and technical solutions. We are committed to being the leading supplier of aluminum plate, cast tooling aluminum plate, aluminum sheet(clad or bare), aluminum foil(clad or bare), aluminum strip(slit coil), aluminum circle/disc, and aluminum coil.

Our Advantages

- Pure primary ingot

- Accurate dimensions and tolerance

- Meet anodizing and deep drawing requirement

- High-quality surface: the surface is free from defects, oil stains, waves, scratches, roll mark

- High flatness

- Tension-leveling, oil-washing

- Mill finish/ETD lubricant surface

- With decades of production experience

Supply Ability

2000/Tons Per Month

Packaging

Our products are packed and labeled according to the regulations and customer requests. Great care is taken to avoid any damage which might be caused during storage or transportation. The standard export packaging, plastic film or craft paper covered. Wooden case or wooden pallet is adopted to protect products from damage during delivery. In addition, clear labels are tagged on the outside of the packages for easy identification of the products and quality information.