Aluminum profiles are by-products usually for structural purposes. It is possible to distinguish 4 types of profiles according to their use: construction, architectural and industrial.

Construction profiles: The profiles offer high bending and torsional stiffness despite their low net weight. Solar panel frames, structures for working platforms and scenarios, etc.

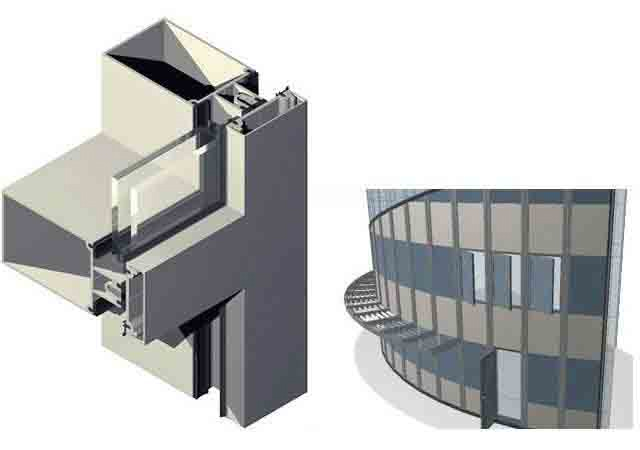

Architectural profiles: For this application is very important the surface finish. Architectural profiles are used to make frameworks for windows, doors and curtain walls.

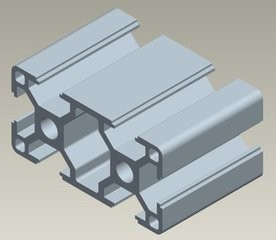

What Are Industrial Aluminum Profiles?

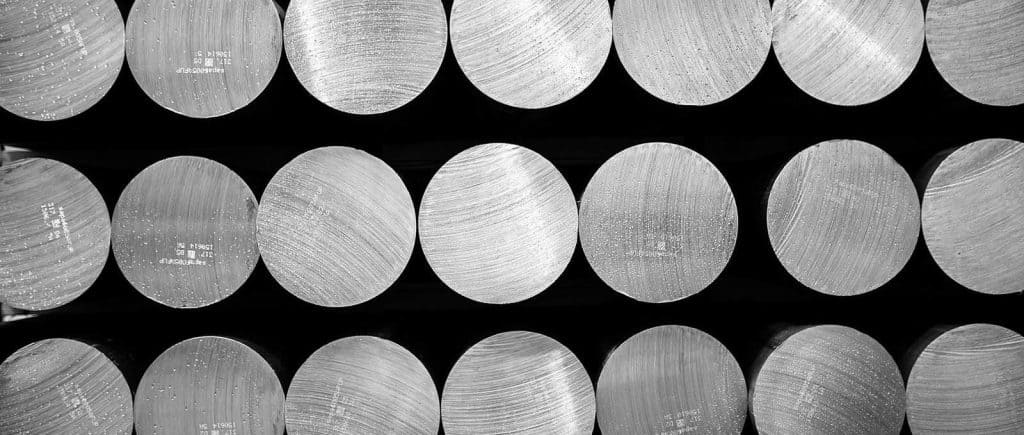

The industrial aluminium profile is an alloy material with aluminum as the main component. Aluminum rods are hot-melted and extruded to obtain aluminum materials with different cross-sectional shapes. However, the different proportions of alloy added will create different mechanical properties and applications. Generally speaking, industrial aluminum profiles refer to all-aluminum profiles except for building doors and windows, curtain walls, interior and exterior decoration, and aluminum profiles for building structures. There are characteristics such as modularization, easy deep processing and assembly into different aluminum profile application products, diverse functions, corrosion resistance, and beautiful appearance.

Classification of Industrial Aluminum Profiles

Industrial aluminum profiles are classified by surface treatment. This method can classify aluminum into five categories. They are anodized aluminum profiles, electrophoretic painted aluminum profiles, wood grain transfer aluminum profiles, powder-coated aluminum profiles, and planed aluminum profiles. The planed aluminum profiles can be divided into two categories: mechanical planing and chemical planing. Aluminum profile manufacturers seldom choose it due to its expensive cost.

There are 5 categories that are based on the application and function of aluminum profiles.

- Architectural aluminum profiles: This profile is classified into door and window aluminum and curtain wall aluminum profiles.

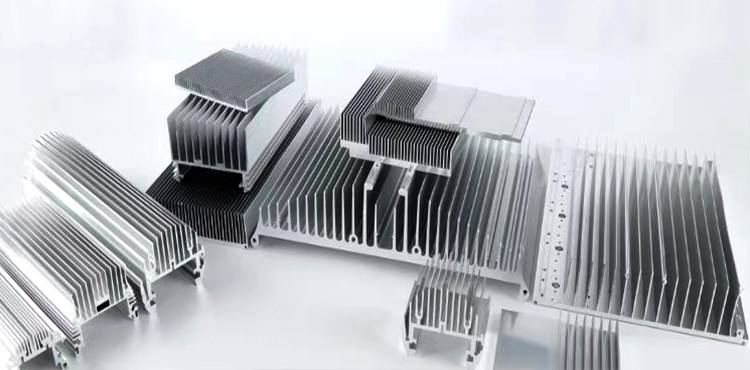

- Radiator aluminum profiles are generally used for CPU heat dissipation.

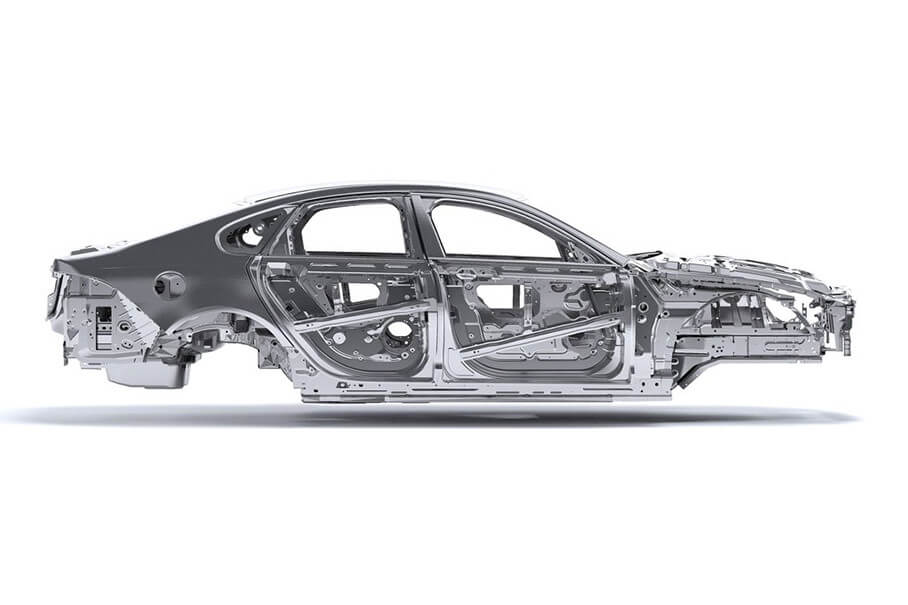

- Industrial aluminium profiles are used in the automation industry of machinery and equipment, which can be processed into various aluminum profile frames, equipment covers, mechanical protective fences, assembly line workbenches, display stands, partitions, etc. due to their rich specifications.

- Rail aluminum is mostly used for high-tech rails.

- The last type is the production and manufacturing of installation aluminum profiles: This kind of aluminum is mainly used for installing various exhibition decorative paintings with rich colors and low cost.

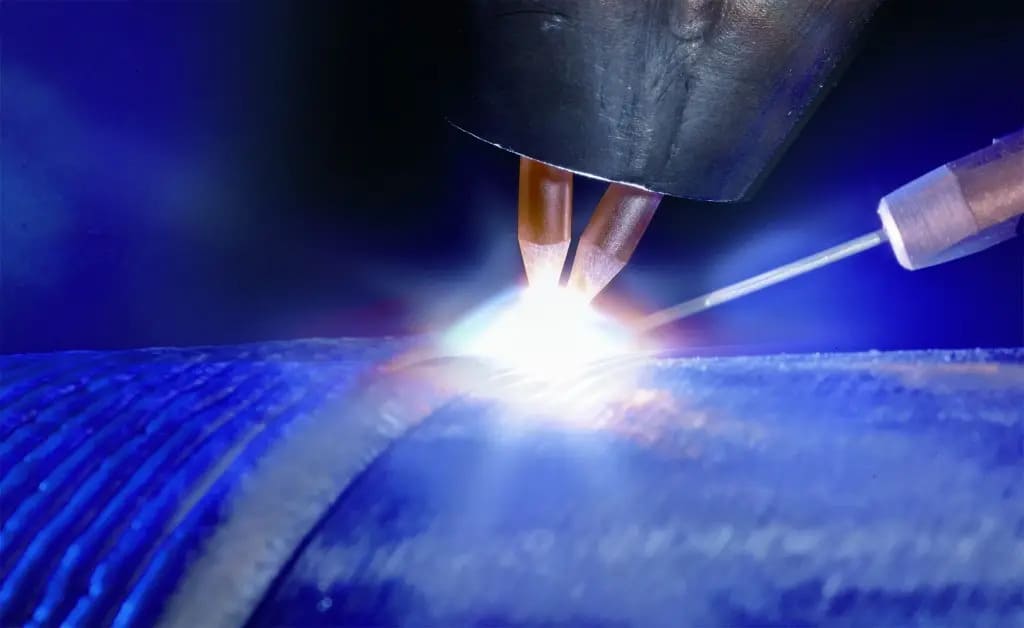

What Equipment Will be Used in Processing?

- Equipment of extrusion

Metal extrusion is an important method of metal plastic pressure forming. Its important feature is that metal ingots can be processed into tubes, rods, and profiles at one time.

- Stretching and straightening

Straightening hydraulic presses are mainly used for drawing, turning, bending, and stamping sheet metal parts, and can also be used for general stamping processes. Straightening hydraulic press can increase punching buffer, punching, and moving work according to different requirements. In addition to forging, straightening hydraulic presses can also be used for straightening, pressing, and packaging.

- Cutting machines

Cutting machines are used to cut industrial aluminum profiles. Nowadays, the length of industrial aluminium profiles is relatively long. We need to cut the profiles to custom sizes. Cutting machines include double-head and laser cutting machines. The consumption of cutting loss of ordinary cutting machines is 0.5mm, while the precision is relatively high.

- Tapping machines

Tapping machines are one of the most widely used internal threading machines. Tapping machines can include desktop tapping machines – semi-automatic desktop tapping machines, vertical tapping machines, and horizontal tapping machines.

- Punch machine of aluminum

When we assemble the frame, some industrial aluminum profiles need to be drilled, so we need a punch, which can not only drill holes but also bend sheets or profiles.

Connection of Industrial Aluminum Profiles

- Same series. Aluminum profiles are classified into national standards and European standards. These two major standard systems represent that the section of the profile and the accessories are different. Therefore, if the profiles are to be connected, it is necessary to ensure that the profiles belong to the European standard or the national standard.

- Same slot. If we connect different specifications of aluminum profiles, in addition to the same standard system, it is necessary to ensure that the slot is the same so that the size of the accessories can be the same, and we can carry out the installation.

- Same processing. The outer connection can ignore this. If it is an inner connection, you need to consider whether the processing is the same. Including the processing method, the type of hole, the size of the hole, the position of the tapping, the depth of the thread, and so on. It is easy to install if all of those are the same.

- The same strength of accessories. When industrial aluminium profiles are connected, no matter what kind of accessories are used, it is necessary to ensure that the strength of the accessories used is the same. Because the accessories are made of many kinds of materials, the connection strength is different. For the stability of the connection, it is essential to check whether the materials used for the accessories are the same.