With the continuous expansion of the application range of aluminum, the development of the industry is facing new opportunities. Aluminum used in the air-conditioning industry is one of the important markets for promoting the application of aluminum. However, this market has not gained a large blue ocean market like aluminum for new energy vehicles and aluminum for photovoltaic as soon as it is discovered. For a long period, it is still in the exploration stage of technology research and product application.

Even in a certain period, there were many debates in public opinion, such as “Aluminum instead of copper for air-conditioning connecting foils, whether it is technological innovation or deception”. This article will tell you how likely it is that “aluminum foils for air conditioning” can replace “copper”.

Why Advocate “Replacing Copper with Aluminum” in the Air-conditioning Industry?

- Cost reduction is the biggest driver. The shortage of copper resources and the high copper price have seriously restricted the competitive advantage of the air-conditioning industry.

And aluminum is a good alternative material. The overall density is on a downward trend. Due to factors such as pipe diameter refinement and pipe diameter refinement in the air-conditioning industry, the trend of aluminum replacing copper is becoming more and more obvious.

- Since the world is advocating to protect the environment, it is an inevitable trend to upgrade the energy efficiency of home appliances. The use of aluminum in the air-conditioning industry is conducive to further reducing carbon emissions during production and use, ensuring the stability and risk resistance of the home appliance supply chain;

- Strengthen recycling. In the recycling process of the air-conditioning heat exchanger, the separation process is complicated and requires a lot of manpower and material resources, which not only pollutes the environment but also easily wastes resources. But as an excellent recyclable material, aluminum can better prevent the environment from being polluted.

Advantages of “Aluminum for Air Conditioning”

In terms of performance, aluminum is the preferred resource to replace copper as a functional material for electrical and thermal conductivity. The conductivity of aluminum is about 60% of that of copper, second only to silver, copper, and gold. The thermal conductivity system is about 55% of that of copper, and the specific heat is 2.33 times that of copper.

Secondly, aluminum has good processing performance, large reserves on the earth, and a low price. It is an ideal material to replace copper.

To this end, the replacement of copper with aluminum in the air-conditioning field is a solution worthy of continuous research and advancement. However, the current air-conditioning ‘aluminum-to-copper’ is still in the gestation period and wait-and-see period, and more people need to devote themselves to this field study.

As early as some previous market analyses, there are some data: from the perspective of household air conditioners, the amount of aluminum used in household air conditioners of about 1.5 hp in the market is about 3KG.

Judging from the situation of supporting manufacturers, aluminum replaces copper for supporting products such as elbows and valves for air conditioners, and the aluminum alloy frame of household air conditioners is currently increasing.

The demand for aluminum for commercial air conditioners is about 8KG-30KG; some data also show that the scale of “aluminum-replacement-copper” air-conditioning products produced by air-conditioning companies is increasing. It is also trying to carry out the research and development and promotion of the “aluminum-to-copper” technology. In addition, the reduction of the diameter and weight of copper pipes has also become the trend of research and innovation in air-conditioning enterprises. It can be seen where its market potential lies!

To a certain extent, whether “aluminum instead of copper” can be applied in a large area depends on two core elements, namely the technical maturity of aluminum tubes in the application of air conditioning and refrigeration equipment and the acceptance of aluminum tube air conditioners by users.

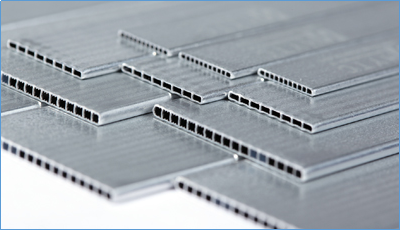

Ding Guoliang, a professor at Shanghai Jiaotong University in China and chairman of the Refrigeration and Air Conditioning Heat Exchanger Technology Alliance, pointed out in the report “Application Status and Development Trend of Aluminum Heat Exchangers in the Home Appliance Industry” that in all-aluminum heat exchangers for air conditioners, aluminum tubes Replacing copper tubes is the general trend, especially all-aluminum microchannel heat exchangers have more development potential.

Zhao Yang, the chief engineer of China Household Electrical Appliances Research Institute, made a special report entitled “Discussion on Standards and Testing Technology of Aluminum Air Conditioning Heat Exchangers”. Zhao Yang believes that in the home appliance industry, the advantages of replacing copper with aluminum outweigh the disadvantages. It can be seen that more people are optimistic about the “aluminum instead of copper” in the air-conditioning industry.