Aluminum coil is a highly versatile material that finds widespread use in various industries due to its unique properties and wide range of available grades. Each grade of aluminum coil offers specific characteristics that make it suitable for specific applications. In this comprehensive article, we will delve into the diverse world of aluminum coil grades, highlighting their properties and exploring their applications across different industries.

1000 Series Aluminum Coil

The 1000 series, also known as pure aluminum, is characterized by its high aluminum content, with a purity exceeding 99.00%. The most common grades in this series are 1050 and 1060. These coils are widely used in industries due to their cost-effectiveness and ease of production. They find applications in:

- Construction: Roofing, siding, gutters, and general architectural uses.

- Industrial: Heat exchangers, storage tanks, and ductwork.

- Transportation: Trailers, truck bodies, and vehicle panels.

- Packaging: Cans, foils, and food containers.

2000 Series Aluminum Coil

The 2000 series aluminum coil is characterized by high hardness, among which the content of copper element is the highest, about 3-5%, and the typical products are 2A16 and 2A06. These coils are primarily used in aerospace applications, where their strength and durability are crucial. Their applications include:

- Aerospace: Aircraft structural components, fuselage panels, and wings.

- Industrial: Manufacturing of high-stress parts and precision components.

- Automotive: Critical components requiring strength and durability.

3000 Series Aluminum Coil

The 3000 series, represented by grades such as 3003 and 3A21, is alloyed with manganese, typically ranging from 1.0-1.5%. This series is known for its excellent resistance to corrosion, making it ideal for applications in moist environments. The 3000 series aluminum coils are widely used in:

- Architecture: Facade cladding, decorative elements, and curtain walls.

- Appliances: Refrigerator panels, air conditioning units, and heat exchangers.

- Transportation: Vehicle bodies, bus flooring, and marine applications.

4000 Series Aluminum Coil

The 4000 series is primarily represented by grade 4A01. These coils have a high silicon content, typically ranging from 4.5-6.0%. The 4000 series finds applications in various industries due to its unique properties, including:

- Construction: Building materials, architectural components, and roofing.

- Machinery: Machined parts, forgings, and welding applications.

- Heat transfer: Heat exchangers, radiators, and cooling systems.

5000 Series Aluminum Coil

The 5000 series encompasses grades such as 5052, 5005, 5083, and 5A05. These coils are aluminum-magnesium alloys, known for their excellent corrosion resistance. They find applications in industries such as:

- Marine: Shipbuilding, boat hulls, and offshore structures.

- Aerospace: Aircraft fuel tanks, wing panels, and structural components.

- General Industry: Automotive parts, pressure vessels, and storage tanks.

6000 Series Aluminum Coil

The 6000 series, with grade 6061 being the most prominent, is alloyed with magnesium and silicon. These coils offer a good balance of strength, formability, and corrosion resistance, making them suitable for a wide range of applications, including:

- Automotive: Car frames, wheels, and engine components.

- Construction: Structural framing, bridges, and scaffolding.

- Consumer Goods: Furniture, sporting equipment, and electrical enclosures.

7000 Series Aluminum Coil

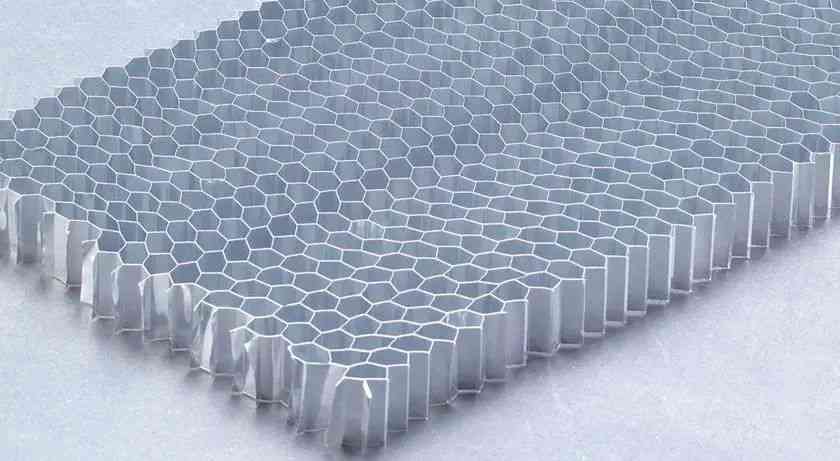

The 7000 series aluminum coil is known for its exceptional strength and toughness. The representative grade in this series is 7075, which contains zinc as the primary alloying element. The 7000 series coils are widely used in industries that require high-performance materials, including:

- Aerospace: Due to its high strength-to-weight ratio and excellent fatigue resistance, 7000 series coils are used in the production of aircraft structures, wings, fuselage frames, and rotor blades.

- Defense: Military vehicles, armor plating, and weapon systems benefit from the superior strength and durability of 7000 series aluminum coils.

- Sports Equipment: High-performance bicycles, rock climbing gear, and tennis rackets often incorporate 7000 series aluminum for its lightweight and durable properties.

- Automotive: Certain high-end automotive components, such as suspension systems, chassis, and wheels, utilize 7000 series coils to enhance strength and reduce weight.

8000 Series Aluminum Coil

The 8000 series, with grade 8011 being the most common, is mainly used for aluminum foil and packaging applications. This series offers excellent formability and heat resistance, making it suitable for various industries, including:

- Packaging: Aluminum foil for food and beverage packaging, pharmaceutical packaging, and cigarette packaging.

- Heat Exchangers: Aluminum fins for air conditioning systems, radiators, and heat exchanger coils.

- Electrical Conductors: Aluminum coil is used for the production of transformer windings and electrical cables.

- Household Items: Cookware, kitchen utensils, and decorative elements benefit from the formability and corrosion resistance of 8000 series aluminum.

Summary

Aluminum coil grades offer a wide range of properties and applications across various industries. From the pure aluminum of the 1000 series to the high-strength alloys of the 8000 series, each grade brings its unique set of characteristics to meet specific requirements. The versatility of aluminum coil allows it to be utilized in diverse sectors such as construction, transportation, aerospace, packaging, and more. Manufacturers, engineers, and designers can leverage the properties of different grades to achieve exceptional results in their respective fields. Whether it’s for its lightweight construction, corrosion resistance, or formability, aluminum coil grades have proven indispensable in countless applications. CHAL, as a professional aluminum coil manufacturer, provides high-quality products and services to every client. Contact us now, and you’ll get a reliable business partner and aluminum coil supplier in China.