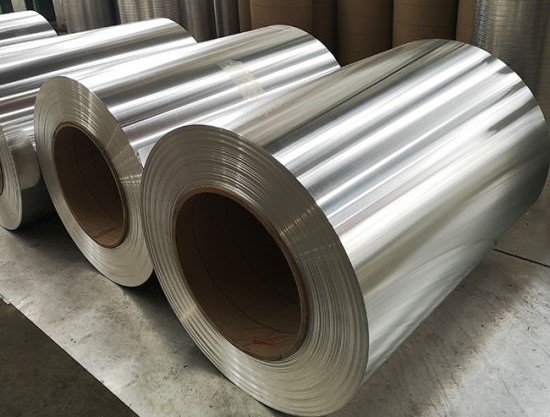

Aluminum coil is a sheet of aluminum that has been rolled into a coil. It is a versatile material that is used in a wide variety of applications. The different types of aluminum coil are classified by the alloying elements that are added to the aluminum. These alloying elements give the aluminum coil different properties, such as strength, ductility, and corrosion resistance. Here we’ll delve into the different types of aluminum coils and their applications, shedding light on their unique properties and advantages.

5 Common Different Types of Aluminum Coil and Their Applications

1000 series aluminum coil

- This is the most common type of aluminum coil and is used for a variety of applications, including packaging, building materials, and electrical components.

- It is also the most affordable type of aluminum coil.

- The most common alloy in this series is 1100, which is 99% pure aluminum. It is a soft and ductile material that is easy to work with. It is also very resistant to corrosion.

- Applications:

- Packaging: Used to make beverage cans, food containers, and other packaging materials.

- Building materials: Used to make siding, roofing, and other building materials.

- Electrical components: Used to make conductors, transformers, and other electrical components.

- Foil: Used to make food packaging, electrical insulation, and other thin materials.

- Extruded products: Used to make window frames, door frames, and other extruded products.

- Stamping: Used to make beverage cans, food containers, and other stamped products.

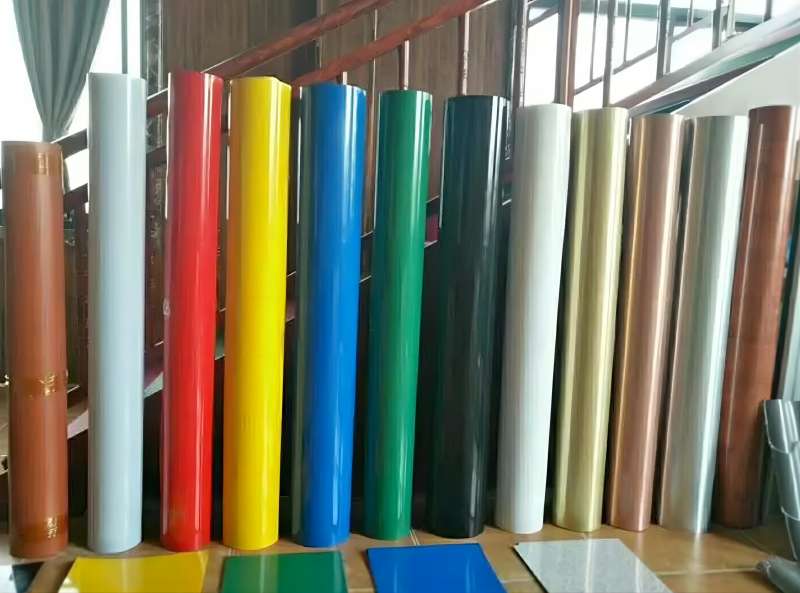

- Anodizing: Used to create a decorative and protective finish on the aluminum surface.

- Machining: Used to create precision parts from aluminum.

2000 series aluminum coil

- This type of aluminum coil is stronger and more durable than 1000 series aluminum coil.

- It is also more resistant to corrosion.

- The most common alloy in this series is 2024, which is 99.5% pure aluminum with 4.5% copper. It is a strong and lightweight material that is often used in aircraft construction.

- Applications:

- Transportation: Used to make car parts, boat hulls, and other transportation components.

- Machinery: Used to make machine parts, tools, and other machinery components.

- Chemical processing: Used to make tanks, pipes, and other equipment for chemical processing.

- Marine applications: Used to make ship hulls and other marine equipment.

- Sports equipment: Used to make bicycles, skis, and other sports equipment.

- Architectural applications: Used to make curtain walls, window frames, and other architectural components.

3000 series aluminum coil

- This type of aluminum coil is heat-treatable, which means that it can be strengthened by heat.

- It is also more resistant to wear and tear than other types of aluminum coil.

- The most common alloy in this series is 3003, which is 99.5% pure aluminum with 0.5% manganese. It is a strong and ductile material that is easy to work with.

- Applications:

- Aircraft: Used to make aircraft parts, such as fuselages and wings.

- Sports equipment: Used to make bicycles, skis, and other sports equipment.

- Marine applications: Used to make ship hulls and other marine equipment.

- Structural applications: Used to make bridges, buildings, and other structural components.

- Tanks and pressure vessels: Used to make tanks and pressure vessels that need to withstand high pressure.

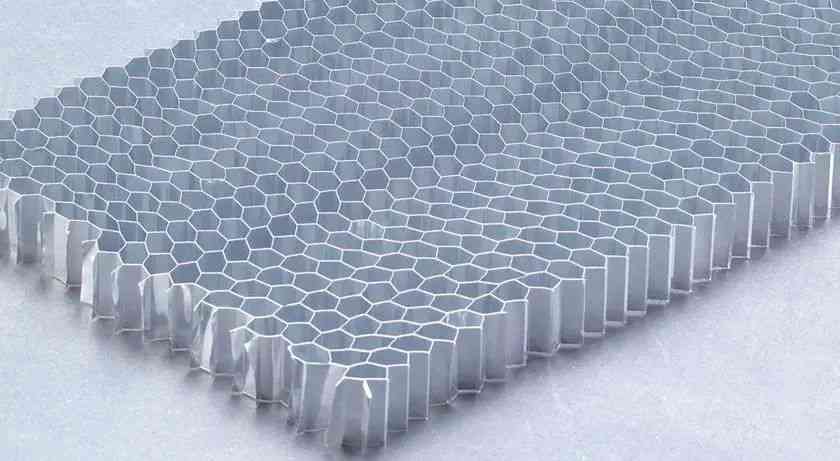

- Heat exchangers: Used to make heat exchangers that transfer heat efficiently.

5000 series aluminum coil

- This type of aluminum coil is the most ductile type of aluminum coil.

- It can be easily bent and formed into different shapes.

- The most common alloy in this series is 5052, which is 99.5% pure aluminum with 0.5% magnesium. It is a soft and ductile material that is easy to work with. It is also very resistant to corrosion.

- Applications:

- Beverage cans: Used to make beverage cans and other stamped products.

- Building materials: Used to make siding, roofing, and other building materials.

- Chemical processing: Used to make tanks, pipes, and other equipment for chemical processing.

- Marine applications: Used to make ship hulls and other marine equipment.

- Heat sinks: Used to dissipate heat from electronic components.

- Solar panels: Used to make solar panels that absorb sunlight and convert it into electricity.

7000 series aluminum coil

- This type of aluminum coil is the strongest type of aluminum coil.

- It is also very resistant to corrosion.

- The most common alloy in this series is 7075, which is 98% pure aluminum with 1.5% zinc, 0.6% magnesium, and 0.3% copper. It is a very strong and lightweight material that is often used in aerospace applications.

- Applications:

- Structural applications: Used to make bridges, buildings, and other structural components.

- Marine applications: Used to make ship hulls and other marine equipment.

- Aerospace applications: Used to make aircraft parts, such as fuselages and wings.

- Sports equipment: Used to make bicycles, skis, and other sports equipment.

- Chemical processing: Used to make tanks, pipes, and other equipment for chemical processing.

Conclusion

Aluminum coil is a versatile material that is used in a wide variety of applications. The different types of aluminum coil are classified by the alloying elements that are added to the aluminum. These alloying elements give the aluminum coil different properties, such as strength, ductility, corrosion resistance, and thermal conductivity.

The choice of aluminum coil for a particular application will depend on the specific requirements of the application. For example, if the application requires a strong and lightweight material, then a 7000 series aluminum coil would be a good choice. If the application requires a material that is resistant to corrosion, then a 1000 series aluminum coil would be a good choice.